If you

all will note, there is NO Elevation view (side view of his boat). To design and give firm advice, the boat's static water level is needed, relative to the pictures.

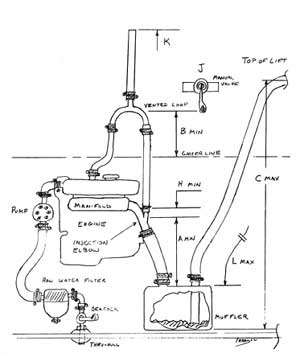

This is from my Hunter manual which includes the PLAN view (looking down) and the ELEVATION view.

@kloudie1 note the elevation view "Loop"

prevents healed forward motion "water pressure" blow back, on my boat. That loop also provides the seal loop for the exhaust and causes the "burping" effect of engine exhaust, as the engine exhaust pressure "burbs out" the riser quench water.

@nveater

the engine guy believes that water got into the cylinder from being syphoned

I

suspect you have a

restricted muffler/exhaust system. Which might have shown a "tough or long" cold start.

______

A siphon is a "dynamic" event. If there is no

flow... no siphon. It is a Reverse

flow normally.

_______

IMHO there is only one reason for the vented high loop....

Prevent siphoning from the sea water pump.

This siphon can happen with a worn pump impeller, if it was properly installed.

If that is the possible water source, then simply shut the sea cock or make sure your vent works. The elevation of that vent must be above your water pump (which it is)

and above the static water line.

__________

Since there is water in the seal loop of the muffler system, I have always worried about high sea's SLOSHING of that water backwards. I will aways run my engine, if in high "fore and aft" seas

Jim...

PS: I got the static water level, on my boat, buy using a tap measure and seeing the tape through a port light. Then moving the from port light reference to my engine compartment.