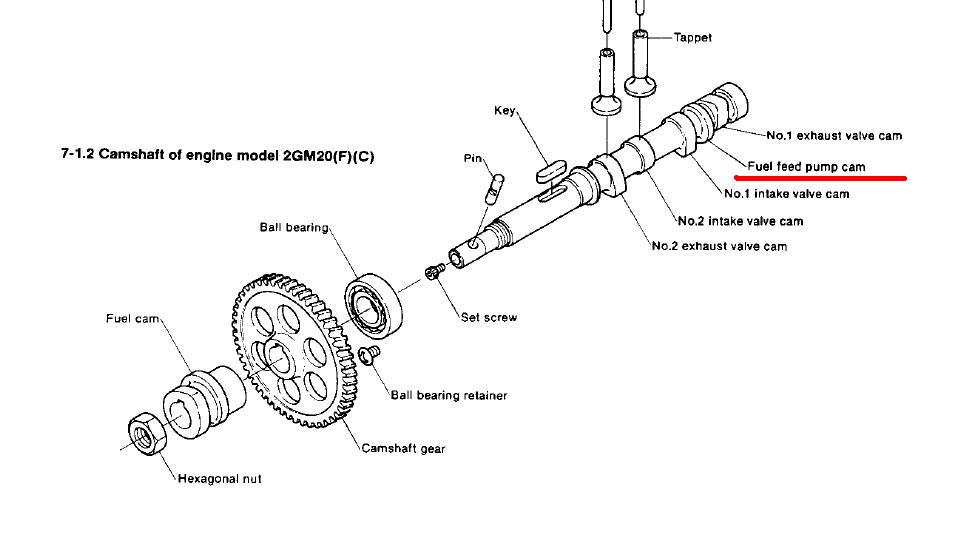

I recently had the pleasure of finding an external weeping fuel leak on the lift pump of my Yanmar 2GM20F. Now how much of a problem could it be to replace the lift pump ? With the engine location I have, bloody murder  . A few inches at best to see around the starboard side of the engine. The only way to see in beside the engine is with a mirror. Removing the pump was not bad but installing another pump is pretty much impossible. When you peer inside the pump hole and see that the lift pump cam is only about 1/4" wide, not much of a target and easy as spit to miss it when the pump cam rider goes in.

. A few inches at best to see around the starboard side of the engine. The only way to see in beside the engine is with a mirror. Removing the pump was not bad but installing another pump is pretty much impossible. When you peer inside the pump hole and see that the lift pump cam is only about 1/4" wide, not much of a target and easy as spit to miss it when the pump cam rider goes in.

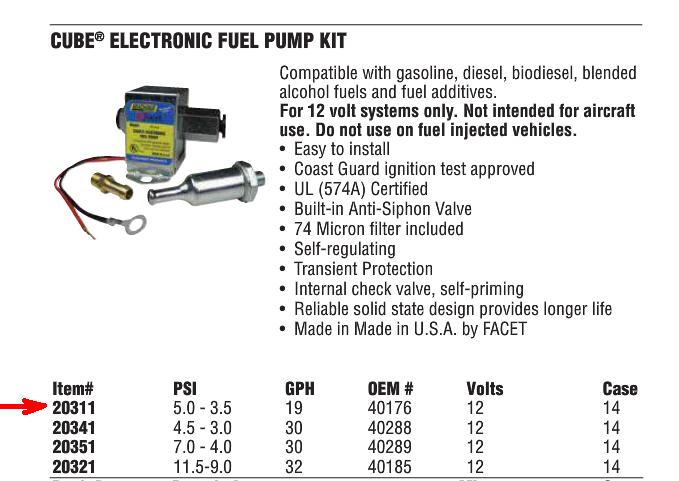

Rather than pulling the engine just to install the lift pump, I'll install an electric lift pump. The first question which comes to mind is the delivery pressure. Yanmar specs their mechanical pump at 1.422 PSI.

How important is it to match this pressure and will exceeding this by a few PSI cause any problems ? I'm looking at a Seachoice CUBE (USCG ignition approved) which is 3.5 PSI.

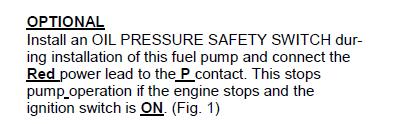

Also, is the pump wired across the ignition switch or across the oil pressure switch ? The Seachoice also seems to be concerned about leaving the ignition switch on while the engine is not running. Is this a concern for a diesel ?

Thanks as always for the suggestions.

Rather than pulling the engine just to install the lift pump, I'll install an electric lift pump. The first question which comes to mind is the delivery pressure. Yanmar specs their mechanical pump at 1.422 PSI.

How important is it to match this pressure and will exceeding this by a few PSI cause any problems ? I'm looking at a Seachoice CUBE (USCG ignition approved) which is 3.5 PSI.

Also, is the pump wired across the ignition switch or across the oil pressure switch ? The Seachoice also seems to be concerned about leaving the ignition switch on while the engine is not running. Is this a concern for a diesel ?

Thanks as always for the suggestions.