A couple of weeks ago there was a discussion in another thread about using marine grade plywood vs cabinet grade plywood.

Both types share some important characteristics, as they are stable, have few if any knots, and at least one attractive face. A question was raised about the glues used on each type, with waterproof glue in marine ply and not waterproof glue in cabinet ply.

ln the basement I had a piece of scrap marine and a piece of scrap cabinet ply, each took a 9 day bath in their respective cups.

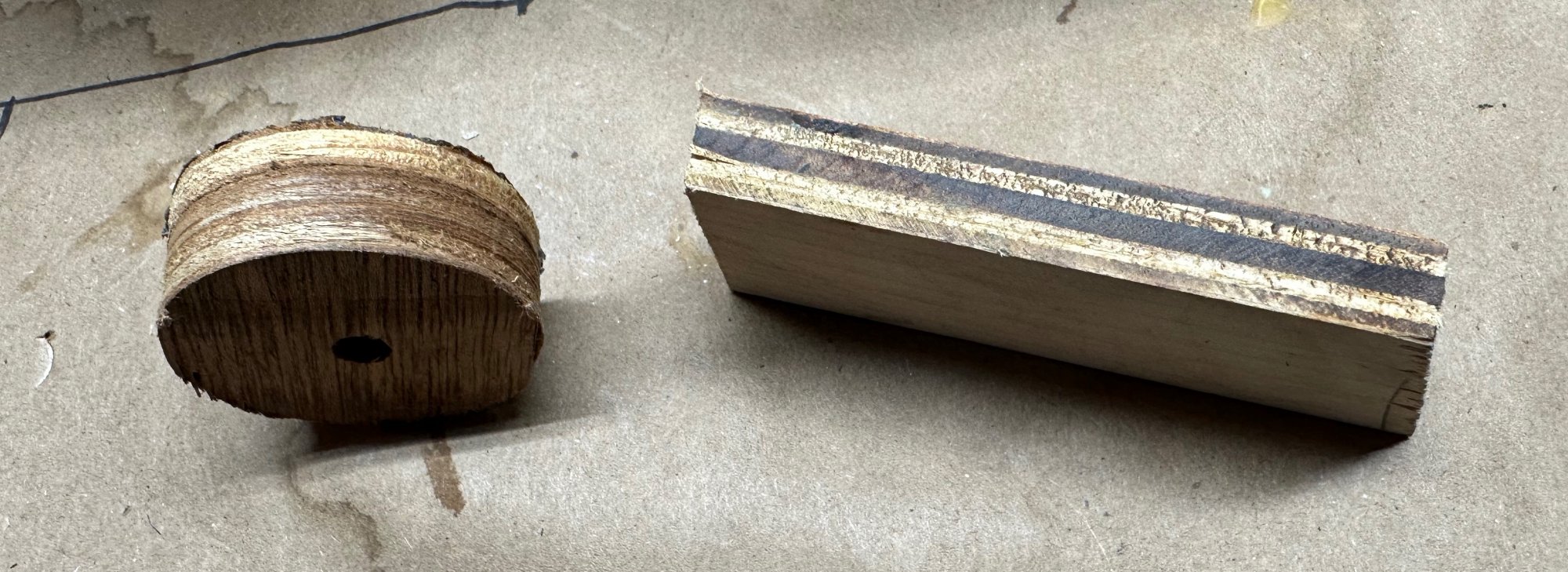

The round piece is marine ply from a hole drilled into a bulkhead. It is actually 2 pieces of ply glued together. This is a boatbuilder's trick to reduce cost, use basic marine ply (less expensive) and add a veneer of expensive ply with teak, cherry, or some other exotic wood to build up the thickness and provide an attractive face.

Nine days later.

The veneer ply was clearly attached with a water soluble glue. It separated within a day or so. The cabinet grade and the marine grade show little or no delamination. Water soluble glue does not appear to have been used on the cabinet grade. The little bit of ply separation may mean the glue is water resistant if not water proof. The marine ply showed no separation.

Can cabinet grade ply be substituted for marine grade? If the application includes frequent dunking in water, sitting in water, or is structural then marine grade is probably a better choice. For other applications, cabinet faces, mounting blocks, deck core, and any where the plywood will be sealed with epoxy, then I think cabinet grade is an economical choice.

Both types share some important characteristics, as they are stable, have few if any knots, and at least one attractive face. A question was raised about the glues used on each type, with waterproof glue in marine ply and not waterproof glue in cabinet ply.

ln the basement I had a piece of scrap marine and a piece of scrap cabinet ply, each took a 9 day bath in their respective cups.

The round piece is marine ply from a hole drilled into a bulkhead. It is actually 2 pieces of ply glued together. This is a boatbuilder's trick to reduce cost, use basic marine ply (less expensive) and add a veneer of expensive ply with teak, cherry, or some other exotic wood to build up the thickness and provide an attractive face.

Nine days later.

The veneer ply was clearly attached with a water soluble glue. It separated within a day or so. The cabinet grade and the marine grade show little or no delamination. Water soluble glue does not appear to have been used on the cabinet grade. The little bit of ply separation may mean the glue is water resistant if not water proof. The marine ply showed no separation.

Can cabinet grade ply be substituted for marine grade? If the application includes frequent dunking in water, sitting in water, or is structural then marine grade is probably a better choice. For other applications, cabinet faces, mounting blocks, deck core, and any where the plywood will be sealed with epoxy, then I think cabinet grade is an economical choice.