Most thru hull fittings use straight threads. the easy way to tell is to look and see if your thru hull's have a nut on top of the backing block. In all three photos this looks to be what was installed by the OEM was a NPS threads (the "S" stands for straight). The IBV series suggested by Maine Sail uses NPT threads (the "T" stands for tapered). Although they appear to fit together, the Tapered threads do not seat firmly on the Straight Threads. That means that your threads will be mismatched requiring tons of pipe joint compond. However Groco has addressed this common problem in older boats their IBVF series. The IBVF thru hull fittings uses straight threads on the thru hull end and tapered threads on the fitting end.

Bria is correct. What you have, and many production boats have, is a thread mismatch between a straight threaded thru-hull and the tapered thread ball valve.. This type of installation does not meet ABYC standards.

If however your existing thru-hulls are in good condition and are not showing any signs of corrosion or dezincification (a pink coppery color when the green verdegris is cleaned away) then you can re-use them. If you can get a new valve on with plenty of both teflon tape and pipe dope, all without moving the thru-hull and iota, than you can often get it tight enough for many more years of service. While certainly not the preferred or ideal method, strength wise, thread match wise or current safety standards wise, it can work. Would I do it? Not on my own boat but there are many boats still floating using this rather poor installation technique......

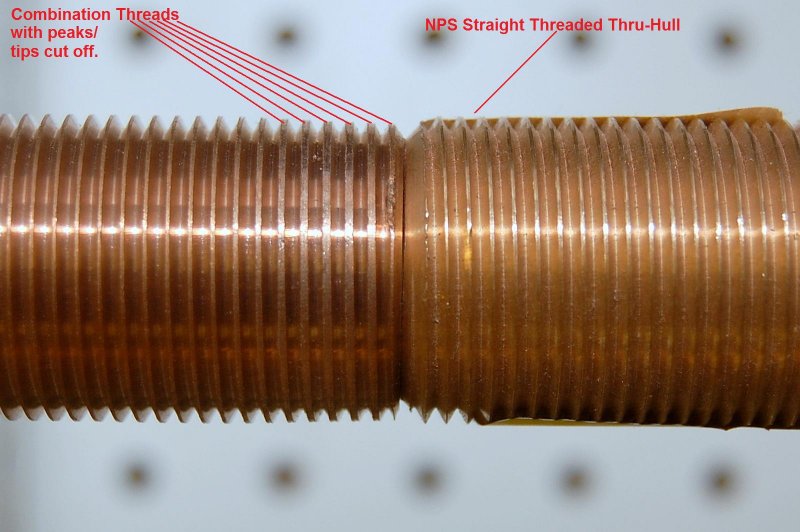

Groco also makes a thru-hull fitting with "combination threads" cut into it. This is a band-aid at best as it is NOT a true tapered thread and only the tips of the thread peaks are shaved of in the hopes of getting a few more turns. The valleys however are no deeper as thes thru-hulls don't have the wall thickness to cut a real "tapered thread" into them without drastically reducing the strength.

This is a combination threaded thru-hull:

The big problem with this design is that you can NOT cut any length off the thru-hull and retain the "combination" threads. This makes your interior hard piped length quite tall/long and ultimately makes the thru-hull an even weaker link than it already is because of the long lever action of the valve and male adapters added height.

If you are getting to the level where the thru-hulls are removed than you'd be wise to use a flanged adapter on the inside. Even if you don't through-bolt it this is a much stronger installation and the threads all match. (See linked articles below)

This is why the ABYC disallows a thread mis-match:

Feel free to read the articles below on seacock and thru-hull installations.

Seacock & Thru-Hull Primer/Pre Information (LINK)

Replacing Thru-hulls & Seacocks (LINK)