Every since we bought our boat I have wished it had bow storage for the anchor and rode. I think the worst part of sailing for me is dragging the anchor, chain, and rode forward and back each time we go to drop the hook. Between narrow sidekicks, the shrouds, and the waves, it is always a accident waiting to happen.

Well I had finally had enough and over the winter started planning on how to get a anchor locker. I had bought three large Old Town hatches from topkayaker.com that I installed in three of our kayaks and thought it was about the right size. After a trail run to see if our anchor would fit, which it did with no problem, I went to order another one. Just my luck, discontinued. After searching for something similar I finally gave up and just stole the hatch out of the spare kayak we keep for guest. I will worry about finding a replacement for it later.

Yesterday I started cutting and making templates. Here is the hatch in the hole

It is a really nice hatch with dual latches and tether for the lid. Before I cut any holes I put it on the ground an jumped up and down on it to make sure it was tough enough. If it was going to break better it break on the floor than the boat.

It is a sealed hatch and I have not had any issues with water leaking in on the kayaks. It is going to be self draining locker so even if a little gets in it will drain out on its own.

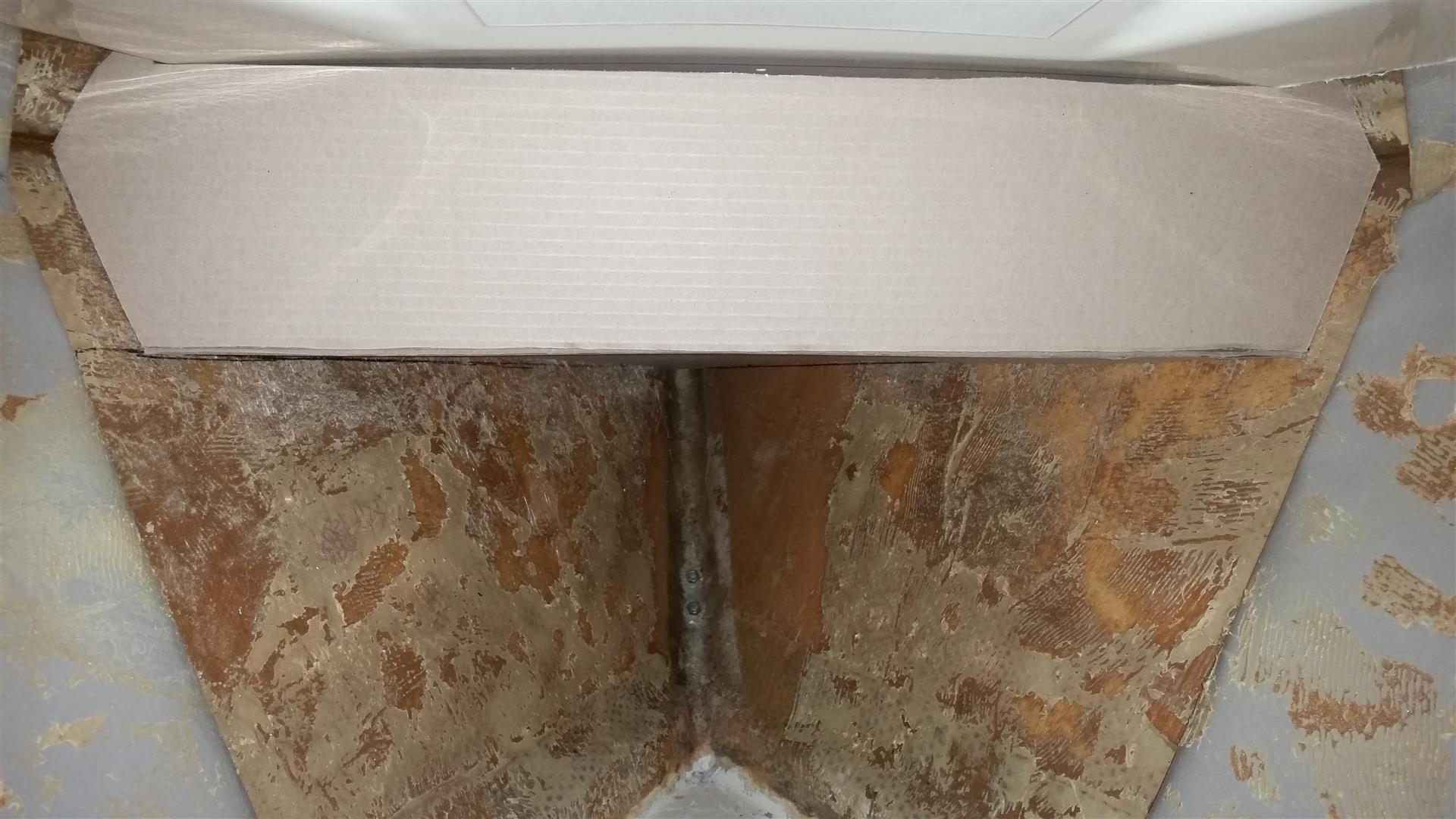

Now time to go inside. I had to peel the carpet back off the walls, and remove the glue first then mark off the level I wanted to floor of the locker well.

I put a 2 inch drop towards the bow so the water will run forward and then out the drain hole. Scraping the glue off was by far the worst part of the job. Lets just say it stuck to the hull better than the carpet.

With the glue scraped away it was time to make a pattern for the bottom and the back of the locker out of cardboard.

Not too bad for the first try. After making a few adjustments and added measurements I cut the pieces out of 1/4" ply. After I fit those pieces I will start glassing them with 6 oz fabric and West systems epoxy that I use on kayaks. Once that is done I can epoxy them into the boat.

Cindy wasn't too sure about this project, probably because she never had to drag the anchor forward to the bow or back. Her big concern was that we would not have room for our feet as she likes sleeping in the V birth. Well we used to have a small 12 volt fan that hung there and it was down 9". The locker extends down 6 inches at the back edge so we actually have more room now. I tried it out and it will work out just fine

The fan never really moved air that well anyway and it was noisy so now I can replace it with a quitter fan and put it someplace better.

I did a test fit with the anchor and it is going to have plenty of room for the anchor we use and I think that the small claw anchor we have might even have enough room to go in there as well.

Either way I am very excited to have a place on the bow to store the anchor and rode. I plan on painting the hatch gray to match the new antiskid paint as I am changing the white to a light gray. I really liked the look of the white when I did it originally last spring but after seeing how dirty it looked after sitting out on the slip after the first week I hated it. Seemed like each time we sailed I was scrubbing the dirt off the decks. Friends of our had gray antiskid and it did not show dirt nearly as bad. Live and learn.

I was happy to see that the deck was cored with 1/4" ply instead of balsa. It was right at a 3/4" thick in that area and is still very strong, as determined from my bounce test. I will post more pics as the project progresses.

Sam

Well I had finally had enough and over the winter started planning on how to get a anchor locker. I had bought three large Old Town hatches from topkayaker.com that I installed in three of our kayaks and thought it was about the right size. After a trail run to see if our anchor would fit, which it did with no problem, I went to order another one. Just my luck, discontinued. After searching for something similar I finally gave up and just stole the hatch out of the spare kayak we keep for guest. I will worry about finding a replacement for it later.

Yesterday I started cutting and making templates. Here is the hatch in the hole

It is a really nice hatch with dual latches and tether for the lid. Before I cut any holes I put it on the ground an jumped up and down on it to make sure it was tough enough. If it was going to break better it break on the floor than the boat.

It is a sealed hatch and I have not had any issues with water leaking in on the kayaks. It is going to be self draining locker so even if a little gets in it will drain out on its own.

Now time to go inside. I had to peel the carpet back off the walls, and remove the glue first then mark off the level I wanted to floor of the locker well.

I put a 2 inch drop towards the bow so the water will run forward and then out the drain hole. Scraping the glue off was by far the worst part of the job. Lets just say it stuck to the hull better than the carpet.

With the glue scraped away it was time to make a pattern for the bottom and the back of the locker out of cardboard.

Not too bad for the first try. After making a few adjustments and added measurements I cut the pieces out of 1/4" ply. After I fit those pieces I will start glassing them with 6 oz fabric and West systems epoxy that I use on kayaks. Once that is done I can epoxy them into the boat.

Cindy wasn't too sure about this project, probably because she never had to drag the anchor forward to the bow or back. Her big concern was that we would not have room for our feet as she likes sleeping in the V birth. Well we used to have a small 12 volt fan that hung there and it was down 9". The locker extends down 6 inches at the back edge so we actually have more room now. I tried it out and it will work out just fine

The fan never really moved air that well anyway and it was noisy so now I can replace it with a quitter fan and put it someplace better.

I did a test fit with the anchor and it is going to have plenty of room for the anchor we use and I think that the small claw anchor we have might even have enough room to go in there as well.

Either way I am very excited to have a place on the bow to store the anchor and rode. I plan on painting the hatch gray to match the new antiskid paint as I am changing the white to a light gray. I really liked the look of the white when I did it originally last spring but after seeing how dirty it looked after sitting out on the slip after the first week I hated it. Seemed like each time we sailed I was scrubbing the dirt off the decks. Friends of our had gray antiskid and it did not show dirt nearly as bad. Live and learn.

I was happy to see that the deck was cored with 1/4" ply instead of balsa. It was right at a 3/4" thick in that area and is still very strong, as determined from my bounce test. I will post more pics as the project progresses.

Sam