I have three brands of back up belts, Napa Premium, Dayco Top Cog and Advance 15430. The Napa Premium is notched on the inside, the other two on the outside. Which is better?You should always use a grip notched belt especially when doing around a small pulley such as an alternator.

A notched belt has grooves or notches that run perpendicular to the belt's length, which reduces the bending resistance of the belt. Notched belts can use the same pulleys as cross-section standard V-belts. They run cooler, last longer, and are about 2% more efficient than standard V-belts.

BELT DUST

- Thread starter twodzusfittings

- Start date

The Napa premium notched on the inside. The notches allow the belt to go around a small pulley without compressing the belt allowing reduced heat ,dust and longer lifeI have three brands of back up belts, Napa Premium, Dayco Top Cog and Advance 15430. The Napa Premium is notched on the inside, the other two on the outside. Which is better?

Aw crap@ Ralph Johnstone: Correction, that would be three finger pete. Thats a thumbs up!!!!!

Doesn't have the alliteration to it but it is correct:

I did mine that way…carefully holding some sandpaper folded to clean up t he pulleys. OSHA would certainly want a guard or something ;-)

You can certainly do it with the engine off, sand down a little area, rotate the pulley, sand a little more, rotate the pulley, and so on…tedious .

Running the engine and sanding them down is certainly faster…but as my dad used to say, “ Haste makes waste“, or in this case, maybe missing fingers.

Greg

You can certainly do it with the engine off, sand down a little area, rotate the pulley, sand a little more, rotate the pulley, and so on…tedious .

Running the engine and sanding them down is certainly faster…but as my dad used to say, “ Haste makes waste“, or in this case, maybe missing fingers.

Greg

Perhaps because you didn't read the link previously posted in this thread...?Awhhhh Gee. A professional trick... "Why didn't I think of that.... ?"

Marine Alternator Installation - Tips & Tricks - Marine How To

A Fresh New Alternator For many boat owners the task of upgrading their engines alternator can be intimidating. It does not have to be, and this article will help you understand how to do this job correctly. It includes numerous professional

marinehowto.com

The drill is always moving around the crank pulley and is not just staying gin one place...After a six hour trip which ended up taking eight, there is only a very fine dusting. This is after correcting the The dust is also much much finer. I'm getting closer. (Mine used to look like Main Sail's picture)

I get the method in the picture with the drill brush and yes it is much safer. How ever when you do it my method, WHICH I HAVE SAID DO NOT DO, the abrasion is a lot smoother as it works like a lathe. If using the method in the picture and turn it a smidgeon at a time to use the drill wire brush, flat spots will happen and in a random pattern.

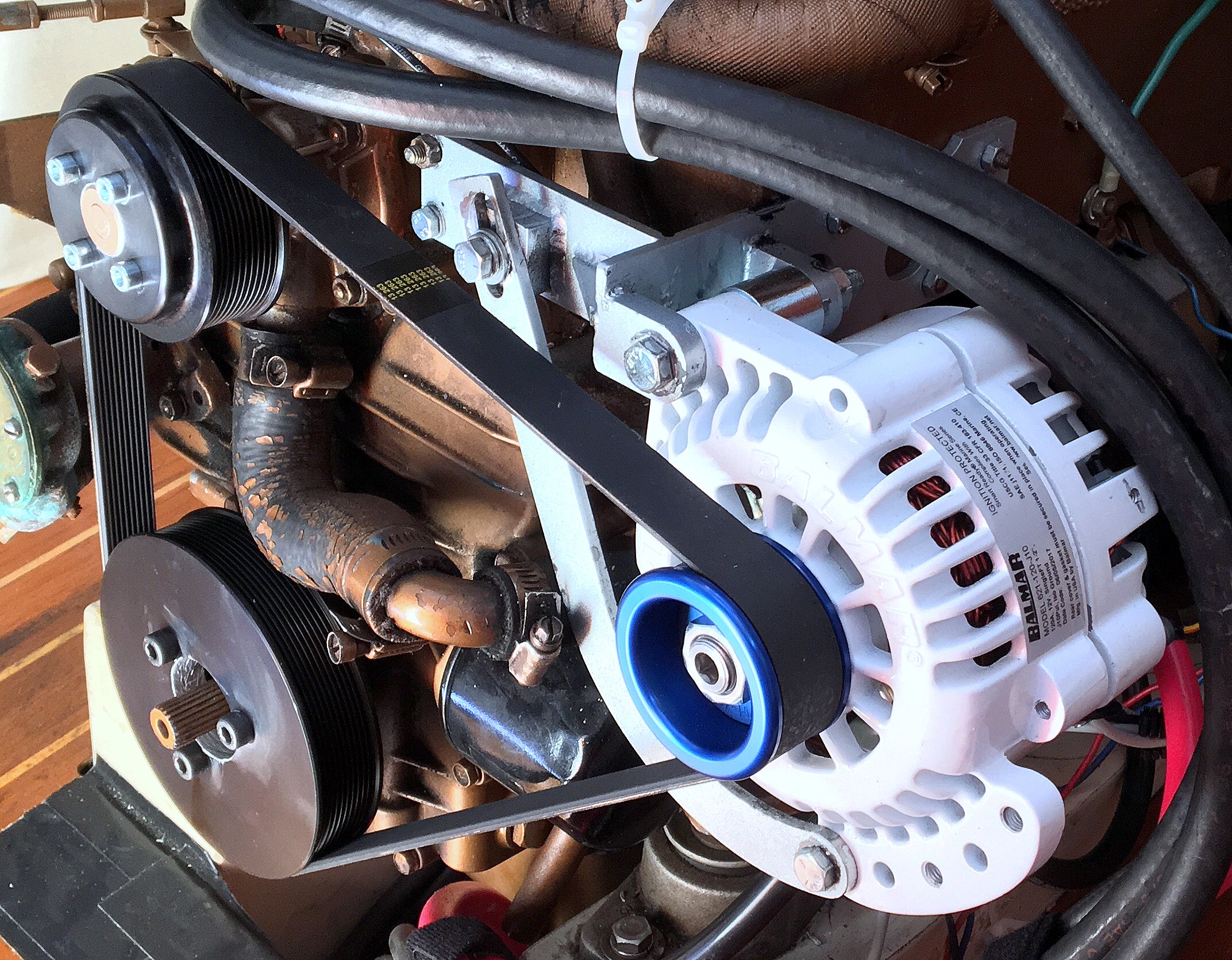

Rid yourself of belt dust completely and improve alternator efficiency, convert to a serpentine belt and pulleys, dust gone.....

I find this thread very disturbing starting with post #18 and suggest the moderators remove it from that position. Having been associated with factories and machine shops my entire career the suggestion to put your fingers into rotating machinery is totally unacceptable. This violates OSHA regulations and is a severe hazard. I've seen my share of injuries and fatalities for Darwin Award recipients through the years. We should be promoting safe practices on this site, not one of the most egregious violations of safety protocols possible. MaineSail has considered the risks involved and developed a process that acceptably minimizes risk. I suggest we all heed his advice.

The brush should cause the pulley to spin. If not, it would be easy enough to put a 3/8 drive socket adaptor in your drill and use the drill on the nut that holds the pulley in place. I'd probably use two drills, one to spin the pulley, and the other to run the wire brush or flap wheel. For the crank pulley, just run the engine without the belts. under no load at idle, you'll have plenty of time to run it before it overheats.... If using the method in the picture and turn it a smidgeon at a time to use the drill wire brush, flat spots will happen and in a random pattern.

I could not agree more. In the mid 70's I took my Porsche 911 to a dealer in Frankfurt (Germany). The engine was running a little rich as I recall. The service advisor came out and bent over the engine. He had a tie on and he damn near got choked to death as I saw the tie catch (but only briefly) the moving belt. The engine was "only" idling but the torque from 175 HP could have strangled him. Her was very, very lucky.I find this thread very disturbing starting with post #18 and suggest the moderators remove it from that position. Having been associated with factories and machine shops my entire career the suggestion to put your fingers into rotating machinery is totally unacceptable. This violates OSHA regulations and is a severe hazard. I've seen my share of injuries and fatalities for Darwin Award recipients through the years. We should be promoting safe practices on this site, not one of the most egregious violations of safety protocols possible. MaineSail has considered the risks involved and developed a process that acceptably minimizes risk. I suggest we all heed his advice.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,875