Next big project:

It's raining! Inside. Harder than it is outside

I have a leak. Well, to be honest, it's not a new leak, it's been a thorn in my side since forever. The companionway hatch has always leaked, varying from a mild annoyance to a waterfall-esque deluge. It currently is the waterfall and all stems from the basic design:

The hatch (#1) is 3/8" acrylic which is captured and slides in an aluminum extrusion (#2) which has a fiberglass cover (an arm molded into the big hatch cover). The extrusion is screwed to the deck and extends forward underneath the cover the length of the opened hatch. All good so far except that over time the groove in the extrusion traps leaves, dirt and debris. This is made worse because the fiberglass arm covers, where they terminate at the aft end (#3) are closed so there is no way for water to drain, thus making the trapped dirt and debris even worse. The arm ends also capture the hatch so it will not slide out the aft stops. To make things even worse the hatch cover is open to the elements, with openings at each side that run completely through for the halyard runs. So there is no way to seal up the area under the hatch cover.

I have removed the hatch cover several time over the years to clean everything underneath and try to fix the basic problem of debris buildup but - tweaks to a poor basic design will never fix the problem of - a poor basic design

. The problem is made even worse by two additional elements - the deck forward of the (closed) hatch is flat, which allows water and debris to collect there, and over time the hatch has developed a sag which allows water to pool on the hatch itself when it rains.

So what to do? I have had this repair/redesign on the long-term list for a while but I was below during the rainstorm we got here a few days ago and I swear water was pouring in faster with the hatch closed than if the hatch was open! The hatch needs some fixing now instead of later since I'm really concentrating on getting the interior done.

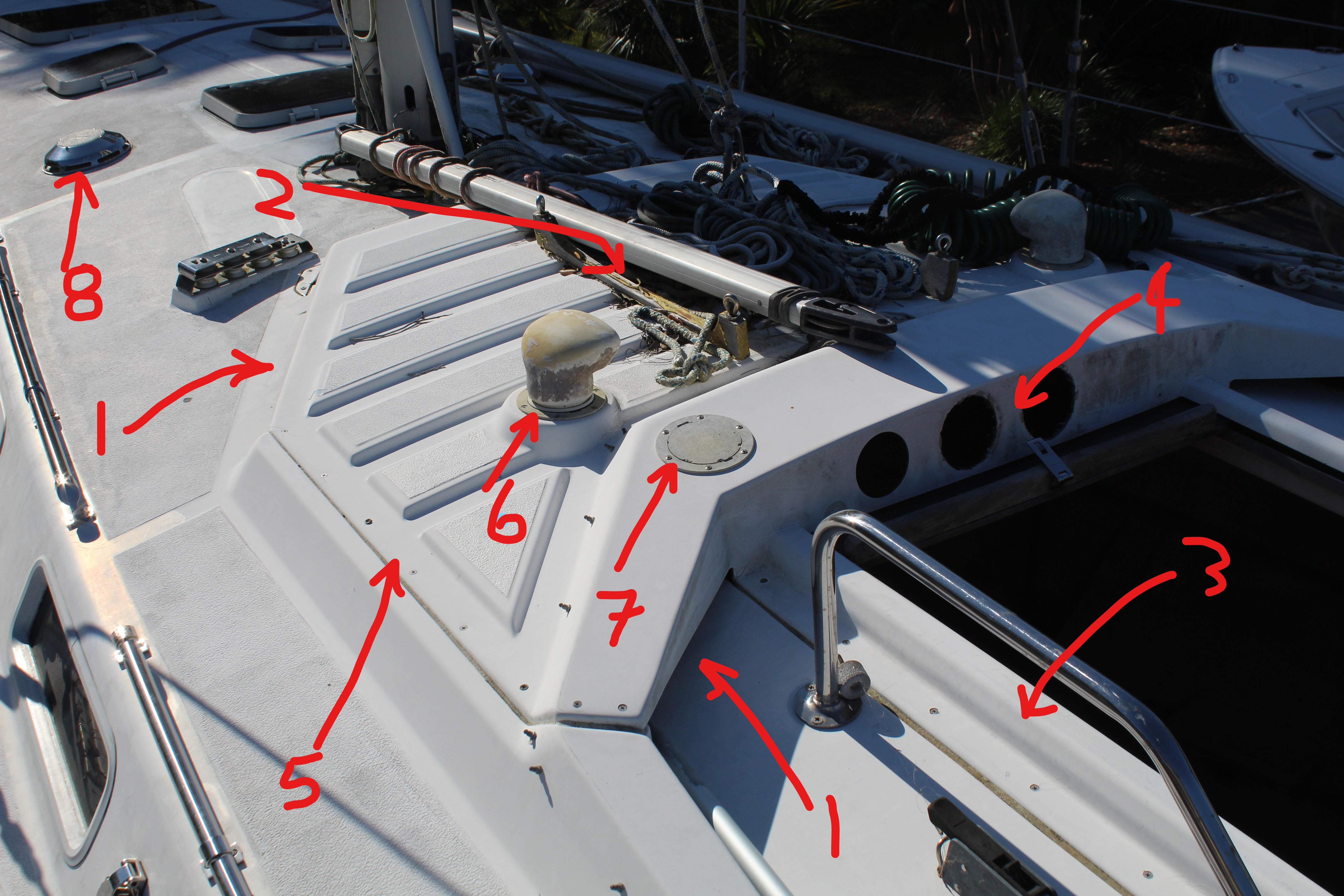

Fixing the hatch itself only cures half of the problem - the hatch cover is the real problem. It's screwed to the deck and is big, heavy and bulky so removing it routinely to clean underneath is not an option so I have to deal with the hatch cover as part of the fix.So here's the hatch highlighted with concern areas:

1: openings fore and aft for the halyard runs, biggest entry area for debris.

2: The area under the hatch cover is totally open with about 3 or 4 inches clearance to the deck but with no real way to access this area.

3: The integrated hatch arm covers.

4: Old area for sailing instruments. No longer needed.

5: Attachment points around the perimeter for the cover. All these screw holes are in bad shape and need lots of fixing.

6: Dorades - I can't really figure out how these are supposed to work. based on my (admittedly limited) knowledge of how a dorade is supposed to work vs. this setup.

7: No clue why there is a deck plate here!

8: These Nico vents for the cabin haven't worked in years, so I have to replace them with something. Maybe build a dorade here?

Overall the hatch cover, were I to refurbish it in it's present form, would need a ton of rehab to get it back into good shape so I'm thinking maybe a redesign of the hatch cover in conjunction with remaking the hatch itself might be the answer. To add a complication into the mix I have to integrate a dodger as well.

I'm mulling over several ideas but any thoughts from you guys?

Cheers,

Mark

. The problem is made even worse by two additional elements - the deck forward of the (closed) hatch is flat, which allows water and debris to collect there, and over time the hatch has developed a sag which allows water to pool on the hatch itself when it rains.

. The problem is made even worse by two additional elements - the deck forward of the (closed) hatch is flat, which allows water and debris to collect there, and over time the hatch has developed a sag which allows water to pool on the hatch itself when it rains.