We have been struggling with fuel issues since getting bad fuel running from Irma and Maria in 2017. The biggest problem is that Catalina did not install any inspection ports in the the fuel tank. To effectively clean the tank you need to access both sides of the baffle. Because the tank is installed under the sugar scoop you need to remove the tank to install clean outs. And why remove a 20 year old metal tank and re-install it, it might be better to get a new tank. That's a job better suited to when we are stopped to work again. So I'm stuck trying to figure out the best way to keep the motor going for the next year or two.

I have decided my best option is install a fuel polishing system I can use regularly. Especially under sail in rough conditions when stuff get stirred up.

Some of these modifications would be slightly different on a stock motor with the Facet lift pump and Racor R20 primary filter. But the concept would still work.

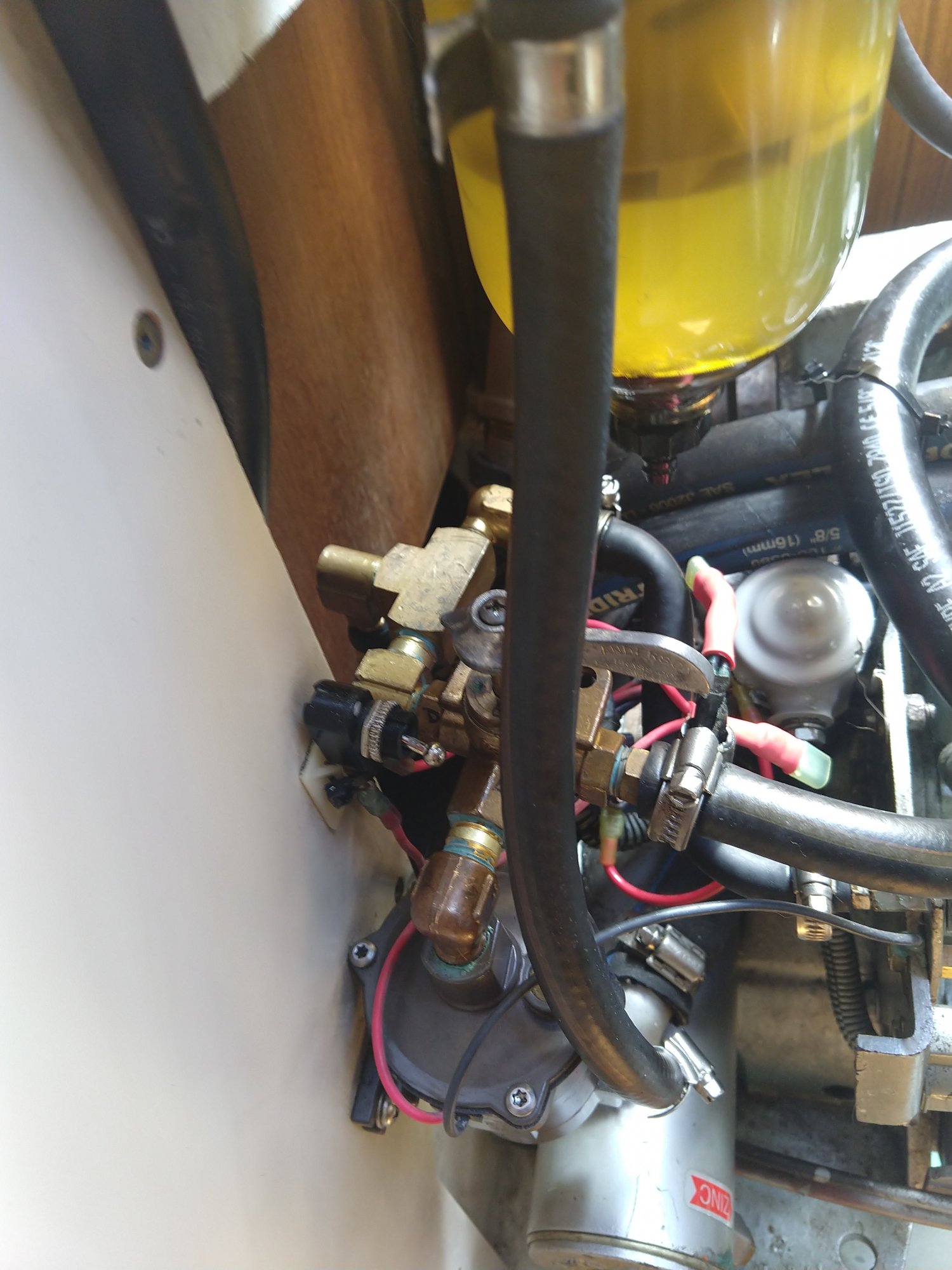

We have a Racor 500 as our primary fuel filter and a Walbro FRB-8 fuel pump mounted on the bulkhead. We run a 10 micron filter element in the Racor 500. The on engine fuel filter is a 2 micron. The Walbro isn't cheap but I had gotten frustrated with the poor quality of the cheap $35 automotive lift pumps. Since I was going to spend some real money on the fuel lift pump I researched options. The Walbro is larger than the factory Facet cube style pump. But it is also rebuildable in the field. A new Facet would have cost $80, the Walpro was $150. The Facet delivers fuel at about 7 gph, the Walbro varies on demand up to 40 gph. I did have the idea of building a polisher in mind when I made the decision to go with the Walbro.

To make the polisher I installed a three-way valve on the effluent of the Walbro pump. One direction goes to the supply for the on engine filter. The other direction is hard plumbed to a T fitting. One side of the T fitting goes to the return line to the tank. The other side of the T fitting goes to return coming from the engine.

When the three-way valve is turned to the engine fuel goes from the pump, to the one engine filter and then on to the high pressure pump and injectors. The return fuel goes to the T fitting and then on to the return line to the tank. When I select the polish position, the fuel goes from the pump directly to the return line to the tank.

The factory power setup for the pump is a quick disconnect tied to the solenoid switch. This is why you can push the key forward to activate the fuel pump as part of the self-priming system. On the pump side of the quick connect I added a second wire going to a switch. The other side of the switch is connected to my positive buss in the battery compartment with a fuse in line. If you turn on the switch, the fuel pump is activated. This is great for priming filters after changes. But it does active the solenoid switch and therefore activates the preheat circuit, you wouldn't want to leave this on for long polishing efforts. But disconnecting the quick connect eliminates the preheat circuit. You could also add a second switch to shut off the preheat circuit. I did take a unused heat shrink quick disconnect end, put some wire insulation in the crimp end, crimped and shrunk it. Now it works as a cap to eliminate accidentally groundings to the engine.

So to activate the polisher you turn the selector valve to polish, disconnect the quick connect and flip the switch. It can run for hours polishing the fuel and returning it to the tank. Not a perfect system but good.

The next step will be to add a 2 micron filter somewhere on the return line, likely with a bypass loop so that returned fuel from the engine isn't going through it.

Before I started building the system I shocked the tank with a double treatment of Biobor JF fuel treatment. I then ran the polisher for 20 hours in three sessions. The fuel looked clean and there was some definite build up in the bowl of the filter. I then switched to a 2 micron filter and ran it for another 8 hours (not advised for the Facet pump). Following that I did another treatment of the Biobor JF and a treatment of Starbrite Diesel Watersorb. I have now been running the polisher again for 2 hours. The fuel is now cloudy. Hopefully this clears up after several hours of polishing.

After the fuel clears up, I will change the filter back to a 10 micron and drain the sediment out of the bowl. Then it will be time to go for a sail in hopefully 6-8 foot seas to run the polisher while getting knocked around a bit.

I also need to break out the label maker and clean this up a bit.

Hopefully this works

I have decided my best option is install a fuel polishing system I can use regularly. Especially under sail in rough conditions when stuff get stirred up.

Some of these modifications would be slightly different on a stock motor with the Facet lift pump and Racor R20 primary filter. But the concept would still work.

We have a Racor 500 as our primary fuel filter and a Walbro FRB-8 fuel pump mounted on the bulkhead. We run a 10 micron filter element in the Racor 500. The on engine fuel filter is a 2 micron. The Walbro isn't cheap but I had gotten frustrated with the poor quality of the cheap $35 automotive lift pumps. Since I was going to spend some real money on the fuel lift pump I researched options. The Walbro is larger than the factory Facet cube style pump. But it is also rebuildable in the field. A new Facet would have cost $80, the Walpro was $150. The Facet delivers fuel at about 7 gph, the Walbro varies on demand up to 40 gph. I did have the idea of building a polisher in mind when I made the decision to go with the Walbro.

To make the polisher I installed a three-way valve on the effluent of the Walbro pump. One direction goes to the supply for the on engine filter. The other direction is hard plumbed to a T fitting. One side of the T fitting goes to the return line to the tank. The other side of the T fitting goes to return coming from the engine.

When the three-way valve is turned to the engine fuel goes from the pump, to the one engine filter and then on to the high pressure pump and injectors. The return fuel goes to the T fitting and then on to the return line to the tank. When I select the polish position, the fuel goes from the pump directly to the return line to the tank.

The factory power setup for the pump is a quick disconnect tied to the solenoid switch. This is why you can push the key forward to activate the fuel pump as part of the self-priming system. On the pump side of the quick connect I added a second wire going to a switch. The other side of the switch is connected to my positive buss in the battery compartment with a fuse in line. If you turn on the switch, the fuel pump is activated. This is great for priming filters after changes. But it does active the solenoid switch and therefore activates the preheat circuit, you wouldn't want to leave this on for long polishing efforts. But disconnecting the quick connect eliminates the preheat circuit. You could also add a second switch to shut off the preheat circuit. I did take a unused heat shrink quick disconnect end, put some wire insulation in the crimp end, crimped and shrunk it. Now it works as a cap to eliminate accidentally groundings to the engine.

So to activate the polisher you turn the selector valve to polish, disconnect the quick connect and flip the switch. It can run for hours polishing the fuel and returning it to the tank. Not a perfect system but good.

The next step will be to add a 2 micron filter somewhere on the return line, likely with a bypass loop so that returned fuel from the engine isn't going through it.

Before I started building the system I shocked the tank with a double treatment of Biobor JF fuel treatment. I then ran the polisher for 20 hours in three sessions. The fuel looked clean and there was some definite build up in the bowl of the filter. I then switched to a 2 micron filter and ran it for another 8 hours (not advised for the Facet pump). Following that I did another treatment of the Biobor JF and a treatment of Starbrite Diesel Watersorb. I have now been running the polisher again for 2 hours. The fuel is now cloudy. Hopefully this clears up after several hours of polishing.

After the fuel clears up, I will change the filter back to a 10 micron and drain the sediment out of the bowl. Then it will be time to go for a sail in hopefully 6-8 foot seas to run the polisher while getting knocked around a bit.

I also need to break out the label maker and clean this up a bit.

Hopefully this works