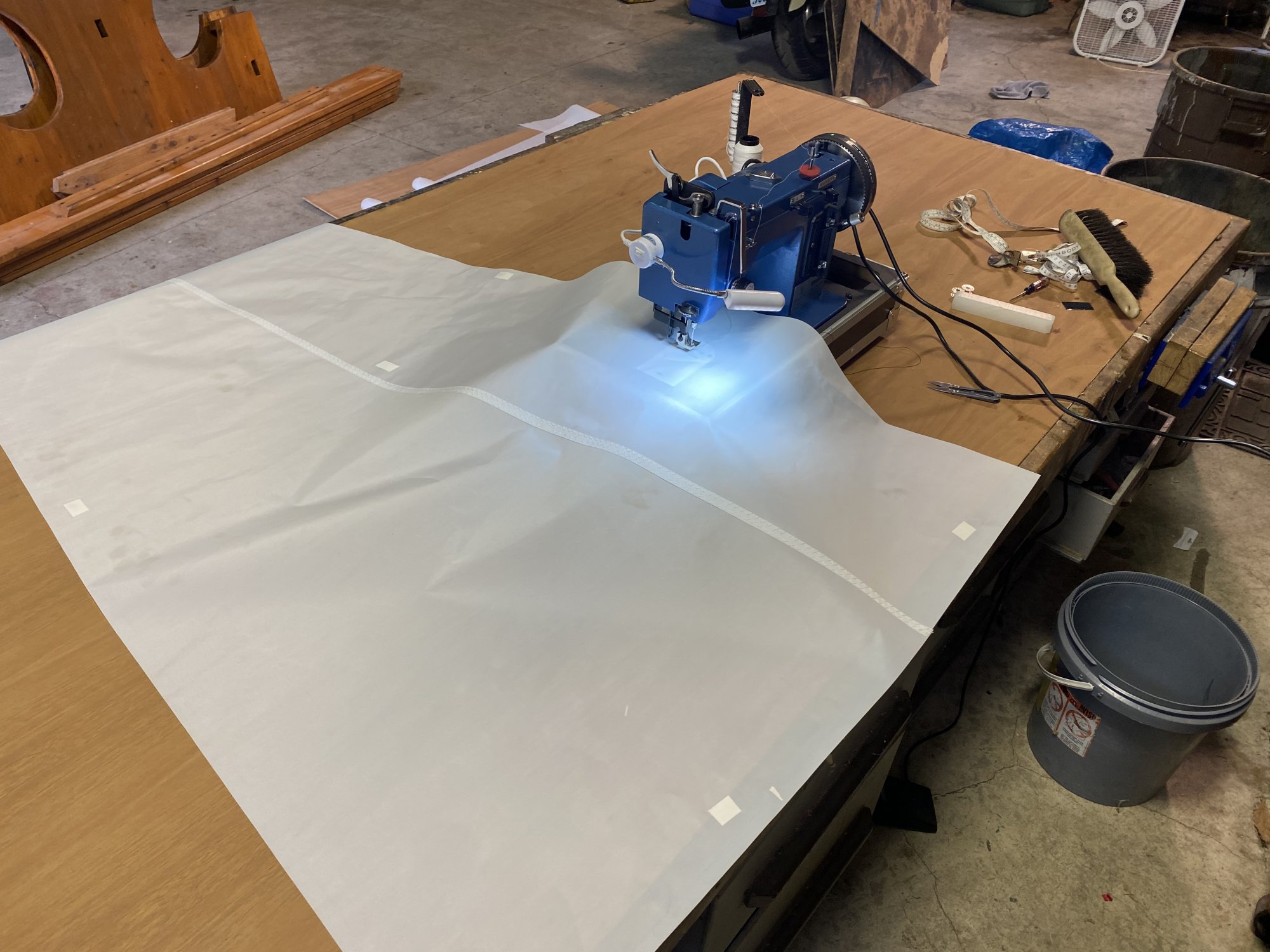

Started my Laser sail kit today and I’m very impressed. It is well laid out and the instructions are clear. The only thing I would include in them is a sequence of work flow. There is a key to the workflow given the size of the project pieces vs the capacity of a Sailrite machine. I also feel the sail is a little overbuilt compared to previous Laser sails I have had. Extra reinforcements compared to Laser spec sails. I’d be very happy with its construction on my Hunter 30 but as a racing dinghy it’s a little overkill. The price is just a touch under a made practice sail but I wanted to give it a try. Looking at kits for my Hubter 30, the pricing is about 1/3 of a comparable, professionally made sail. I think I know we’re my next set is coming from!

Last edited: