........... for this 1999 Hunter 310 owner. And maybe a few others as well.

In the last fourteen years, I thought I had plumbed every nook, crevice, and cranny in the boat and no further surprises could possibly exist. Yeah, you bet. I also hear the Pope's converting to Judaeism.

While replacing my macerator pump a few weeks ago, I found that the hose to the deck pump out didn't look as good as it could under the gear clamps. What could be easier than replacing the hose ? Two hour job tops in addition to the one week I'd already spent on the new macertor installation. Hell, the macerator replacement was only supposed to be an hour. So .................. first thing is to disconnect the hose down near the tank.

Maybe this'll only be a one hour job, tops. Next is to disconnect the hose from the bottom of the deck fitting. This is accessed through a panel in the rear of the medicine cabinet. Now this is interesting, how does one get their big meat hooks up behind the wall in order to undo the two gear clamps. You can't even slip a piece of paper in here, and surely not a screw driver, and loosen two hose clamps up in there ? ? ? Sure, and for my next trick, I'll be turning water into wine.

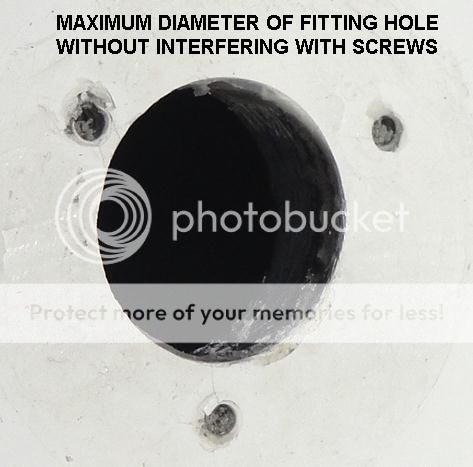

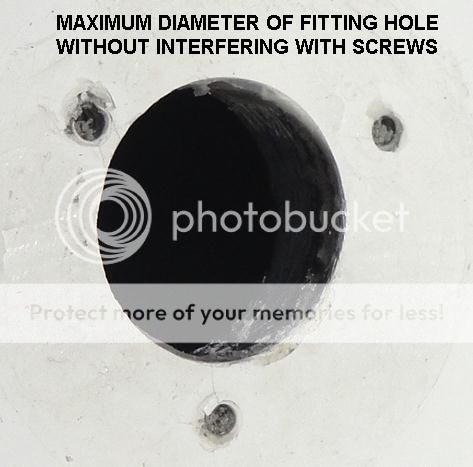

So, these boat assemblers were smart. The way you disconnect it is to go out on deck, dislodge the deck fitting, and pull out the SS deck fitting, followed by the gear clamps and finally the hose. No, not exactly. The hole in the deck for the fitting is just big enough to accept the deck fitting and no more. Any bigger and the screws would be screwed into thin air. The hose and the gear clamps are NOT coming through this hole on a bet.

I now see these assemblers were beyond smart. Mechanical geniuses at least. So how the hell'd they put it together ?

Down below again and look behind the medicine cabinet. Wait for the answer to pop out of thin air. Absent-mindedly place my hand on the hose and wiggle it. The hose drops, my jaw drops, and I'm left with a sewage hose hanging in mid air. These characters had managed to push the hose, at a lenght of about a foot, onto the barbed fitting for all of 1/4 inch. Sort of like pushing on a rope. I was so gobsmacked, I couldn't even let loose with the usual barrage of obscenities.

So just how the hell does one manage to get the pump-out hose on the barded fitting and crank up a couple of gear clamps in a space that's so small there isn't even enough room to spit ? Desperation is the real mother of invention.

Unscrews the stainless fitting from the deck, and sure enough, you can see how far the hose was on the fitting ............. about 1/4 inch . There truly must be a god of the sea or how else did this hose stay on the barb for 14 years without falling off ? Or, maybe all this stuff about about carefully fitting hoses on to barbed fittings is all a load of crap. Just slip it on a quarter of an inch and forget it. Look ma, no hose clamps

. There truly must be a god of the sea or how else did this hose stay on the barb for 14 years without falling off ? Or, maybe all this stuff about about carefully fitting hoses on to barbed fittings is all a load of crap. Just slip it on a quarter of an inch and forget it. Look ma, no hose clamps  .

.

I can feel insanity setting in and decided to get out of the marina, running. After a few hours of staring at the fitting, it comes to me ...... maybe.

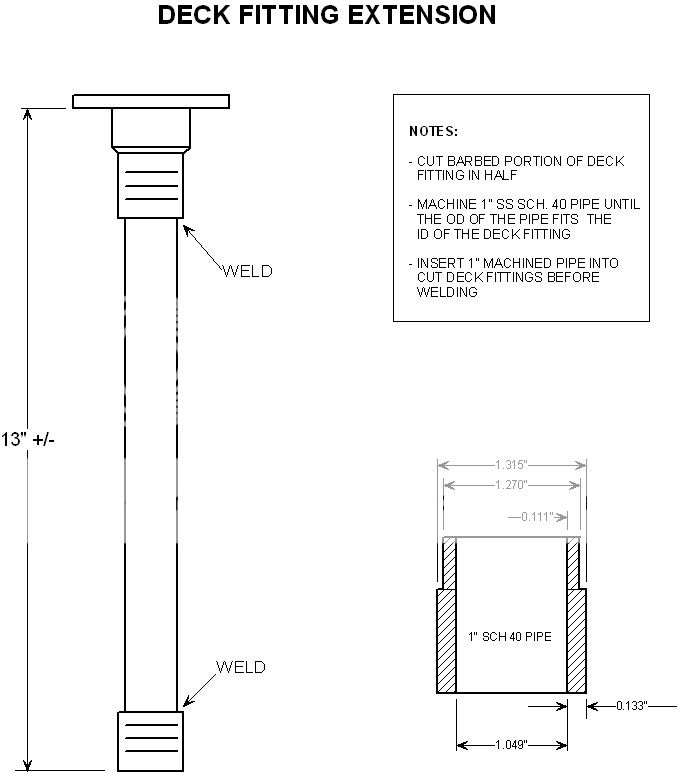

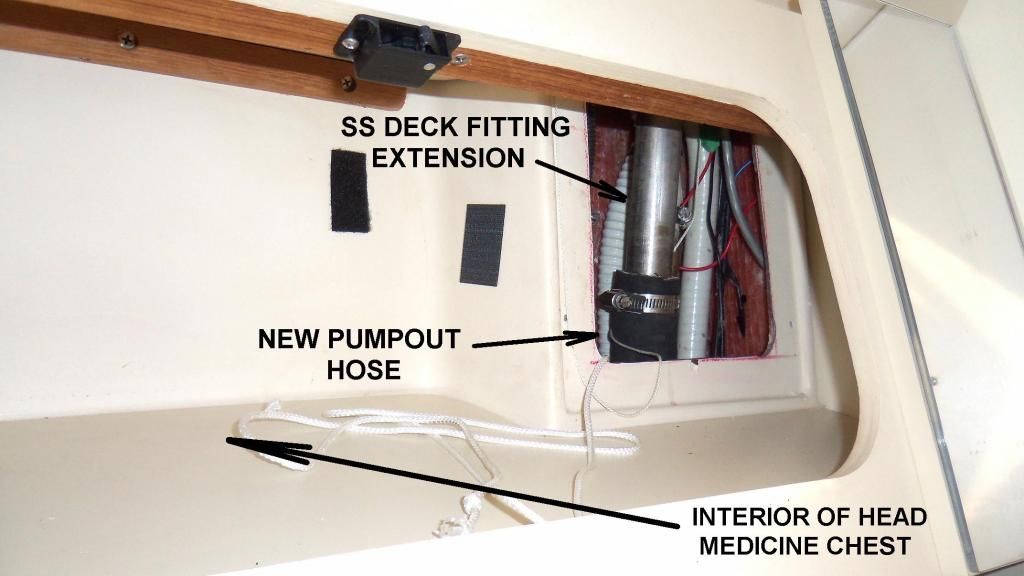

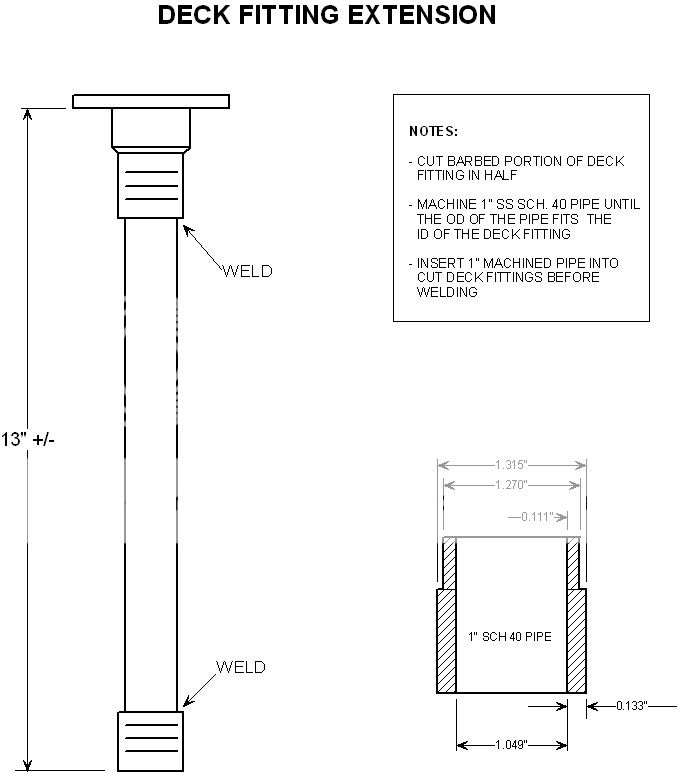

If we extend the length of the stainless fitting down to the opening in the medicine chest, we can jam the hose on there and finally apply two hose clamps. Two clamps because I just couldn't bear to have a leak way back there on my toothbrush.

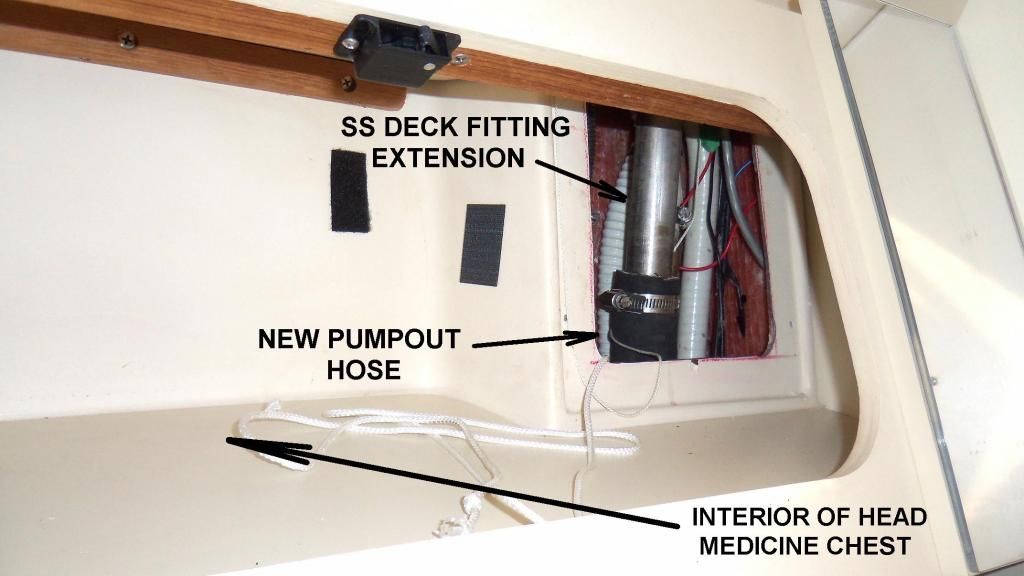

Back from the machine shop with this weird looking 13 inch long deck pump out fitting and we're ready to install.

Fortunately, it was easy to run the new hose from there.

Unfortunately I now have this insane compulsion to jam my head into tiny little spaces on the boat looking for another hidden screw up. I know it's in there ......... somewhere ............. I've just GOT to find it .

.

In the last fourteen years, I thought I had plumbed every nook, crevice, and cranny in the boat and no further surprises could possibly exist. Yeah, you bet. I also hear the Pope's converting to Judaeism.

While replacing my macerator pump a few weeks ago, I found that the hose to the deck pump out didn't look as good as it could under the gear clamps. What could be easier than replacing the hose ? Two hour job tops in addition to the one week I'd already spent on the new macertor installation. Hell, the macerator replacement was only supposed to be an hour. So .................. first thing is to disconnect the hose down near the tank.

Maybe this'll only be a one hour job, tops. Next is to disconnect the hose from the bottom of the deck fitting. This is accessed through a panel in the rear of the medicine cabinet. Now this is interesting, how does one get their big meat hooks up behind the wall in order to undo the two gear clamps. You can't even slip a piece of paper in here, and surely not a screw driver, and loosen two hose clamps up in there ? ? ? Sure, and for my next trick, I'll be turning water into wine.

So, these boat assemblers were smart. The way you disconnect it is to go out on deck, dislodge the deck fitting, and pull out the SS deck fitting, followed by the gear clamps and finally the hose. No, not exactly. The hole in the deck for the fitting is just big enough to accept the deck fitting and no more. Any bigger and the screws would be screwed into thin air. The hose and the gear clamps are NOT coming through this hole on a bet.

I now see these assemblers were beyond smart. Mechanical geniuses at least. So how the hell'd they put it together ?

Down below again and look behind the medicine cabinet. Wait for the answer to pop out of thin air. Absent-mindedly place my hand on the hose and wiggle it. The hose drops, my jaw drops, and I'm left with a sewage hose hanging in mid air. These characters had managed to push the hose, at a lenght of about a foot, onto the barbed fitting for all of 1/4 inch. Sort of like pushing on a rope. I was so gobsmacked, I couldn't even let loose with the usual barrage of obscenities.

So just how the hell does one manage to get the pump-out hose on the barded fitting and crank up a couple of gear clamps in a space that's so small there isn't even enough room to spit ? Desperation is the real mother of invention.

Unscrews the stainless fitting from the deck, and sure enough, you can see how far the hose was on the fitting ............. about 1/4 inch

I can feel insanity setting in and decided to get out of the marina, running. After a few hours of staring at the fitting, it comes to me ...... maybe.

If we extend the length of the stainless fitting down to the opening in the medicine chest, we can jam the hose on there and finally apply two hose clamps. Two clamps because I just couldn't bear to have a leak way back there on my toothbrush.

Back from the machine shop with this weird looking 13 inch long deck pump out fitting and we're ready to install.

Fortunately, it was easy to run the new hose from there.

Unfortunately I now have this insane compulsion to jam my head into tiny little spaces on the boat looking for another hidden screw up. I know it's in there ......... somewhere ............. I've just GOT to find it