First post on the forum. Just closed on Fathom That a 1986 O'Day 31. Winter will be a long one but looking forward to exploring Lake Champlain with her over the next few years!

New O'Day owner.

- Thread starter peterandginny

- Start date

Most people that have O'Day's seem to really like them. I already miss the 25' I sold last year

Welcome, use the winter months to get to know your new O'Day and its systems!

I was not gainfully employed when I first bought my O'day 35. I therefore spent the first winter rebuilding most of the systems aboard. This became my Monday to Friday job.

What did the system rebuild include? Here is a partial list;

Much of what I did I have since re-done in a better way. For example, I added a PSS Dripless Shaft Seal in 2013. I have also changed the coolant type to Fleetguard ES Compleat (sic) because it was reported by Practical Sailor to be "better" than the no name coolant mix that was in there.

What did the system rebuild include? Here is a partial list;

- New SmartPlug shore power inlet

- Rebedded some stanchions

- Replaced the heat exchanger anode

- Replaced the coolant in the closed cooling system loop

- Moved and mounted the domestic hot water heater to a better location in the lazerette

- Troubleshooting and repair of the VacuFlush holding tank

- Repacked the propeller shaft gland

- I had the hatches rebuilt by Select Plastics, and I purchased screens and shades for them

- I replaced the inoperative electric bilge pump and the switch. I used a Rule Gold 2000 and an Ultimate Bilge Pump Switch, and these are still working today. (15 years!)

- I rebuilt the drop boards for the companionway out of 3/8" acrylic (should have used 1/2")

- I replaced the plastic tank vent fittings with new stainless steel tank vents

- I rebuilt the primary electrical system, and hinged the electrical panel so that I can access the back without removing screws

- I replaced the 51 Amp alternator with a 90 Amp alternator

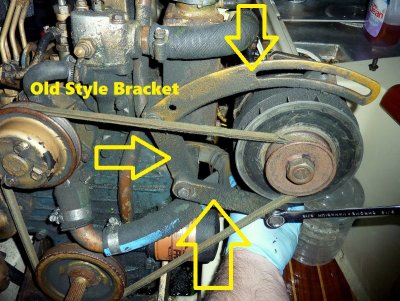

- I upgraded the alternator mounting bracket on the M25

- I built and installed new stainless steel hand rails to replace the worn old teak handrails.

- I rebuilt the Oberdorfer raw water pump

- I installed a 30A Galvanic Isolator

- I replaced the rubber throttle and shift levers with stainless steel ones

- I installed an electric fuel gauge (but didn't notice that the negative lead was tied to the bonding system of the boat thereby leading to my zincs dissolving after every 6 weeks

)

- I installed a Xantrex Echo Charge (today I would use an ACR)

- I rebuilt the Beckson Ports and their latches

- I added two cleats to the Genoa track - giving me needed mid-ship cleats

- I replaced the coolant pump on the M25

- I installed a new VHF radio

- I installed LED steaming and foredeck lights

- I installed a new engine thermostat

- I painted the bottom

Much of what I did I have since re-done in a better way. For example, I added a PSS Dripless Shaft Seal in 2013. I have also changed the coolant type to Fleetguard ES Compleat (sic) because it was reported by Practical Sailor to be "better" than the no name coolant mix that was in there.

That's a good, and long, list.

- I replaced the plastic tank vent fittings with new stainless steel tank vent

- I upgraded the alternator mounting bracket on the M25

Does your boat have plastic through hulls for the above the waterline holding tank, bilge pump and cockpit discharges?

Mine does and they have been on my list to swap out for bronze but I have not done that yet. I was wondering if others have done that or just lived with the plastic.

@peterandginny , if you have a Universal M-25 or M-18 the alternator bracket is important to check:

Yes, my boat has/had plastic above the waterline discharges for the following:That's a good, and long, list.

Does your boat have plastic through hulls for the above the waterline holding tank, bilge pump and cockpit discharges?

Mine does and they have been on my list to swap out for bronze but I have not done that yet. I was wondering if others have done that or just lived with the plastic.

@peterandginny , if you have a Universal M-25 or M-18 the alternator bracket is important to check:

- One 1-1/8" through hull for the electric bilge pump (labeled "Rule") - I replaced this with plastic through hull in 2011 - [edit] The UV damage to this through hull caused it to brake off when I touched it with my finger while I was polishing the hull for the first time. I fear to think of what would have happened if the boat were in the water at the time.

- Two 5/8" for propane lockers - replaced these with plastic in 2023

- One 3/4" discharge for the shower sump in the head - replaced with stainless steel in 2022

- Two 1-1/2" cockpit drains - replaced with plastic in 2023

- Two 1-1/2" cockpit drain discharge - replaced with stainless steel in 2023

- One 5/8 discharge for the sink in the head - replaced with plastic in 2023

Propane locker;

Cockpit drain and manual bilge pump discharge;

Last edited:

The holding tank discharge is below the waterline, and is a bronze through hull, connected to a bronze seacock.

Good info. Thanks.Yes, my boat has/had plastic above the waterline discharges for the following:

Sink & Shower discharge;

- One 1-1/8" through hull for the electric bilge pump (labeled "Rule") - I replaced this with plastic through hull in 2011 - [edit] The UV damage to this through hull caused it to brake off when I touched it with my finger while I was polishing the hull for the first time. I fear to think of what would have happened if the boat were in the water at the time.

- Two 5/8" for propane lockers - replaced these with plastic in 2023

- One 3/4" discharge for the shower sump in the head - replaced with stainless steel in 2022

- Two 1-1/2" cockpit drains - replaced with plastic in 2023

- Two 1-1/2" cockpit drain discharge - replaced with stainless steel in 2023

- One 5/8 discharge for the sink in the head - replaced with plastic in 2023

View attachment 234992

Propane locker;

View attachment 234993Cockpit drain and manual bilge pump discharge;