Alternator belt tension

- Thread starter Clydo

- Start date

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,802

I’ve been using the 3/8 in estimate or the little less than 90 degree rotation on the longest span technique. It has served adequately.

Then I came across this more specific description from a belt manufacturer.

The most common method for drive tensioning is “force deflection.” A predetermined force is applied to the open span of the belt drive. If the deflection exceeds 1/64 in. for every inch of span length, the drive is tensioned higher. If the deflection is too small, drive tension is excessive, and must be reduced.

Then I came across this more specific description from a belt manufacturer.

The most common method for drive tensioning is “force deflection.” A predetermined force is applied to the open span of the belt drive. If the deflection exceeds 1/64 in. for every inch of span length, the drive is tensioned higher. If the deflection is too small, drive tension is excessive, and must be reduced.

But John, without knowing the force being applied there's no way to use that technique?I’ve been using the 3/8 in estimate or the little less than 90 degree rotation on the longest span technique. It has served adequately.

Then I came across this more specific description from a belt manufacturer.

The most common method for drive tensioning is “force deflection.” A predetermined force is applied to the open span of the belt drive. If the deflection exceeds 1/64 in. for every inch of span length, the drive is tensioned higher. If the deflection is too small, drive tension is excessive, and must be reduced.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,802

So true @marchem

Perhaps only slightly better than:

And then there is this guidance... Again limited on detailed specific tensioning specifics...

How to tension a belt correctly?

Perhaps only slightly better than:

- "Whack the belt with a karate chop, and if it feels firm, the drive is properly tensioned.”

- “Press the belt with your thumb until it deflects about 1/2 in.”

- “Tension the drive until you get a slight bow in the slack side when it is running.”

And then there is this guidance... Again limited on detailed specific tensioning specifics...

How to tension a belt correctly?

- The best tension is the lowest at which belts will not slip or ratchet under the most loaded conditions. You can gradually tighten the tooth by making sure that there is no tooth gap.

- Caution: Excessive tension generates noise and premature wear.

- For V-Belts, check frequently the tension the first day of running. Synchronous belts currently not require re-tensioning or over-checking

- Concerning V-Belts continue checking periodically

- High tension curtails belt and bearing lifetime

- Keep pulleys and belts free of foreign items

- If a V-Belt slides, tighten it.

From the Marine How To website:

Setting Belt Tension

Just like belt alignment, belt tension is critical for optimal alternator performance. Too much tension is not going to necessarily be better than too having little tension. Both extremes are bad. Guessing at belt tension, using the Binford Mark I Thumb Press Tool, unless your really experienced with this, is not likely to result in a good outcome. New belts also need to be “run in” and then re-adjusted. In other words don’t just install a new belt adjust it and walk away. You’ll want to run the belt under load for a period of time then make a second adjustment.

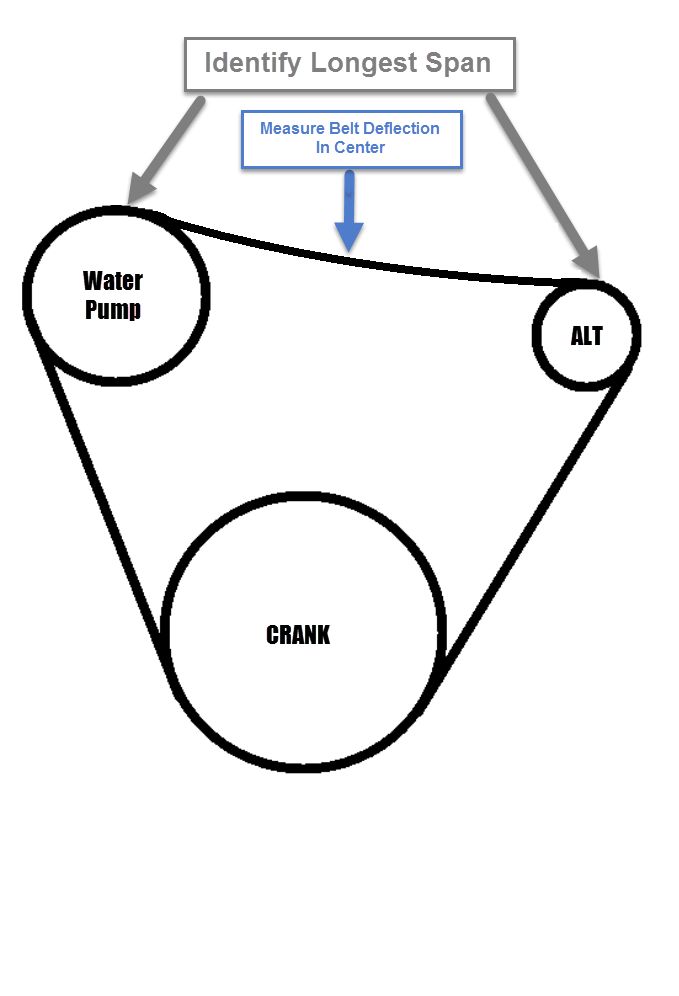

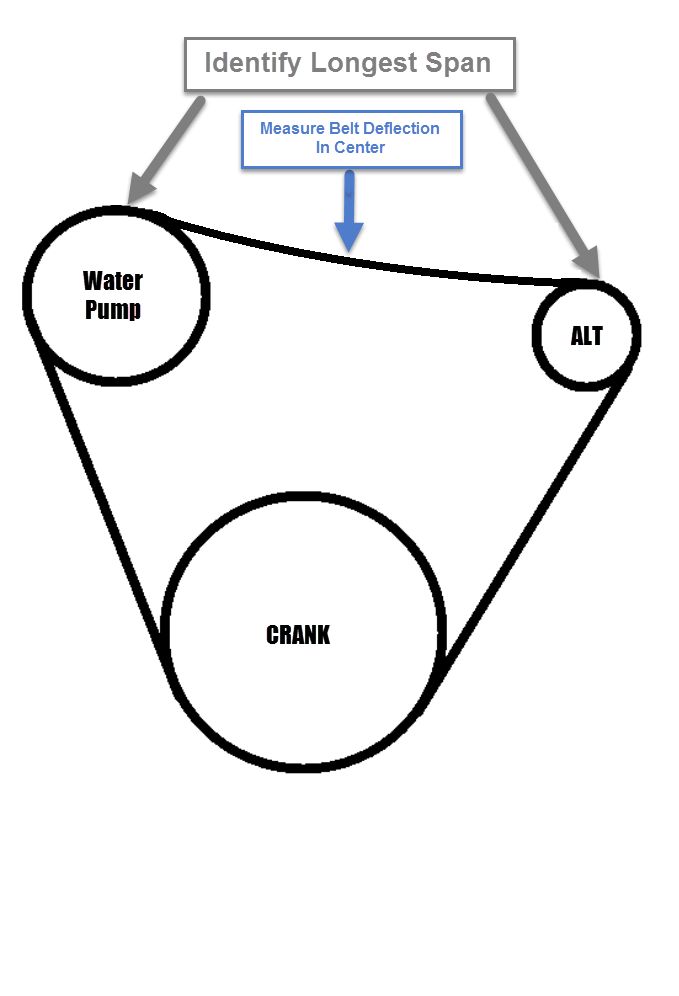

The first step in setting belt tension is to identify the longest pulley span as show below.

Once you’ve identified the longest belt span you can click on over to the Gates web site and used their V-Belt Tension Calculator. Simply input the type of belt you have, the belt width and whether the belt is new or used and it will give you a belt tension number to start from.

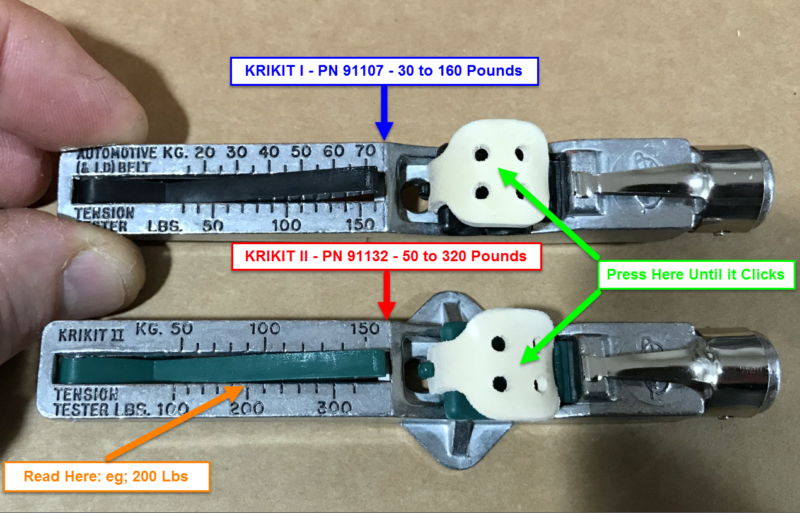

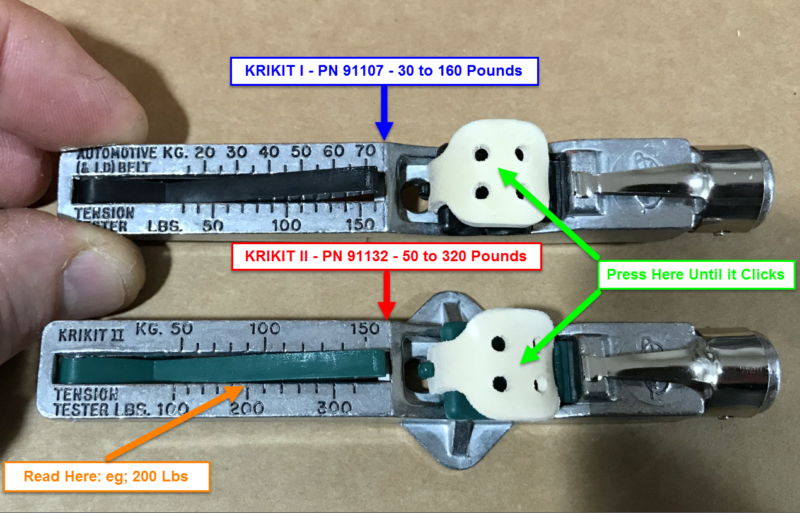

Now that you know what belt tension you need, use of the Gates KRIKIT tools can be used to measure the actual belt tension. A pencil styl tool can also be used but they are more difficult. The Gates KRIKIT tools are inexpensive and pretty easy to use.

Just place the tool in the middle of the longest span, align it in parallel with the belt and press until you hear/feel it “CLICK”. Now carefully remove the tool and read where the plastic arm is flush with the aluminum gauge. There are two Gates KRIKIT tools one goes to 160 pounds and the other to 320 pounds. The most useful for our applications is the KRIKIT II PN 91132 (bottom tool in image below).

The KRIKIT 91107 is available for less than $20

Setting Belt Tension

Just like belt alignment, belt tension is critical for optimal alternator performance. Too much tension is not going to necessarily be better than too having little tension. Both extremes are bad. Guessing at belt tension, using the Binford Mark I Thumb Press Tool, unless your really experienced with this, is not likely to result in a good outcome. New belts also need to be “run in” and then re-adjusted. In other words don’t just install a new belt adjust it and walk away. You’ll want to run the belt under load for a period of time then make a second adjustment.

The first step in setting belt tension is to identify the longest pulley span as show below.

Once you’ve identified the longest belt span you can click on over to the Gates web site and used their V-Belt Tension Calculator. Simply input the type of belt you have, the belt width and whether the belt is new or used and it will give you a belt tension number to start from.

Now that you know what belt tension you need, use of the Gates KRIKIT tools can be used to measure the actual belt tension. A pencil styl tool can also be used but they are more difficult. The Gates KRIKIT tools are inexpensive and pretty easy to use.

Just place the tool in the middle of the longest span, align it in parallel with the belt and press until you hear/feel it “CLICK”. Now carefully remove the tool and read where the plastic arm is flush with the aluminum gauge. There are two Gates KRIKIT tools one goes to 160 pounds and the other to 320 pounds. The most useful for our applications is the KRIKIT II PN 91132 (bottom tool in image below).

The KRIKIT 91107 is available for less than $20

But its another tool I must have!0r use my thumb for free, save $20 for beer...

Must be winter

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,802

Great tool but does it answer the underlying question raised by @marchem in his post "But John, without knowing the force being applied there's no way to use that technique?"

How much force should be supplied? That tool tells you how much force you are applying.

The challenge is, at least I think this is the case, the amount of force is not a specific number. It varies with the machinery. You know there are limits. But it is more of a range than a specific number. Kind of like the judges statements about porn - "You'll know when you see it!"

Your machinery will complain if you tighten the belt too tight, and the belt or the machinery will complain if it is too loose. Like Goldilocks, the belt wants it just right. Then things change and the belt wants you to tighten it a little more.

How much force should be supplied? That tool tells you how much force you are applying.

The challenge is, at least I think this is the case, the amount of force is not a specific number. It varies with the machinery. You know there are limits. But it is more of a range than a specific number. Kind of like the judges statements about porn - "You'll know when you see it!"

Your machinery will complain if you tighten the belt too tight, and the belt or the machinery will complain if it is too loose. Like Goldilocks, the belt wants it just right. Then things change and the belt wants you to tighten it a little more.

We had some $200 belt tension tools at work and found that most average mechanics using the thumb technique were pretty close. 3/8-1/2" with a hard thumb push will get you close and prevent over-tensioning. As above, if it's slipping or squealing under load, tighten a bit and recalibrate your thumb.

I have a inexpensive gauge belt from gates 7401-0076 ( not the cricket) that showed I was under tightening by a lot. For the Universals the manual says to measure tension between the alternator and the main pulley. Most measure it between the water pump and alternator.

If your not measuring it your guessing.

If your not measuring it your guessing.