Note: I broke this topic out of the "Multiple House Banks vs. One" thread because it's important and deserved it's own thread..

What About Intrabank Bank Failures?

An intrabank battery failure can happen in a series-bank, 6V series wired to 6V = 12V. It can also happen in a parallel bank or in a stand alone starting battery. Internal battery failures can sometimes happen as small shorts though a separator but often result as an internally shorted cell when a chunk of plate breaks off and shorts against another one due to age and grid/plate eorrosion. When a 12V battery fails internally it often now becomes a 10V bank as opposed to a 12V bank. What happens when you slap a 10V battery in series or parallel?

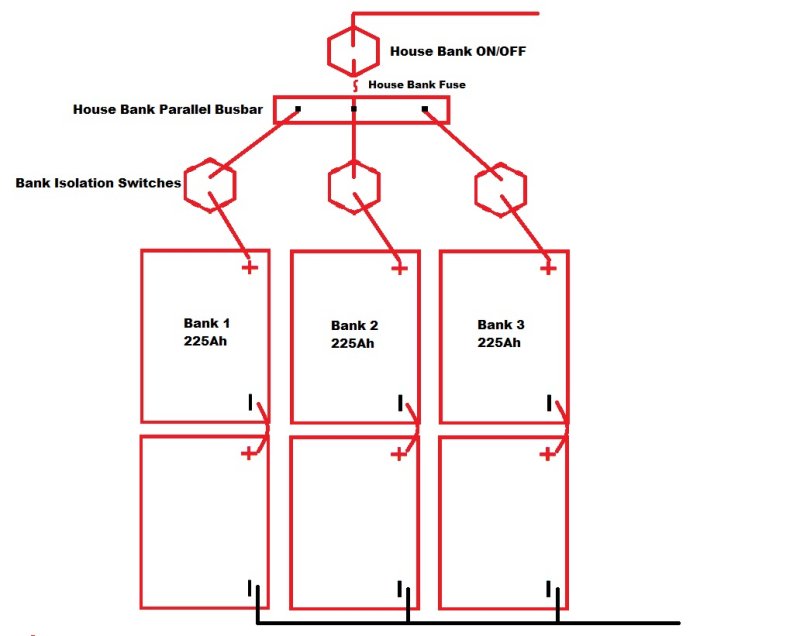

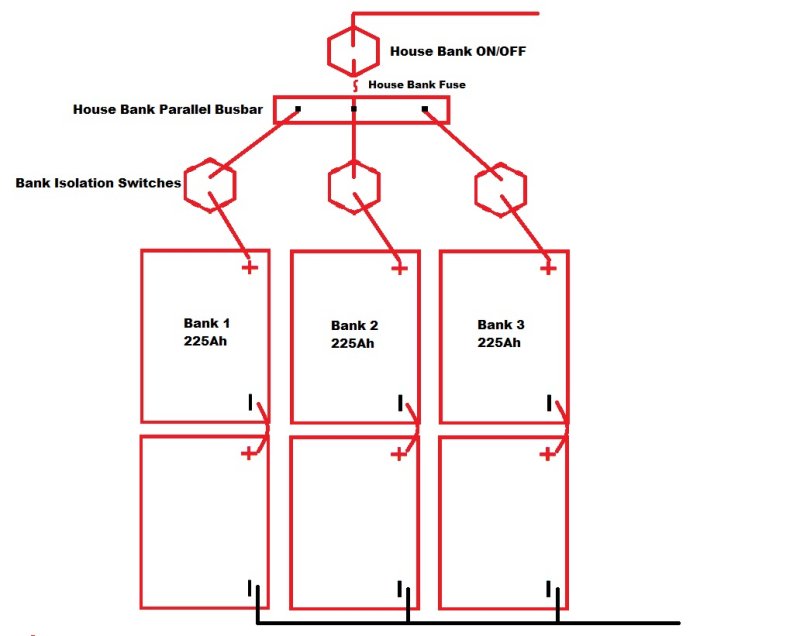

The ultimate best course of action, if you really want to, is a house bank wired per the below diagram. Of course all these switches and the busbar etc. get costly.. A few seconds with a 5/16" or 3/8" wrench and your batteries are now isolated.

Most intrabank failures I have come across tend to happen when no one is even on the boat and while it sits dockside and charging. Isolation switches can't work if there is no human to switch them.

In this diagram only the house bank ON/OFF switch is visible to vessel occupants. The isolation switches & busbar are mounted inches from the battery bank with the main fuse just off the busbar. The isolation switches are only used when physically working on the bank or there is a bank failure.

How can I minimize the risk of failure?

#1 Start with a bank of batteries that are from the same date code and preferably lot #. They should be same model, Ah capacity and brand.

#2 When you can fit them, purchase and use "deep cycle" 12V or 6V golf cart or better industrial grade batteries. If possible avoid "automotive cased" batteries such as Group 24, 27 & 31. The highest internal failure rates I see are in Groups 24, 27, 31, 4D and 8D flooded batteries.

#3 Avoid buying battery inventory that sits. Buy batteries through local battery wholesalers who supply industry and small mom and pop repair facilities. Most metro areas have one. Here in Portland I have two battery distributors within a 25 mile radius.

#4 At least bi yearly, for a parallel bank, un-wire and isolate the batteries and compare the total parallel wired bank voltage to the stand alone open circuit voltage of the individual batteries after 24 hours rest. Any batteries, previously in parallel, with a voltage of more than 0.05V outside of the others should be further examined or tested. A bank that has been contiguously wired in parallel should have all voltages within 0.01 to 0.04V after a 24 hours isolated resting period. If the batteries are flooded cell you can check specific gravity.

#5 All dock-side use battery chargers should have an on battery temperature sensor.

#6 Conduct yearly Ah capacity tests. This is as easy as applying a load of;

Ah Capacity ÷ 20 = Applied Discharge Load

A 100Ah battery would get a 5A load until the battery voltage hits 10.5V. Try to rig a system that lets you adjust the load as the voltage decays to keep it steady. A bank of light bulbs or resistor works or even a PWM 12V dimmer can work to keep the load as close to C÷20 as possible. Recharge immediately after hitting 10.5V.

Start a count down timer (there are free apps on your phone for this) when you turn the load on and note the time the battery ran for and remained above 10.5V. For example a 100Ah battery that ran for 16 hours at 5A is delivering 80% of its 20 hour Ah capacity rating.

Conduct the test with the battery temp between about 74F and 80F or the capacity will be off a bit. Any battery falling below 80% of its rated capacity is getting into the "time to think about new batteries" zone.. For coastal cruising as low as 65-70% with AGM or GEL can be fairly safe but if going off shore you really don't want them to drop much below 75-80% of rated capacity. Below 80% is where I regularly start to see trouble occurring.

Impedance testers such as Midtronics, SPX, Argus (now defunct) etc., really don't tell us much about state of health, as a house bank, and really nothing at all about Ah capacity, but if you start with a baseline, when new, they can tell you a little bit of a story/history. They are better than nothing but really only work to tell us about impulse or cranking current.

#7 Use proper charging voltages per battery manufacturers suggestions. If they tell you that absorption should be 14.8V then it should be 14.8V. If your charger is incompatible with your batteries, buy a new one. Sadly there is a metric $hit ton of horrible battery chargers out there doing nothing to help your batteries stay healthy.

#8 Leave a bit of space around each battery for cooling. A typical battery box tends to do this.

#9 Pay attention to your banks performance and get to know the voltage behavior intimately. For example; if you have been over-nighting and you regularly wake up to see 12.35V in the morning and now, with the same loads & charging practices, you're only seeing 12.0V, stop and test your batteries. Every boat with a house bank should have an accurate volt meter as a bare minimum. This volt meter would preferably a 4 digits or display out to the hundredths position not just the tenths position. A volt meter that can display 12.17V not just 12.2V would be the best choice.

#10 Wire the bank correctly. Where you take your positive and negative connections from matters.

#11 Avoid deep cycles beyond 50% DOD. The shallower the cycles the better bank longevity you will see. Do not regularly discharge your bank below 12.2V even under average house loads.. This should be your recharge point.

#12 Get your batteries recharged to 100% SOC as soon as you can after each deep cycle. PSOC use (partial state of charge cycling use) kills batteries.

#13 If you PSOC cycle your batteries for more than 3-5 days at a time, between 100% SOC recharges, a weekly or bi-monthly short 30 minute equalization would be a great option. Unfortunately most chargers don't have an EQ setting and those that do don't usually allow for a short duration 15.5V to 16V EQ session. The EQ timers in marine chargers are often set at 2-4 hours. In order to circumvent this timer, run an EQ for 20-30 minutes then disconnect the AC power from the charger. Checking the SG for the first few sessions will confirm the duration you'll need.

Once the lead sulfate has hardened and clustered it's dead and no amount of equalization is going to bring it back to active material. If you chronically under charge the batteries, as many marine charge systems do, and let them go too long between EQ's, then all you can do is drop the dead sulfate off the plates to the bottom of the case. Caught soon enough most of the sulfate crystals will still be reconvertable to active material..

Switch Arguments - Multiple House Banks vs. One:

On most cruising boats, where folks are alternating house bank usage, there are almost always more than one battery on each of the two studs of the 1/2/BOTH switch, meaning the switch is still not fully isolating parallel pairs or sets.

If an owners desires switch level battery isolation, hidden ON/OFF switches are the way to go. Hidden switches cut down on confusion for vessel occupants. One main visible switch and the rest hidden out of sight, but in close proximity to the bank is a great option to busting out a wrench..

In a properly wired and installed system, which includes purchasing identical brand and model batteries for a single bank, as one group, with similar date codes & serial numbers, the risk of an internal short is extremely rare.

You really only open or widen the risk pool if you're essentially ignoring your banks aging process. Battery banks used for house banks are almost always pushed far further than they should be, in regards to state of health. Using batteries beyond their safe state of health range creates the most risk.

Which Batteries Fail Most?:

First any lead acid battery can fail internally whether they be GEL, AGM or Flooded!

In my direct field experience the risk of internal shorts is the highest in flooded "automotive cased" batteries such as Group 24, 27 & 31 and 4D and 8D. Starting versions of these flooded group size batteries seem to have a higher failure rate than the "deep cycle" versions especially on power boats that pound.

In my sample size the highest internal failure rates I've seen are in flooded 4D's, then 8D's. I then see Group 24, 27 & 31 flooded batteries as the next highest failure rate. I have also seen failures in true deep cycle golf cart batteries as well as in AGM's. I have yet to see a GEL battery internally short but it is indeed possible.

The failure pictured below happened to one of our own members here, on his Trojan T1275 12V Golf Cart batteries.

Owners Statement:

"The house bank was installed in the spring of 2009 and the boat was in a slip until we left in September of 2011. They failed in March of 2016."

So these were technically 7 year old batteries, age wise, when they died but keep in mind that from September of 2011 to March of 2016 was approx 4.5 years of 24/7/365 live-aboard full time cruising and many, many hundreds of deep cycling events.

The Trojan T1275 12V golf cart batteries are a good quality robustly built deep-cycle battery. Considering the wiring and charging they had, they delivered a very good service life. Unfortunately they had gotten to the point of being beyond safe and one finally let go.

When the owner cruised to Maine last summer, some major changes were made to the wiring and charging system to keep the batteries healthier, for longer, so I suspect the next bank will do even better.

Oh sh!t:

The owner called me and said:

"I felt the bed was warm as I walked by and thought it was the sun. Went back by a while later and noticed it still very warm and lifted the lid to hear and smell the boiling battery."

What to do in a situation like this?

#1 Turn off the battery switch!

#2 Discontinue all charging!

#3 Isolate the batteries from one another ASAP. This can be done by removing either neg side or positive side jumpers, which ever is easier or flipping switches if you've wired the bank for full isolation using "hidden switches".

#4 Switch over to your emergency battery bank! This takes all of two seconds with a proper battery switch configuration. On cruising sailboats there is zero reason to not have a start battery that can do double-duty as a "reserve/emergency bank". By double-duty I mean installing a deep cycle capable battery as the start/reserve bank as opposed to a starting or dual-purpose battery.

Unfortunately the boat above did not have the switching in place to do this. The owner had to physically re-wire the house bank and temporarily use the remaining borderline safe batteries to power the vessel until new batteries could be sources. He used a nut, bolt and some electrical tape to bolt the jumper lugs together thus bypassing the internally shorted battery. I do not recommend this as the primary emergency fix when a simple flip of a switch is a perfectly safe and quick option.

In the event of a battery failure all parallel wired batteries must be physically isolated from one another to prevent a thermal runaway. When one battery fails you should replace the entire bank, not just the bad battery. Only in an absolute emergency, on a boat with no emergency cross-over switch, would you remove or isolate the bad battery and continue on with the remaining batteries which will almost always be in a similar state of health.

Figuring out which is the bad battery, without a temp gun, can be accomplished by measuring the open circuit voltage after a resting period with all batteries isolated from one another.

I suggested to the owner immediately that it was time for new batteries. He replaced the house bank but not the starter... Then this....

But, but, I thought isolated batteries are safe?

No, not really.

As can be seen here the risk of an internal dangerous failure, and intense heat, is not just reserved for house banks in parallel. This excess heat was simply caused by charge sources attempting to charge a now 10V starting battery.

This text one one of the reasons why I can say the argument of isolation switches, and multiple house banks, is simply a low value argument. Sure if you've got the dough wire in isolation switches for each 12V battery in a bank, but what if you're not there when the failure happens? The vast majority of failures I have found have occurred when the vessel has been unattended.

Explosions?

Catastrophic internal shorts that lead to thermal runaway resulting and battery explosions are extremely rare. Most internal shorts start out slow with an increased self discharge rate and one battery always seeming warmer than the others. Eventually the house bank is continually discharging and the charger remains in absorption and you smell battery gassing.

Most battery explosions have nothing to do with an internal short/failure. They most often occur due to incorrect charging & non-compliance with ABYC safety standards for battery ventilation. The cause is almost always due to non-ignition protected equipment being used in the battery space.

Below is a prime example of where a battery physically exploded. Rare? Certainly! Course this one happened right here in Casco Bay and I was there to photograph the result. This occurred in an aluminum boat. This was the only battery on the vessel and it was being charged, in a seat locker, by a Schumacher automotive battery charger. Yes the dumb, & unsafe for unattended use, automotive charger was in the same locker as the battery and was not ignition protected!

Guess what happened to the aluminum boat when it was full of acid. Yes, even a single lead acid battery charged STUPIDLY can be very dangerous. We don't need 6 or more batteries on parallel, just a dumb land based automotive charger.

As can clearly be seen the risk of failure, thermal runaway or even explosion can occur in single battery banks as well as parallel or series paralleled banks. While there is a slight increase in danger with paralleled batteries, it can be dealt with, via switches, if you feel the need.

Series or Series/Parallel vs. Parallel:

When possible I prefer more batteries in series, such as a 6V series or a 6V series / parallel configuration. This means a system with less batteries in parallel, which is arguably a bit safer. Unfortunately in order to build the Ah capacity necessary on today's cruising boats, at some point, parallel wiring is necessary.

Series batteries can't discharge into one another so a series bank is arguably slightly safer in regards to an intra-bank failure. Series banks however can become out of balance, something the industry gives little discussion time to, and one battery can still be getting over charged while one is getting under charged. We can see what happens when batteries are over-charged in the explosion image above.... Proper commissioning & balancing of series batteries is the correct procedure yet it is far to often overlooked and ignored..

What happened above with the Trojan T1275's is a classic case of grid corrosion/erosion/age/use leading to an internal short. These batteries were simply pushed well beyond where they should have been in terms of SOH.

This image is one reason the automotive cased batteries may suffer what I see as a higher internal failure rate. As can be seen the plates sit very low in the case, unlike golf cart batteries, leaving very little room for shed material to build up. These cells from a G-27 battery, were literally sitting in mushy chunky lead & lead sulfate, that had been shed from the plates.

This battery shorted/failed internally and the owner said it was very "hot to the touch". I cut it open to take a look. If we look at the grid to on the left we can see the cracking and shrinkage of the sponge lead material. This shrinkage is a sign of age and use. This age & use I suspect can cause material to fall out of the grid and drop to the bottom of the case thus creating an internal short between positive & negative plates.

Once you lose a cell the battery is no longer a 12V battery but rather it becomes a 10V battery. Lose two cells and it becomes an 8V battery. The batteries in parallel with it will attempt to charge the bad battery to become at parity with their voltage level. This creates heat in the bad battery, and in rare cases, can create a dangerous thermal run away event.

In most cases it just means heat and gassing and a discharged house bank. This is why, on a good cruising boat DC foundation design, we have a second reserve/start bank that can double as temporary house & starting use via cross over & house bank isolation switching.

In most cases, with an internal short, the rest of the bank is simply discharged by the bad battery and there is no dangerous level of thermal runaway, but it can potentially happen, as has been seen.

When you add in a high amperage inverter/charger is where the risk really ramps up. We are now feeding five 12V batteries into a single 10V battery plus a 100A to 150A charger on top of that.....

What About Explosions?

Catastrophic internal shorts that lead to thermal runaway resulting and battery explosions are extremely rare. Most internal shorts start out slow with an increased self discharge rate and one battery always seeming warmer than the others. Eventually the house bank is continually discharging and the charger remains in absorption and you smell battery gassing.

Most battery explosions have nothing to do with an internal short/failure, but they can due to excess gassing. Explosions most often occur due to non-compliance with ABYC safety standards for battery compartment ventilation. The cause is almost always due to non-ignition protected equipment being used in or near the battery space.

Charge Source Industry & ABYC Failings:

In a perfect world all marine battery charge sources would have the ability to wire in as many temp sensors as you have batteries, and any one of the sensors could then shut the charger down. This should be standard operating procedure for the marine, off-grid and RV market. Sadly it is not.

Unfortunately we don't live in a perfect world and the marine charge equipment market has failed us on the safety front. One can easily argue the ABYC has also let us down too. Seriously, why is one temp sensor standard practice and "acceptable" on a vessel with ten batteries..?? The simple answer is that it should not be acceptable.

The technology to do this is easy, industry gold standards sensors such as the LM335 temp sensors are 96¢ each. Add a bit of wire and a terminal with some epoxy and charge $40.00 each and they are actually making money, in a big way.

It would be nice, even if it was an add on option, but as of yet not one single charger manufacturer I know of offers multiple battery temp sensors. Silly and simply INSANE. The Balmar MC-614 alternator regulator can monitor two batteries, a step in the right direction, but that is still not enough on boats with multiple battery, battery banks..

Dockside Charging Dangers:

When leaving a vessel unattended it's best to use the smallest charger possible to maintain the bank and shore side loads. In my opinion, one of the poorest practices I see at docks, is using 100A - 150A + inverter chargers as your maintenance charger. Having a 150A of current potential, in order to supply mA of float charge current, when you're there, is not my bag of tea.

I will go so far is to call the practice CRAZY but, as owners and an industry, we've become complacent. Because failures are rare, we ignore the importance of the dangers that can happen when leaving LARGE CURRENT charge sources to baby sit battery banks requiring just mA's of current to satisfy them..

Sure, when off shore running a gen set to quickly put some energy back into the bank, a 100A to 150A inverter/charger is a God send but, to leave a 100A to 150A charger sitting there to maintain mA level currents is just foolish. If a failure happens it can quickly become very dangerous with a large current charge source connected.

Why are large inverter/ chargers a poor practice for float charging?

With a 10A charger, 5A may be going to DC system loads, and only 5A to the battery. If you develop a shorted battery, that may now be a 10V battery, that battery will begin sucking charge from the other 12V batteries. The differential voltage is still usually 1.8V or less. We can't really develop a ton of current, leading to heat and thermal runaway, with a low differential voltage. When you stack a small 5A charge current on top if this, it does not create a real huge difference in the voltage potential.

However add a 100A to 150A charger on top of multiple other 12V batteries, which are also feeding the shorted one, and you've just created a really dangerous situation especially when the ONE temps sensor is on the WRONG battery.

That dude Murphy always dictates that ONE single battery temp sensor, for the 100A to 150A inverter/charger, is never going to be on the shorted battery.

This is the failing of the charger & safety standards industry that I am referring to.

Internal shorts most often start out small, and present themselves in faster than usual voltage decay & self discharge, when not charging. When charging, they present themselves in a manner in which the charge current no longer drops as low as it once did. For example, with no loads on, with a typical float voltage, your bank may have normally been accepting 0.2A of charge current at 13.4V and now it never drops below 9A.. This is a red flag..

If you pay close attention to your ammeter and battery voltage, and using an accurate voltmeter that reads to the hundredths (12.72V) not just tenths (12.7V) you can learn to spot any irregularities in the bank voltage and full charge amperage performance.

Large chargers, left unattended, are simply going to remain a dangerous practice until charger makers begin to provide us with the ability to sense the temperature of every battery on board...

You as a human are still the best defense against internal battery failures, if you pay attention to your bank. I rarely see batteries rapidly & suddenly declie, though I have seen some. Learn your system and its typical behaviors and you'll be better attuned to spotting irregularities in bank behavior..

Course if you are on-board, as our forum member above was, your own senses can help alert you to danger..

What About Intrabank Bank Failures?

An intrabank battery failure can happen in a series-bank, 6V series wired to 6V = 12V. It can also happen in a parallel bank or in a stand alone starting battery. Internal battery failures can sometimes happen as small shorts though a separator but often result as an internally shorted cell when a chunk of plate breaks off and shorts against another one due to age and grid/plate eorrosion. When a 12V battery fails internally it often now becomes a 10V bank as opposed to a 12V bank. What happens when you slap a 10V battery in series or parallel?

- In a series bank, if charging, the batteries wind up getting over charged. If not charging the battery voltage is just lower, say 10.2V vs. 12.7V.

- In a parallel bank the other batteries are now discharging into the 10V battery trying to bring it back to 12V. If we stack charging on top of this, especially high amperage charging, the danger level increases.

The ultimate best course of action, if you really want to, is a house bank wired per the below diagram. Of course all these switches and the busbar etc. get costly.. A few seconds with a 5/16" or 3/8" wrench and your batteries are now isolated.

Most intrabank failures I have come across tend to happen when no one is even on the boat and while it sits dockside and charging. Isolation switches can't work if there is no human to switch them.

In this diagram only the house bank ON/OFF switch is visible to vessel occupants. The isolation switches & busbar are mounted inches from the battery bank with the main fuse just off the busbar. The isolation switches are only used when physically working on the bank or there is a bank failure.

How can I minimize the risk of failure?

#1 Start with a bank of batteries that are from the same date code and preferably lot #. They should be same model, Ah capacity and brand.

#2 When you can fit them, purchase and use "deep cycle" 12V or 6V golf cart or better industrial grade batteries. If possible avoid "automotive cased" batteries such as Group 24, 27 & 31. The highest internal failure rates I see are in Groups 24, 27, 31, 4D and 8D flooded batteries.

#3 Avoid buying battery inventory that sits. Buy batteries through local battery wholesalers who supply industry and small mom and pop repair facilities. Most metro areas have one. Here in Portland I have two battery distributors within a 25 mile radius.

#4 At least bi yearly, for a parallel bank, un-wire and isolate the batteries and compare the total parallel wired bank voltage to the stand alone open circuit voltage of the individual batteries after 24 hours rest. Any batteries, previously in parallel, with a voltage of more than 0.05V outside of the others should be further examined or tested. A bank that has been contiguously wired in parallel should have all voltages within 0.01 to 0.04V after a 24 hours isolated resting period. If the batteries are flooded cell you can check specific gravity.

#5 All dock-side use battery chargers should have an on battery temperature sensor.

#6 Conduct yearly Ah capacity tests. This is as easy as applying a load of;

Ah Capacity ÷ 20 = Applied Discharge Load

A 100Ah battery would get a 5A load until the battery voltage hits 10.5V. Try to rig a system that lets you adjust the load as the voltage decays to keep it steady. A bank of light bulbs or resistor works or even a PWM 12V dimmer can work to keep the load as close to C÷20 as possible. Recharge immediately after hitting 10.5V.

Start a count down timer (there are free apps on your phone for this) when you turn the load on and note the time the battery ran for and remained above 10.5V. For example a 100Ah battery that ran for 16 hours at 5A is delivering 80% of its 20 hour Ah capacity rating.

Conduct the test with the battery temp between about 74F and 80F or the capacity will be off a bit. Any battery falling below 80% of its rated capacity is getting into the "time to think about new batteries" zone.. For coastal cruising as low as 65-70% with AGM or GEL can be fairly safe but if going off shore you really don't want them to drop much below 75-80% of rated capacity. Below 80% is where I regularly start to see trouble occurring.

Impedance testers such as Midtronics, SPX, Argus (now defunct) etc., really don't tell us much about state of health, as a house bank, and really nothing at all about Ah capacity, but if you start with a baseline, when new, they can tell you a little bit of a story/history. They are better than nothing but really only work to tell us about impulse or cranking current.

#7 Use proper charging voltages per battery manufacturers suggestions. If they tell you that absorption should be 14.8V then it should be 14.8V. If your charger is incompatible with your batteries, buy a new one. Sadly there is a metric $hit ton of horrible battery chargers out there doing nothing to help your batteries stay healthy.

#8 Leave a bit of space around each battery for cooling. A typical battery box tends to do this.

#9 Pay attention to your banks performance and get to know the voltage behavior intimately. For example; if you have been over-nighting and you regularly wake up to see 12.35V in the morning and now, with the same loads & charging practices, you're only seeing 12.0V, stop and test your batteries. Every boat with a house bank should have an accurate volt meter as a bare minimum. This volt meter would preferably a 4 digits or display out to the hundredths position not just the tenths position. A volt meter that can display 12.17V not just 12.2V would be the best choice.

#10 Wire the bank correctly. Where you take your positive and negative connections from matters.

#11 Avoid deep cycles beyond 50% DOD. The shallower the cycles the better bank longevity you will see. Do not regularly discharge your bank below 12.2V even under average house loads.. This should be your recharge point.

#12 Get your batteries recharged to 100% SOC as soon as you can after each deep cycle. PSOC use (partial state of charge cycling use) kills batteries.

#13 If you PSOC cycle your batteries for more than 3-5 days at a time, between 100% SOC recharges, a weekly or bi-monthly short 30 minute equalization would be a great option. Unfortunately most chargers don't have an EQ setting and those that do don't usually allow for a short duration 15.5V to 16V EQ session. The EQ timers in marine chargers are often set at 2-4 hours. In order to circumvent this timer, run an EQ for 20-30 minutes then disconnect the AC power from the charger. Checking the SG for the first few sessions will confirm the duration you'll need.

Once the lead sulfate has hardened and clustered it's dead and no amount of equalization is going to bring it back to active material. If you chronically under charge the batteries, as many marine charge systems do, and let them go too long between EQ's, then all you can do is drop the dead sulfate off the plates to the bottom of the case. Caught soon enough most of the sulfate crystals will still be reconvertable to active material..

Switch Arguments - Multiple House Banks vs. One:

On most cruising boats, where folks are alternating house bank usage, there are almost always more than one battery on each of the two studs of the 1/2/BOTH switch, meaning the switch is still not fully isolating parallel pairs or sets.

If an owners desires switch level battery isolation, hidden ON/OFF switches are the way to go. Hidden switches cut down on confusion for vessel occupants. One main visible switch and the rest hidden out of sight, but in close proximity to the bank is a great option to busting out a wrench..

In a properly wired and installed system, which includes purchasing identical brand and model batteries for a single bank, as one group, with similar date codes & serial numbers, the risk of an internal short is extremely rare.

You really only open or widen the risk pool if you're essentially ignoring your banks aging process. Battery banks used for house banks are almost always pushed far further than they should be, in regards to state of health. Using batteries beyond their safe state of health range creates the most risk.

Which Batteries Fail Most?:

First any lead acid battery can fail internally whether they be GEL, AGM or Flooded!

In my direct field experience the risk of internal shorts is the highest in flooded "automotive cased" batteries such as Group 24, 27 & 31 and 4D and 8D. Starting versions of these flooded group size batteries seem to have a higher failure rate than the "deep cycle" versions especially on power boats that pound.

In my sample size the highest internal failure rates I've seen are in flooded 4D's, then 8D's. I then see Group 24, 27 & 31 flooded batteries as the next highest failure rate. I have also seen failures in true deep cycle golf cart batteries as well as in AGM's. I have yet to see a GEL battery internally short but it is indeed possible.

The failure pictured below happened to one of our own members here, on his Trojan T1275 12V Golf Cart batteries.

Owners Statement:

"The house bank was installed in the spring of 2009 and the boat was in a slip until we left in September of 2011. They failed in March of 2016."

So these were technically 7 year old batteries, age wise, when they died but keep in mind that from September of 2011 to March of 2016 was approx 4.5 years of 24/7/365 live-aboard full time cruising and many, many hundreds of deep cycling events.

The Trojan T1275 12V golf cart batteries are a good quality robustly built deep-cycle battery. Considering the wiring and charging they had, they delivered a very good service life. Unfortunately they had gotten to the point of being beyond safe and one finally let go.

When the owner cruised to Maine last summer, some major changes were made to the wiring and charging system to keep the batteries healthier, for longer, so I suspect the next bank will do even better.

Oh sh!t:

The owner called me and said:

"I felt the bed was warm as I walked by and thought it was the sun. Went back by a while later and noticed it still very warm and lifted the lid to hear and smell the boiling battery."

What to do in a situation like this?

#1 Turn off the battery switch!

#2 Discontinue all charging!

#3 Isolate the batteries from one another ASAP. This can be done by removing either neg side or positive side jumpers, which ever is easier or flipping switches if you've wired the bank for full isolation using "hidden switches".

#4 Switch over to your emergency battery bank! This takes all of two seconds with a proper battery switch configuration. On cruising sailboats there is zero reason to not have a start battery that can do double-duty as a "reserve/emergency bank". By double-duty I mean installing a deep cycle capable battery as the start/reserve bank as opposed to a starting or dual-purpose battery.

Unfortunately the boat above did not have the switching in place to do this. The owner had to physically re-wire the house bank and temporarily use the remaining borderline safe batteries to power the vessel until new batteries could be sources. He used a nut, bolt and some electrical tape to bolt the jumper lugs together thus bypassing the internally shorted battery. I do not recommend this as the primary emergency fix when a simple flip of a switch is a perfectly safe and quick option.

In the event of a battery failure all parallel wired batteries must be physically isolated from one another to prevent a thermal runaway. When one battery fails you should replace the entire bank, not just the bad battery. Only in an absolute emergency, on a boat with no emergency cross-over switch, would you remove or isolate the bad battery and continue on with the remaining batteries which will almost always be in a similar state of health.

Figuring out which is the bad battery, without a temp gun, can be accomplished by measuring the open circuit voltage after a resting period with all batteries isolated from one another.

I suggested to the owner immediately that it was time for new batteries. He replaced the house bank but not the starter... Then this....

But, but, I thought isolated batteries are safe?

No, not really.

As can be seen here the risk of an internal dangerous failure, and intense heat, is not just reserved for house banks in parallel. This excess heat was simply caused by charge sources attempting to charge a now 10V starting battery.

This text one one of the reasons why I can say the argument of isolation switches, and multiple house banks, is simply a low value argument. Sure if you've got the dough wire in isolation switches for each 12V battery in a bank, but what if you're not there when the failure happens? The vast majority of failures I have found have occurred when the vessel has been unattended.

Explosions?

Catastrophic internal shorts that lead to thermal runaway resulting and battery explosions are extremely rare. Most internal shorts start out slow with an increased self discharge rate and one battery always seeming warmer than the others. Eventually the house bank is continually discharging and the charger remains in absorption and you smell battery gassing.

Most battery explosions have nothing to do with an internal short/failure. They most often occur due to incorrect charging & non-compliance with ABYC safety standards for battery ventilation. The cause is almost always due to non-ignition protected equipment being used in the battery space.

Below is a prime example of where a battery physically exploded. Rare? Certainly! Course this one happened right here in Casco Bay and I was there to photograph the result. This occurred in an aluminum boat. This was the only battery on the vessel and it was being charged, in a seat locker, by a Schumacher automotive battery charger. Yes the dumb, & unsafe for unattended use, automotive charger was in the same locker as the battery and was not ignition protected!

Guess what happened to the aluminum boat when it was full of acid. Yes, even a single lead acid battery charged STUPIDLY can be very dangerous. We don't need 6 or more batteries on parallel, just a dumb land based automotive charger.

As can clearly be seen the risk of failure, thermal runaway or even explosion can occur in single battery banks as well as parallel or series paralleled banks. While there is a slight increase in danger with paralleled batteries, it can be dealt with, via switches, if you feel the need.

Series or Series/Parallel vs. Parallel:

When possible I prefer more batteries in series, such as a 6V series or a 6V series / parallel configuration. This means a system with less batteries in parallel, which is arguably a bit safer. Unfortunately in order to build the Ah capacity necessary on today's cruising boats, at some point, parallel wiring is necessary.

Series batteries can't discharge into one another so a series bank is arguably slightly safer in regards to an intra-bank failure. Series banks however can become out of balance, something the industry gives little discussion time to, and one battery can still be getting over charged while one is getting under charged. We can see what happens when batteries are over-charged in the explosion image above.... Proper commissioning & balancing of series batteries is the correct procedure yet it is far to often overlooked and ignored..

What happened above with the Trojan T1275's is a classic case of grid corrosion/erosion/age/use leading to an internal short. These batteries were simply pushed well beyond where they should have been in terms of SOH.

This image is one reason the automotive cased batteries may suffer what I see as a higher internal failure rate. As can be seen the plates sit very low in the case, unlike golf cart batteries, leaving very little room for shed material to build up. These cells from a G-27 battery, were literally sitting in mushy chunky lead & lead sulfate, that had been shed from the plates.

This battery shorted/failed internally and the owner said it was very "hot to the touch". I cut it open to take a look. If we look at the grid to on the left we can see the cracking and shrinkage of the sponge lead material. This shrinkage is a sign of age and use. This age & use I suspect can cause material to fall out of the grid and drop to the bottom of the case thus creating an internal short between positive & negative plates.

Once you lose a cell the battery is no longer a 12V battery but rather it becomes a 10V battery. Lose two cells and it becomes an 8V battery. The batteries in parallel with it will attempt to charge the bad battery to become at parity with their voltage level. This creates heat in the bad battery, and in rare cases, can create a dangerous thermal run away event.

In most cases it just means heat and gassing and a discharged house bank. This is why, on a good cruising boat DC foundation design, we have a second reserve/start bank that can double as temporary house & starting use via cross over & house bank isolation switching.

In most cases, with an internal short, the rest of the bank is simply discharged by the bad battery and there is no dangerous level of thermal runaway, but it can potentially happen, as has been seen.

When you add in a high amperage inverter/charger is where the risk really ramps up. We are now feeding five 12V batteries into a single 10V battery plus a 100A to 150A charger on top of that.....

What About Explosions?

Catastrophic internal shorts that lead to thermal runaway resulting and battery explosions are extremely rare. Most internal shorts start out slow with an increased self discharge rate and one battery always seeming warmer than the others. Eventually the house bank is continually discharging and the charger remains in absorption and you smell battery gassing.

Most battery explosions have nothing to do with an internal short/failure, but they can due to excess gassing. Explosions most often occur due to non-compliance with ABYC safety standards for battery compartment ventilation. The cause is almost always due to non-ignition protected equipment being used in or near the battery space.

Charge Source Industry & ABYC Failings:

In a perfect world all marine battery charge sources would have the ability to wire in as many temp sensors as you have batteries, and any one of the sensors could then shut the charger down. This should be standard operating procedure for the marine, off-grid and RV market. Sadly it is not.

Unfortunately we don't live in a perfect world and the marine charge equipment market has failed us on the safety front. One can easily argue the ABYC has also let us down too. Seriously, why is one temp sensor standard practice and "acceptable" on a vessel with ten batteries..?? The simple answer is that it should not be acceptable.

The technology to do this is easy, industry gold standards sensors such as the LM335 temp sensors are 96¢ each. Add a bit of wire and a terminal with some epoxy and charge $40.00 each and they are actually making money, in a big way.

It would be nice, even if it was an add on option, but as of yet not one single charger manufacturer I know of offers multiple battery temp sensors. Silly and simply INSANE. The Balmar MC-614 alternator regulator can monitor two batteries, a step in the right direction, but that is still not enough on boats with multiple battery, battery banks..

Dockside Charging Dangers:

When leaving a vessel unattended it's best to use the smallest charger possible to maintain the bank and shore side loads. In my opinion, one of the poorest practices I see at docks, is using 100A - 150A + inverter chargers as your maintenance charger. Having a 150A of current potential, in order to supply mA of float charge current, when you're there, is not my bag of tea.

I will go so far is to call the practice CRAZY but, as owners and an industry, we've become complacent. Because failures are rare, we ignore the importance of the dangers that can happen when leaving LARGE CURRENT charge sources to baby sit battery banks requiring just mA's of current to satisfy them..

Sure, when off shore running a gen set to quickly put some energy back into the bank, a 100A to 150A inverter/charger is a God send but, to leave a 100A to 150A charger sitting there to maintain mA level currents is just foolish. If a failure happens it can quickly become very dangerous with a large current charge source connected.

Why are large inverter/ chargers a poor practice for float charging?

With a 10A charger, 5A may be going to DC system loads, and only 5A to the battery. If you develop a shorted battery, that may now be a 10V battery, that battery will begin sucking charge from the other 12V batteries. The differential voltage is still usually 1.8V or less. We can't really develop a ton of current, leading to heat and thermal runaway, with a low differential voltage. When you stack a small 5A charge current on top if this, it does not create a real huge difference in the voltage potential.

However add a 100A to 150A charger on top of multiple other 12V batteries, which are also feeding the shorted one, and you've just created a really dangerous situation especially when the ONE temps sensor is on the WRONG battery.

That dude Murphy always dictates that ONE single battery temp sensor, for the 100A to 150A inverter/charger, is never going to be on the shorted battery.

This is the failing of the charger & safety standards industry that I am referring to.

Internal shorts most often start out small, and present themselves in faster than usual voltage decay & self discharge, when not charging. When charging, they present themselves in a manner in which the charge current no longer drops as low as it once did. For example, with no loads on, with a typical float voltage, your bank may have normally been accepting 0.2A of charge current at 13.4V and now it never drops below 9A.. This is a red flag..

If you pay close attention to your ammeter and battery voltage, and using an accurate voltmeter that reads to the hundredths (12.72V) not just tenths (12.7V) you can learn to spot any irregularities in the bank voltage and full charge amperage performance.

Large chargers, left unattended, are simply going to remain a dangerous practice until charger makers begin to provide us with the ability to sense the temperature of every battery on board...

You as a human are still the best defense against internal battery failures, if you pay attention to your bank. I rarely see batteries rapidly & suddenly declie, though I have seen some. Learn your system and its typical behaviors and you'll be better attuned to spotting irregularities in bank behavior..

Course if you are on-board, as our forum member above was, your own senses can help alert you to danger..