After having to replace 4 out of 6 chainplate knees due to rot from water intrusion, I wanted to make sure I never had to go through that again. My chainplates were out because I was replacing them in these pictures. You don't have to remove yours to do this. Here is what I did;

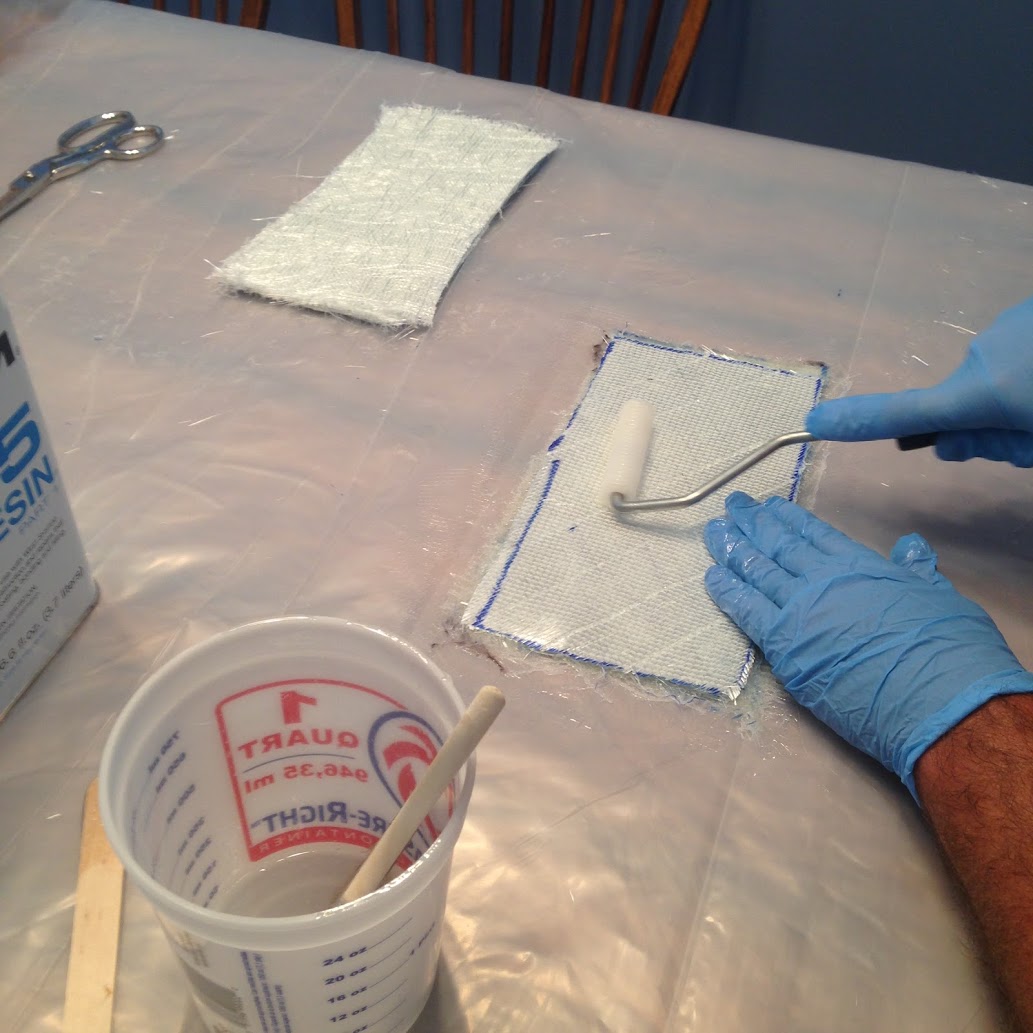

I laminated 10 layers of 1708 biaxial mat into a block.

After that cured I traced the chainplate cover plates onto the block, cut them out with a jigsaw and used a drill bit to cut out the slot the chainplate goes through.

I then made sure they would actually fit over the chainplates.

The new block was then set in place over the chainplate on deck and its location was traced with a pencil. The deck was then sanded to bare fiberglass where the block would be placed. The block was positioned over the chainplate using thickened epoxy. The squeeze out was used to create a fillet. After everything was cured it was painted.

The cover plates were installed using butyl tape.

This raises the hole in the deck that the chainplate passes through and doesn't allow water to pass over an opening. No more leaks!!!

I laminated 10 layers of 1708 biaxial mat into a block.

After that cured I traced the chainplate cover plates onto the block, cut them out with a jigsaw and used a drill bit to cut out the slot the chainplate goes through.

I then made sure they would actually fit over the chainplates.

The new block was then set in place over the chainplate on deck and its location was traced with a pencil. The deck was then sanded to bare fiberglass where the block would be placed. The block was positioned over the chainplate using thickened epoxy. The squeeze out was used to create a fillet. After everything was cured it was painted.

The cover plates were installed using butyl tape.

This raises the hole in the deck that the chainplate passes through and doesn't allow water to pass over an opening. No more leaks!!!

Attachments

-

137.1 KB Views: 309

-

238.6 KB Views: 293

-

68.7 KB Views: 340