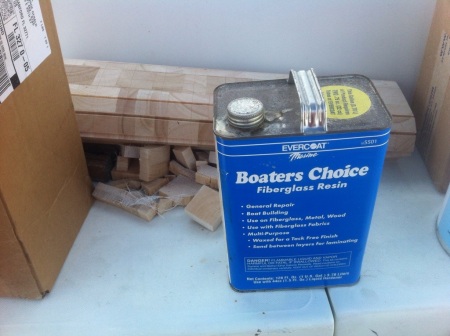

Today I started my cockpit floor restoration. I cut around the outer edge and proceeded to peal up the skin.

Everything was going well until I started in my attempt to remove the rotten core. It appears that a PO had poured a very large volume of stop rot down into the void. A majority of the plywood is now an epoxy of rotten wood that is firmly bonded to the liner fiberglass.

Attempts to pry it up have been unsuccessful as the pry bar just chips a small area off the edge or starts to dive into the glass liner.

At this point I am open to suggestions.

I guess I can cut my new end grain balsa core to fit the few open spaces but I have concerns about uneven thickness and strength of the core once I seal it up.

In addition the skin I removed has about 1/8 an inch of this stuff as adhered to the underside. I am thinking of just using all new glass and doing a kiwi grip no skip finish to hide my work.

Ugggg.

Everything was going well until I started in my attempt to remove the rotten core. It appears that a PO had poured a very large volume of stop rot down into the void. A majority of the plywood is now an epoxy of rotten wood that is firmly bonded to the liner fiberglass.

Attempts to pry it up have been unsuccessful as the pry bar just chips a small area off the edge or starts to dive into the glass liner.

At this point I am open to suggestions.

I guess I can cut my new end grain balsa core to fit the few open spaces but I have concerns about uneven thickness and strength of the core once I seal it up.

In addition the skin I removed has about 1/8 an inch of this stuff as adhered to the underside. I am thinking of just using all new glass and doing a kiwi grip no skip finish to hide my work.

Ugggg.

Attachments

-

488.2 KB Views: 411

-

447.5 KB Views: 407

-

623.5 KB Views: 390