Thanks all.

The bilge pump is at the exact bottom of the bilge. There's no way to change the characteristics of the bilge. It's a sump. Deep. Bristol owners will know it.

Bristol installed the sump (bilge) pump and check valve. It's original equipment. There has to be a check valve. Otherwise, the water in the portion of the line lower than the top loop will rush back into the sump, which it's doing now due to (apparently) a failed check valve.

There is no way to keep the sump completely dry. The shaft packing flow ends up there, and the ice box drains into it. There is always a half inch of water in there. There is no place for another, smaller pump at the bottom. There's already the sump pump at the bottom. There's nothing wrong with the float switch.

It has worked well for 29 years. The check valve is well away from the pump, near the top loop. No air issues, no pumping issues, nothing that needs any attention, until recently.

The question was never whether or not the check valve should be there. The question was why is it no longer performing. Someone said maybe to grease the interior, another said just get a new one. I'll try those remedies in that order.

Thanks again.

Form what you are saying that statement is confusing and makes little sense in the realm of the discussion of back flow..

If the check valve is "near the top loop" then what is in the hose on the bilge side will eventually drain back anyway and you are only talking about a 1' or so of water in what is likely a 3/4" hose that is making this difference???

Replace the check valve if you want, as they are not very reliable on a bilge system anyway. They are also quite in-expensive.

Check valves on centrifugal pumps are perhaps my number one cause of killed/destroyed battery banks. Failed or stuck float switches are probably #2 and parasitic loads & battery switches left on #3....

With a leaking stuffing box you could not pay me to install a check valve on our boat, but as Stu always says

"your boat your choice".

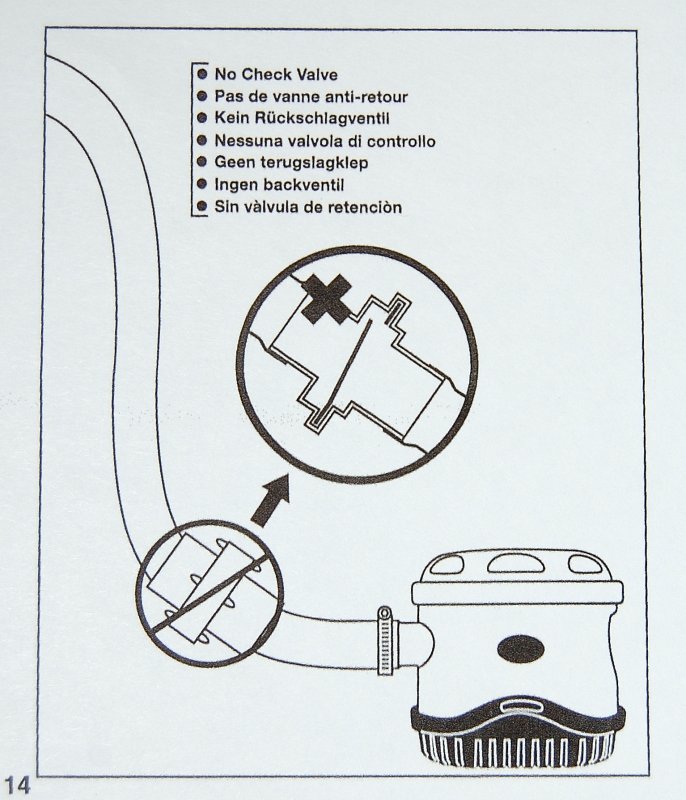

All we can do is try to give you the accurate information direct from the manufacturer of the pump. Just because Bristol ignored proper installation practices does not mean it should or has to stay that way. Many builders have chosen to ignore proper installation procedures of centrifugal pumps in order to save a buck..

Cape Dory has a similar sump on many of their boats and they used a diaphragm pump to solve the problem. Our CS also shipped with a diaphragm pump. Different builders try to save money in different ways, and a diaphragm pump is more costly.

If you must install a check valve I would advise a small hole in the bottom of the hose right before the check valve and the check valve located closer to the pump.. This will allow the pump to purge the air and make the check valve more reliable and less prone to causing the pump to cavitate, fail to evacuate the bilge water and kill the battery bank... They have a very nasty habit of sticking closed and also draining back, as you've found... This hole in the hose is a Band-Aid to a Band-Aid however.....

Even as a kid working in boat yards customers would come in with dead batteries and we'd charge them up only to find the bilge pump stuck on because the check valve was stuck closed. Many a cabin sole or worse was ruined and many battery banks were not salvageable.

The owner of the yard would gruffly say

"Kid go yank that god damn check valve and send them on their way." This is a guy who never even set foot on the boat but could diagnose it from a mile away. Never once did I go down to the boat and not find a check valve causing the issue.. On occasion they would have to swap out the pump for a diaphragm, due to back flow, but in most situations the back flow would not cause cycling. Back then the float switches had mercury and were MUCH more reliable so it was almost always the check valve... This was in the early 80's...... The problem is not new......