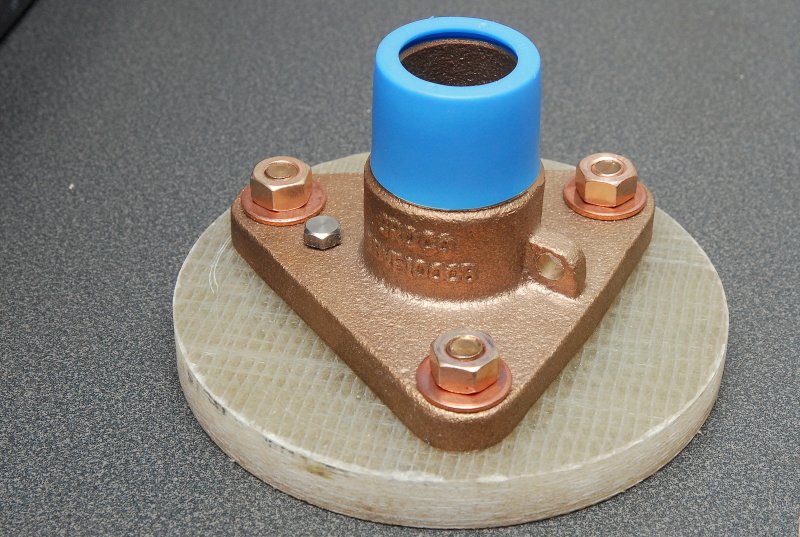

While installing new hoses ,I noticed the original plywood backing for the through hull was rotted .

I cut out a replacement from plywood and was about to coat it in epoxy, when I noticed I had uhmw plastic the same thickness .

I'm wondering if using bed it tape and the UHMW plastic might be a better choice than expoxy soaked plywood .

The plywood lasted 40 plus years.. Thanks

I cut out a replacement from plywood and was about to coat it in epoxy, when I noticed I had uhmw plastic the same thickness .

I'm wondering if using bed it tape and the UHMW plastic might be a better choice than expoxy soaked plywood .

The plywood lasted 40 plus years.. Thanks