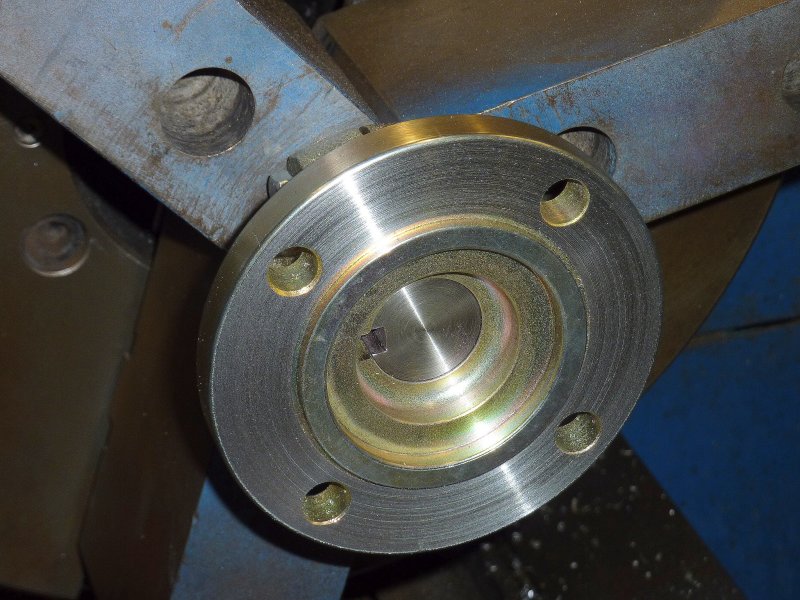

After installing my new strut and replacing my 4 motor mounts on our hunter 34 it appears that my shaft coupling is not round. We couldn't get the .000" - .003" that we needed to align the shaft. We put a dial gauge on it and found it to be out .010" and thus causing a wobble. Since we replaced all the above items I guess I should replace the coupling as well. My only problem is my coupling has the set screws at 12 and 6 the one that looks like it is a match for me shows the set screws at 12 and 3. Unless i am not looking at the correct coupling on our host parts house what should I do. Can I use the new off set set screws and drill a bore in the shaft or is this going to throw the shaft off because of the extra bore. The parts # that fits my coupling is #50mcy00410 (Buck Algonquin) it is a solid coupling.

Just for your info we did have the shaft checked and it is true and the transmission flange is also true.

Also since this is the coupling that is on the boat does it mean this is the correct one??? Any other h34 owners jump in here and let me know if I have the soliid or split coupling ??

Any help would be greatly appreciated,

Bub

Just for your info we did have the shaft checked and it is true and the transmission flange is also true.

Also since this is the coupling that is on the boat does it mean this is the correct one??? Any other h34 owners jump in here and let me know if I have the soliid or split coupling ??

Any help would be greatly appreciated,

Bub