I'm trying to attach a 5" x 7" mounting board to the aft port inner hull. The board will carry a diesel heater weighing appox 8 lbs. The hull has a shape but the board is flat thus about 1/4 inch wobble. Would it be better to use a full 3oz tube of 5200 or epoxy to attach? Any other methods of attaching to eliminate the wobble?

5200 or Epoxy?

- Thread starter Head Sail

- Start date

When I'm attaching anything to the rough interior hull, I use a piece of 3/4" plywood calculated out to about 1-2 PSI and then slathered with a tube of silicone sealant. Simply put in place and the silicone sets quickly and doesn't sag while setting. It's also easier to remove than 5200 should you ever decide to re-decorate.

Forget the epoxy as it will continue to sag for hours until it fully sets unless held firmly in place.

Forget the epoxy as it will continue to sag for hours until it fully sets unless held firmly in place.

Thickened epoxy on the back to set the board in place. Make the board a little larger and then taper the edges to fit the hull. Make sure there is a good fillet around the board and then tab it into hull with 2 layers of glass and epoxy extending several inches beyond the board.

Use a fast hardener with the epoxy. Epoxy doesn't need clamping pressure, so tape it in place while epoxy cures or use a stick to wedge it in place for a couple of hours.

Use a fast hardener with the epoxy. Epoxy doesn't need clamping pressure, so tape it in place while epoxy cures or use a stick to wedge it in place for a couple of hours.

5200 is just too strong. I would use thickened G-Flex epoxy. It happily fills gaps. And isn't brittle like regular epoxy. Don't slather it all over the place. Just put a 1" diameter spot or bead every six inches around the perimeter. And like all West Epoxy, a heat gun will get it to let go without damaging the fiberglass. The tubes recap and last a long time. The only downside is it takes overnight to harden so you need to hold the panel while it hardens (although it doesn't need to be clamped). Be sure to clean the fiberglass and the wood with alcohol or similar solvent before glueing. G/flex 655 Thickened Epoxy Adhesive • WEST SYSTEM

The downside of silicone is that if you need to remove it there will likely be a hard to remove residue that nothing sticks to. It’s possible to remove the residue, but not necessarily much easier than other options.Agree on the idea of silicon. 5200 should be considered permanent and wood equals (the possibility) of rot which means it will require replacement sometime in the future. Silicon should be plenty strong for the mount and can be removed as noted.

Personally, when doing anything permanent on fiberglass, I prefer epoxy. For wood, I would always treat all sides with a couple coats of normal epoxy, to slow (if not eliminate) rot. I'd then use either thickened epoxy or a tube of GFlex or 6Ten (both West Systems products, but there are others) to cement it in place. Thickened epoxy will fill your gaps and provide support. For more serious weight bearing, you could fillet around the edges, and add strips of cloth to tab it to the hull, but I'm guessing that for eight pounds, that's overkill. Here's some project stuff, including videos - Epoxy Projects from Epoxyworks Magazine, with WEST SYSTEM Epoxy

If I were doing that job, I'd attach wooden battens to the hull w/epoxy, then screw the shelf into those from above. That way you can remove the shelf at any time, for any reason, without worrying about reattaching it or unglueing anything.

That's the difference between boat building and boat carpentry.

That's the difference between boat building and boat carpentry.

Good point. Especially for something that might need fiddly attachments, like electrical connections.If I were doing that job, I'd attach wooden battens to the hull w/epoxy, then screw the shelf into those from above. That way you can remove the shelf at any time, for any reason, without worrying about reattaching it or unglueing anything.

That's the difference between boat building and boat carpentry.

Actually, nothing sticks to silicone except ........................ silicone. Got a reply from Dow Corning a few years ago and they were the ones who suggested it. The subject was DC 795 which is silicone. Had to try it myself and they were right. 100% adhesion.The downside of silicone is that if you need to remove it there will likely be a hard to remove residue that nothing sticks to.

Attachments

-

4.4 KB Views: 190

1/4" gap is a fair bit. I'd try to shape the board to fit better than that. G-Flex is really easy to work with. The only caution I have is that even the thickened stuff will sag and run before it sets up so damn up the bottom with masking tape. Of course, you will need to fixture it in place with tape or temporary supports.

A lot of work, but I would agree that the board should be made so it will sit flat on the slight curve hull. Either cut a grove or place end pieces. Next, I would glass the board. This will protect it from the environment, and, the best part is you will gain some experience glassing. It might come in handy one day.

JMHO

JMHO

Ditto!If I were doing that job, I'd attach wooden battens to the hull w/epoxy, then screw the shelf into those from above. That way you can remove the shelf at any time, for any reason, without worrying about reattaching it or unglueing anything.

That's the difference between boat building and boat carpentry.

Actually if you want to go cheap on the board, go to Walmart and buy a cutting board. I've used those for various projects and they have always worked well. No cracking or breaking in any weather. I even used one to raise the backrest 6 inches on my scooter. The stuff is cheap and you can usually find many different color choices including white.It is the consistency of play dough and is very strong. I’d also not use actual wood but some Trex like material for the board

The problem with cutting boards is nothing sticks to them. They would work well screwed into battens glassed to the hull or bulkhead.

Also remember in the OPs application he is installing a heater. That will warm the rear and make make some materials unsuitable. One of the last things he wants to have happen is for the heater to fall off while running.

Also remember in the OPs application he is installing a heater. That will warm the rear and make make some materials unsuitable. One of the last things he wants to have happen is for the heater to fall off while running.

Good thought. I should mention that I plan on screwing 2 shelf brackets with wood shelf onto the hull mounted board to support the heater. Battens (vertical or horizontal) would take out some wobble but maybe four 1" pads to attach the shelf brackets would take out even more. Thanks!If I were doing that job, I'd attach wooden battens to the hull w/epoxy, then screw the shelf into those from above. That way you can remove the shelf at any time, for any reason, without worrying about reattaching it or unglueing anything.

That's the difference between boat building and boat carpentry.

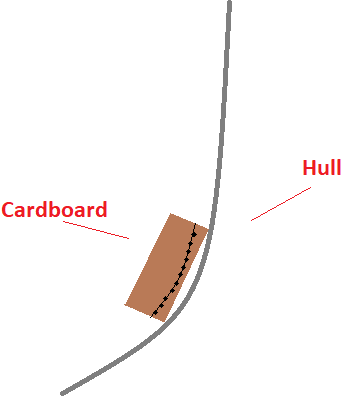

If you decide to try to route the curve into the board... an easy (and cheap) way to mark the curve is to get a pice of cardboard, lay it on the hull and then use a drafting compas to poke holes into the cardboard. Then scribe the curve by connecting the holes. You can even fab a compas out a bent piece of wire.