After paying almost $400 to have 2 chainplates made I decided I was doing the other 4 myself. I ordered 6 feet of 316L from www.onlinemetals.com for $76.98. That price included the shipping.

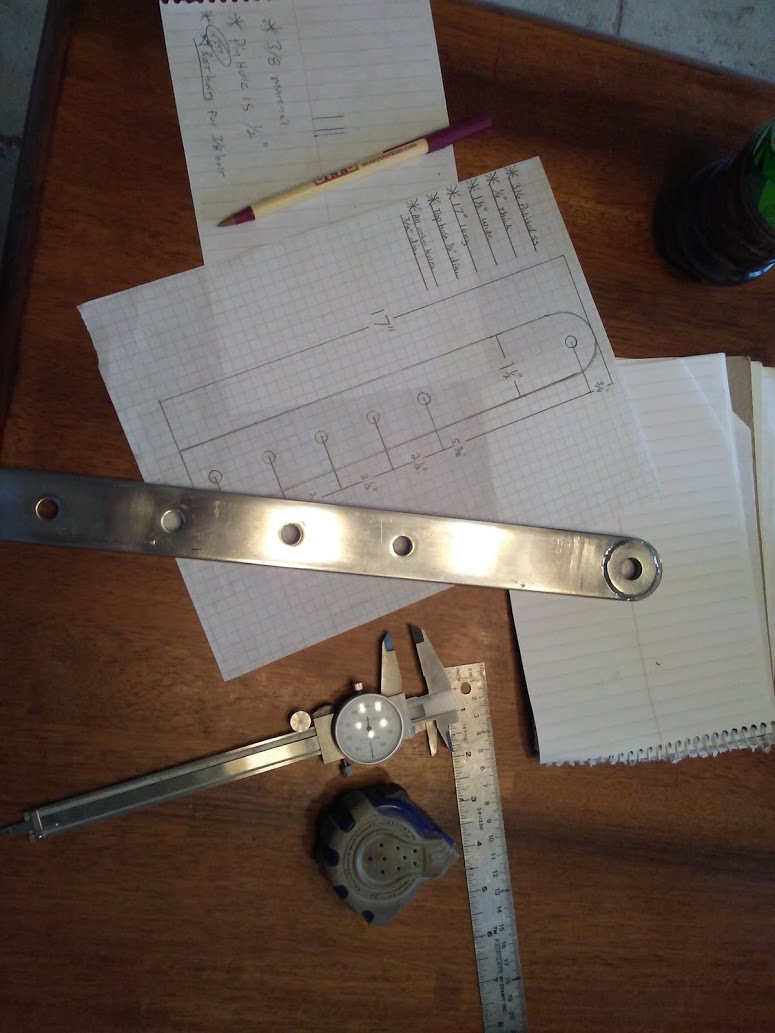

Careful measurements of the old chainplates were taken.

The metal was cut to size and the tops were rounded with a flap disc on a grinder. I was actually surprised how well it worked using a flap disc.

The cut to size pieces were then marked for drilling.

They were drilled (slowly) on a drill press using carbide bits and cutting oil.

After all the holes were drilled the process of polishing began. I started with 80 grit flap discs on a grinder to remove the mill scale then moved on to a 120 grit flap disc. I couldn't find any flap discs finer than 120 grit so the next step was done with 220 on a random orbital sander then 320 then by hand using progressively finer grits wet sanding through 2200. A final polishing was done using barkeepers friend powder mixed with water to a paste consistency on a microfiber rag. The old backing plates were still serviceable so they were polished and reused.

Careful measurements of the old chainplates were taken.

The metal was cut to size and the tops were rounded with a flap disc on a grinder. I was actually surprised how well it worked using a flap disc.

The cut to size pieces were then marked for drilling.

They were drilled (slowly) on a drill press using carbide bits and cutting oil.

After all the holes were drilled the process of polishing began. I started with 80 grit flap discs on a grinder to remove the mill scale then moved on to a 120 grit flap disc. I couldn't find any flap discs finer than 120 grit so the next step was done with 220 on a random orbital sander then 320 then by hand using progressively finer grits wet sanding through 2200. A final polishing was done using barkeepers friend powder mixed with water to a paste consistency on a microfiber rag. The old backing plates were still serviceable so they were polished and reused.