While making a passage from Galveston to Tampa Bay in our Beneteau Oceanis 37; We spent 4.5 days in a storm that was up to force 8. The factory wire connection to our R&D navigation lights located in the anchor locker parted due to corrosion and we had to sail 3 nights without the R&G.

The connection was crimp with shrink tube, one wire to two wires. The shrink tube could not totally prevent the ingress of saltwater between the two wire exit.

During my sleep deprived period at the helm; My mind pondered on ways to guarantee a truly watertight connection.

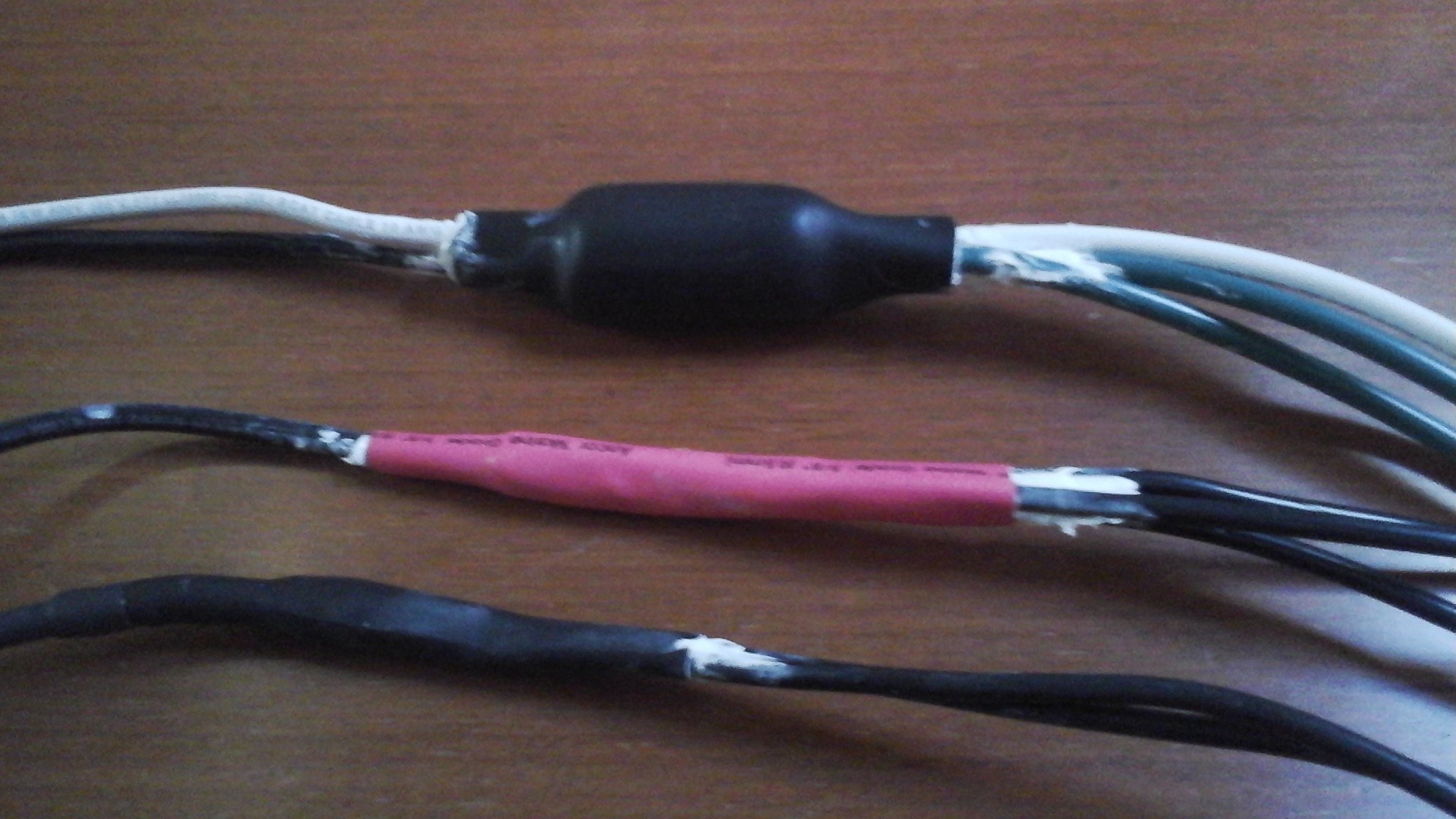

This is what I came up with. Make a crimped connection like normal but next use an oversize shrink tube and shrink on end slightly so it can slide over the wire. Slide it up to the connection. Fill the tube with Life Seal and slide the tube over the connection or connections. The life seal squeezes up around the connection. If you want you can add more Life Seal. Now shrink the other end. You can knead the Life Seal in the tube if you choose. Now slowly shrink the rest of the tube. Life Seal will ooze out each end. Stop at that point. You can shrink the ends tight if you want. You will notice where multiple wires exit your connection the Life Seal has completely sealed all the gaps.

Let cure and you have a truly watertight joint.

I took a pic of some samples but don,t know yet if I can upload it. It should be attached.

Note: If you want a neater appearance you can take a shrink tube just large enough to fit over your shrunk ends and shrink it down giving a very professional appearance. It doesn't matter if the Seal cures inside the connection though I'm pretty sure over time it will like in your tube. LOL.

You may already know this method but no-one on my dock had.

The connection was crimp with shrink tube, one wire to two wires. The shrink tube could not totally prevent the ingress of saltwater between the two wire exit.

During my sleep deprived period at the helm; My mind pondered on ways to guarantee a truly watertight connection.

This is what I came up with. Make a crimped connection like normal but next use an oversize shrink tube and shrink on end slightly so it can slide over the wire. Slide it up to the connection. Fill the tube with Life Seal and slide the tube over the connection or connections. The life seal squeezes up around the connection. If you want you can add more Life Seal. Now shrink the other end. You can knead the Life Seal in the tube if you choose. Now slowly shrink the rest of the tube. Life Seal will ooze out each end. Stop at that point. You can shrink the ends tight if you want. You will notice where multiple wires exit your connection the Life Seal has completely sealed all the gaps.

Let cure and you have a truly watertight joint.

I took a pic of some samples but don,t know yet if I can upload it. It should be attached.

Note: If you want a neater appearance you can take a shrink tube just large enough to fit over your shrunk ends and shrink it down giving a very professional appearance. It doesn't matter if the Seal cures inside the connection though I'm pretty sure over time it will like in your tube. LOL.

You may already know this method but no-one on my dock had.