Rather than fabricating an entirely new plate for a new windlass install, I was thinking of filling in the void left by my last windlass and then re-drilling the appropriate holes to install the new windlass. I believe the backer board used in the prior install is Taco Marine "Plastic Lumber", though I'm not absolutely certain (is there a way to tell?). It's possible it's Starboard, but it is two sheets bonded to each other as well as to other shims, and I've read that Starboard does not bond well, which leads me to believe that it is not Starboard.

Either way, could I simply replace the SS top plate (on which the windlass will rest), then fill the former windlass' void with epoxy resin or fiberglass, wait for it to cure, then drill the appropriate holes for the new windlass, per its template?

I'm not familiar with plastics and how they relate to resins and don't know if this would work, but if it could, it would save me much time and effort (as well as money) as I wouldn't have to purchase new Starboard or Plastic Lumber and rebuild the entire piece.

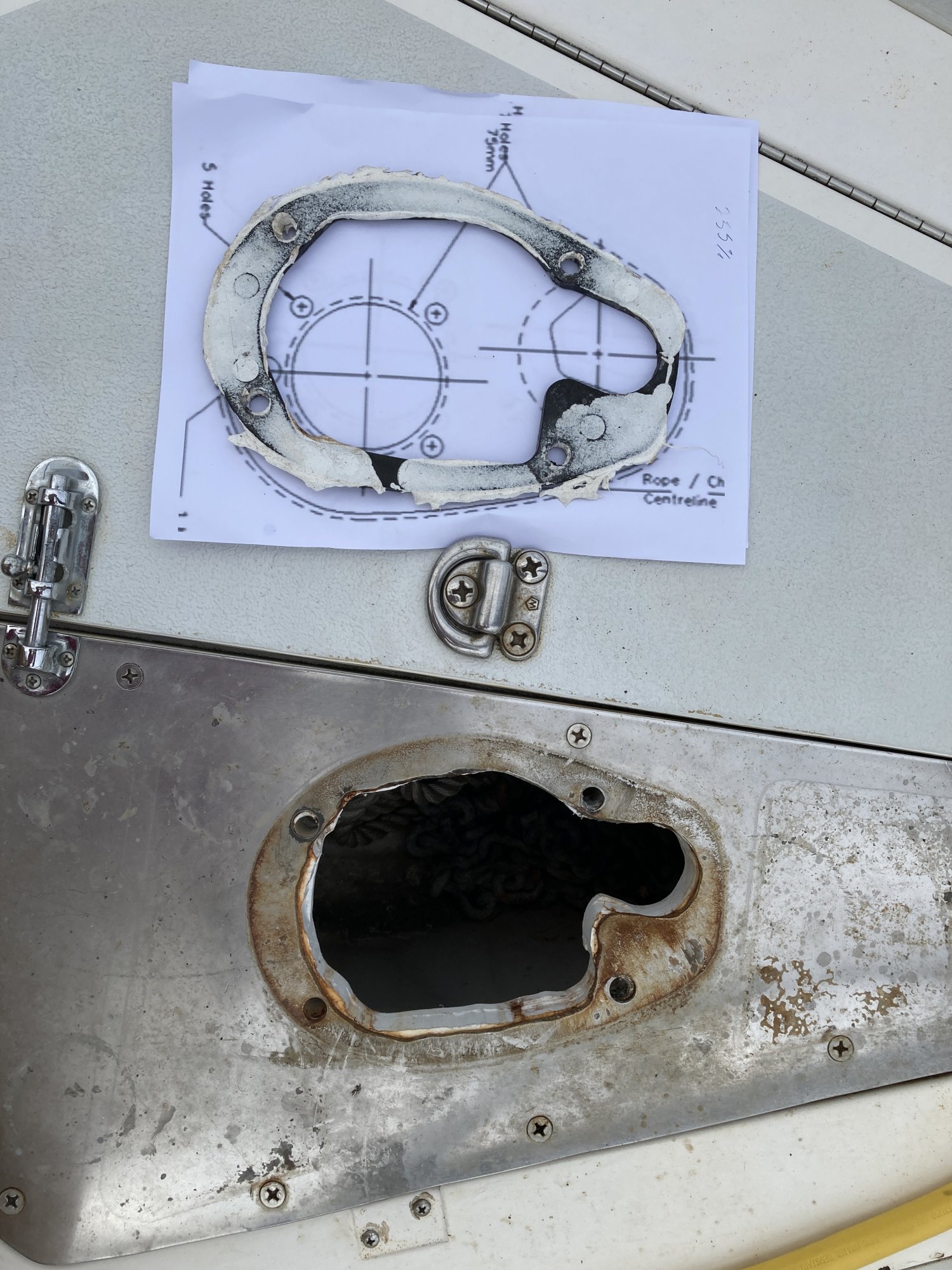

Exterior picture: Port side is anchor locker hatch, starboard side is mounting plate for windlass: 1/8" stainless steel plate on top of 1" plastic sheet (3/4" bonded to 1"4" sheet to make 1" combined).

Exterior picture showing bonded plastic sheets and SS plate thickness.

Under side (locker side) of windlass mounting plate, showing additional framing/shims attached to 1" plastic sheet. Outer holes are where bolts anchor top plate to anchor locker (via large washers overlapping flange in anchor locker).

Exterior view: Empty bolt holes show where bolts and 1" washers (also pictured) attach windlass mounting plate to anchor locker.

Either way, could I simply replace the SS top plate (on which the windlass will rest), then fill the former windlass' void with epoxy resin or fiberglass, wait for it to cure, then drill the appropriate holes for the new windlass, per its template?

I'm not familiar with plastics and how they relate to resins and don't know if this would work, but if it could, it would save me much time and effort (as well as money) as I wouldn't have to purchase new Starboard or Plastic Lumber and rebuild the entire piece.

Exterior picture: Port side is anchor locker hatch, starboard side is mounting plate for windlass: 1/8" stainless steel plate on top of 1" plastic sheet (3/4" bonded to 1"4" sheet to make 1" combined).

Exterior picture showing bonded plastic sheets and SS plate thickness.

Under side (locker side) of windlass mounting plate, showing additional framing/shims attached to 1" plastic sheet. Outer holes are where bolts anchor top plate to anchor locker (via large washers overlapping flange in anchor locker).

Exterior view: Empty bolt holes show where bolts and 1" washers (also pictured) attach windlass mounting plate to anchor locker.

Last edited: