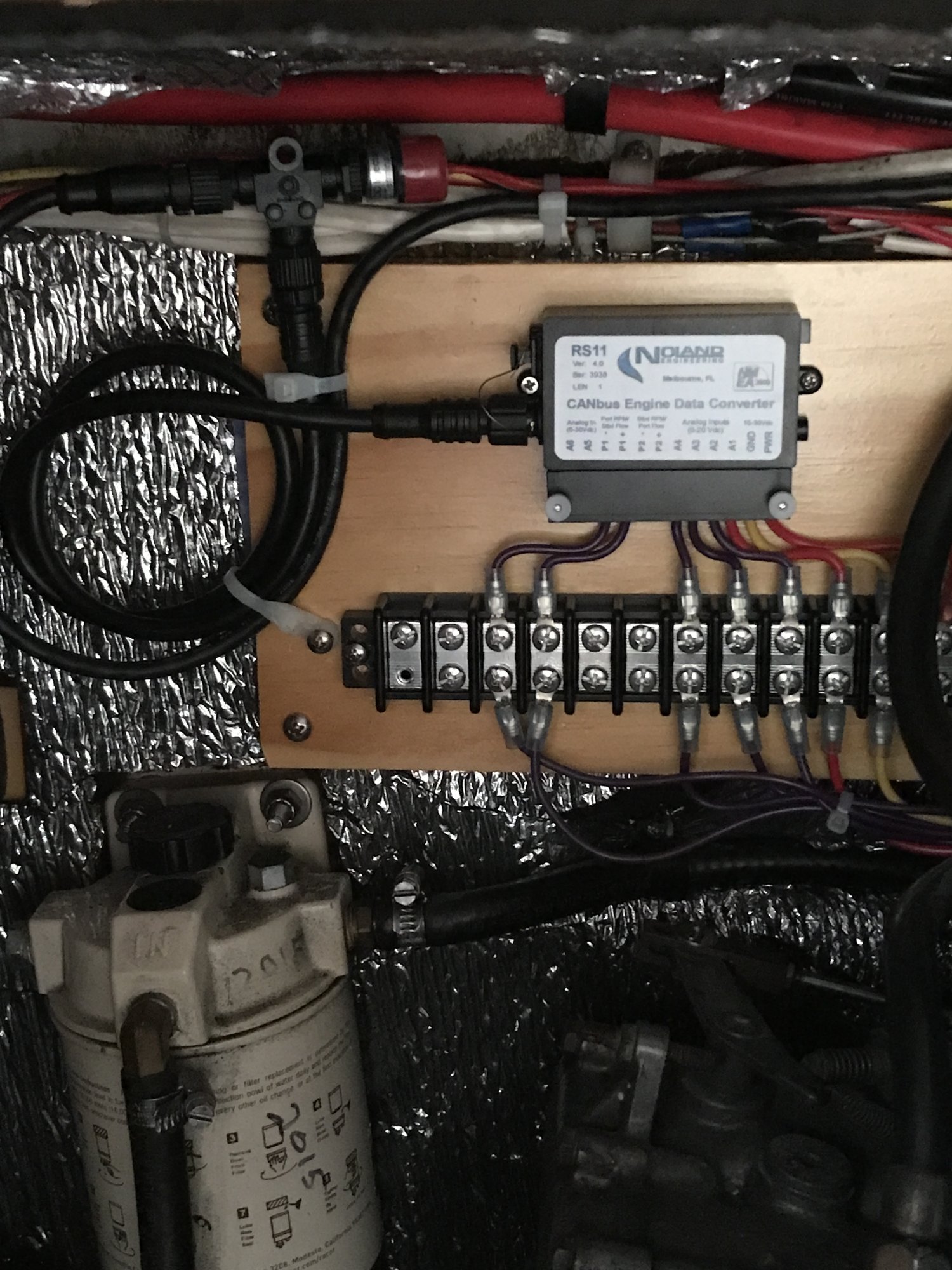

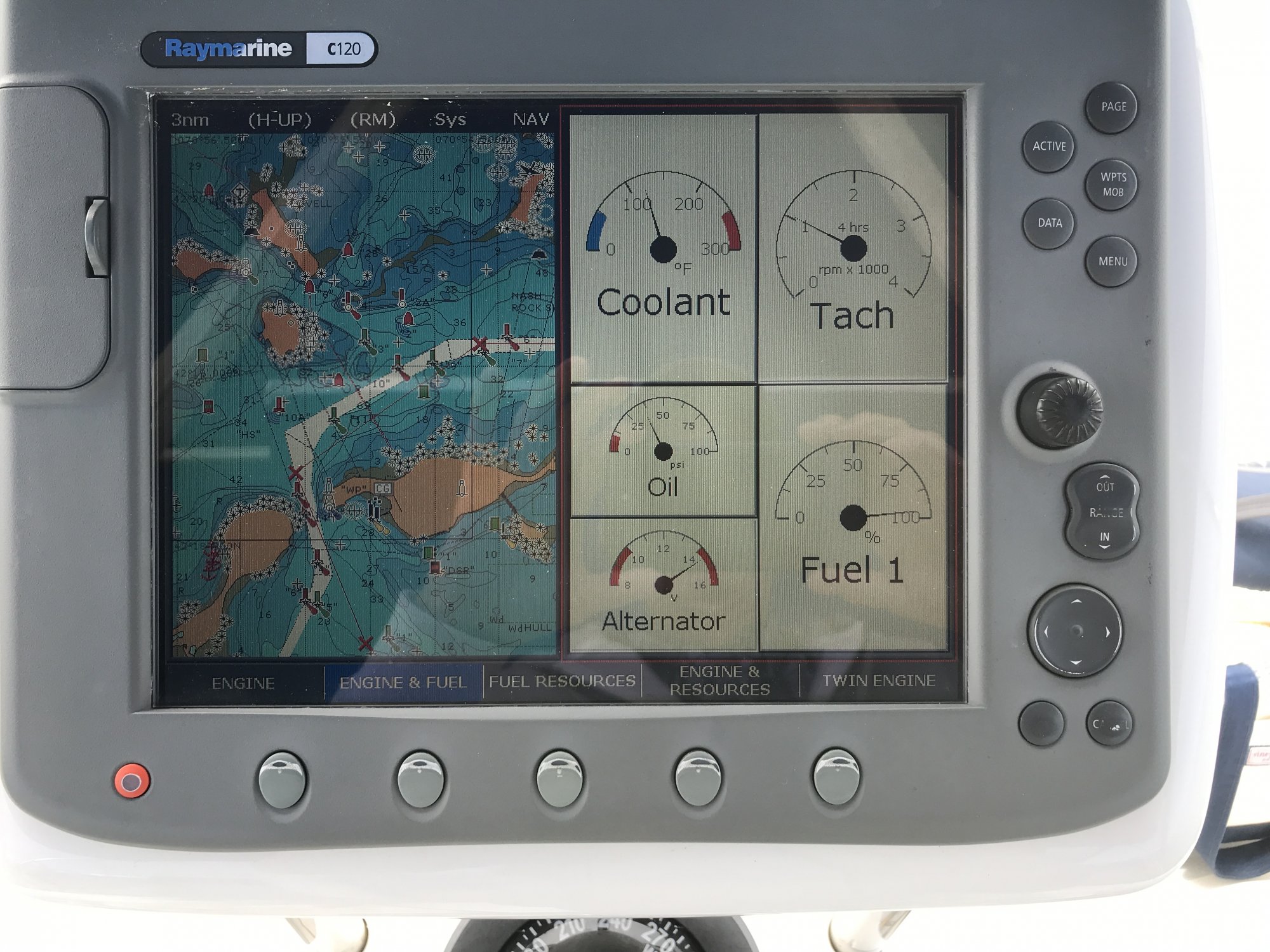

Details: The installation was somewhat limited by my old Raymarine C120 plotter. That plotter can only display certain instrument inputs. Ammeter, for example, is not available. Further, the C120 has an input port for the NMEA2000 cable buss but it is not directly connectable to the standard cable end and no adaptor is available. That port is what Raymarine refers to as Seatalk2. I had to cut the Seatalk2 end off of a Raymarine cable and splice it to a standard NEMA2000 cable, matching wire colors. The Noland rs11 device is, to me, overly delicate with wire inputs similar in design to a home thermostat. I added a more robust terminal strip and mounted both to a backboard that you can see in the photo. Connecting to the engine is not difficult. You connect a new wire (I used 16Ga throughout) from a terminal on the rs11 to each existing instrument sender wire. You can connect the new rs11 wire to either end of the existing sender wire; at the sender end or at the gauge end. This does not alter the existing gauge reading. You can also add a new sender to your engine without a gauge and connect that directly to the rs11. I did just that with a new oil pressure sender which I did not have before. You are required to use a windows based laptop to set the rs11 up for your particular application. The instructions that came with the device were not very good concerning the Windows application and I had to get an expert (my grandson) to help me with that part of the project. The rs11 comes with the software required to configure the device. Instructions could be improved but you can muddle through. The NEMA2000 cable buss that runs from the rs11 to the plotter is all standardized and you can mix and match any company's components and they will connect together.

This project's costs were low for a boat project. In round numbers, $400 for the rs11, $100 for wire and cables, $100 for the oil pressure sender that I never had before. In labor (all mine) many internet hours were not recorded researching compatibility with my old chartplotter. An email to Noland concerning this was never answered. I proceeded on faith and was eventually rewarded with success. Actual wiring on the boat was probably about six hours. Calibrating and configuring with the laptop was difficult due to the instruction shortcomings and the ever changing patchwork Windows operating system. I spent maybe six hours here but someone more familiar with Windows and perhaps more computer oriented would take far less time.

It will be nice to be able to monitor my engine from the helm by simply glancing at the plotter. My original gauges are at shoe level and my eyesight is not as good as it should be. I hope my explanation is comprehensive enough to convince you to either proceed with the project on your boat or give it a pass. Feel free to ask me any questions.