Hi all,

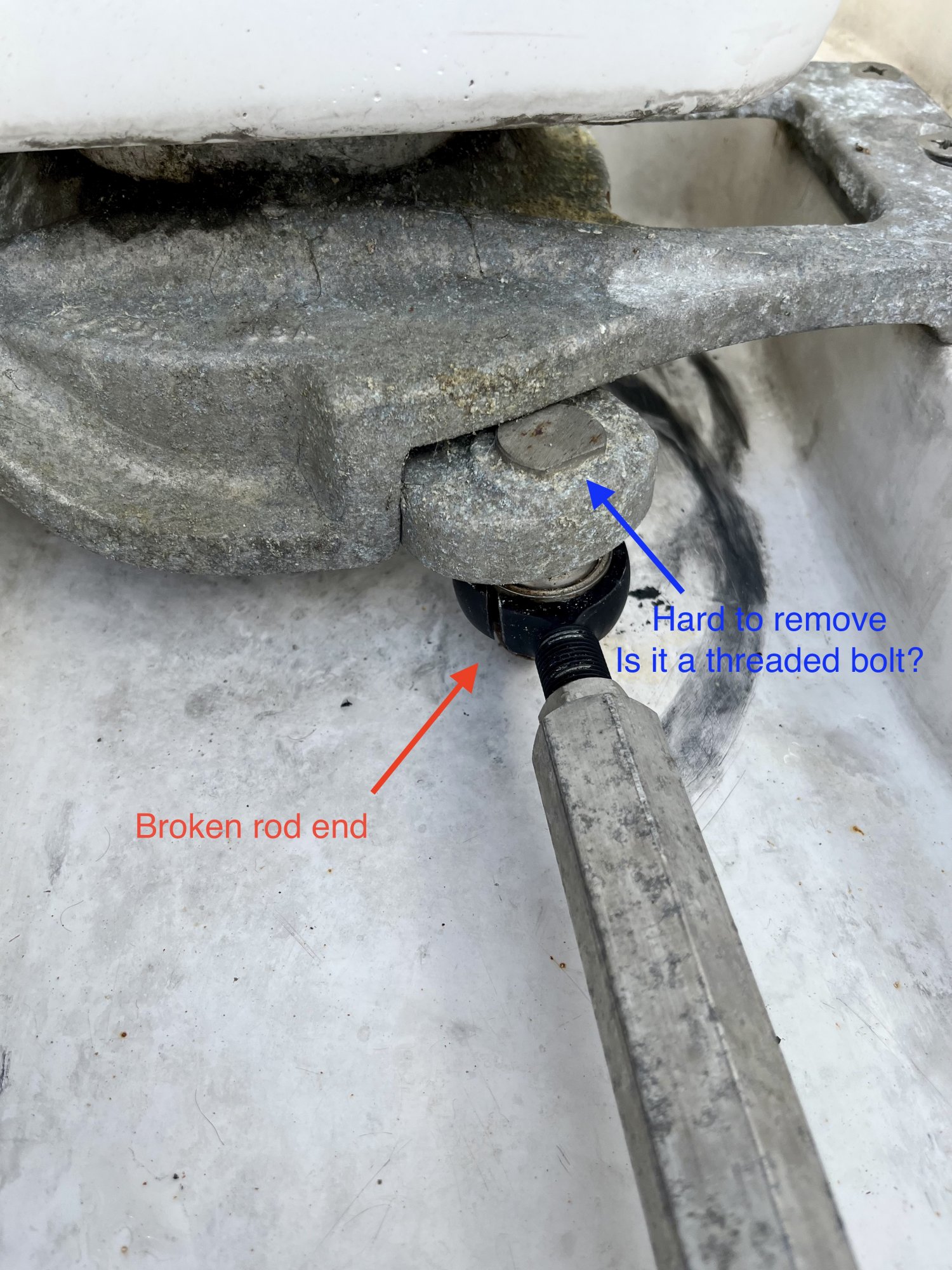

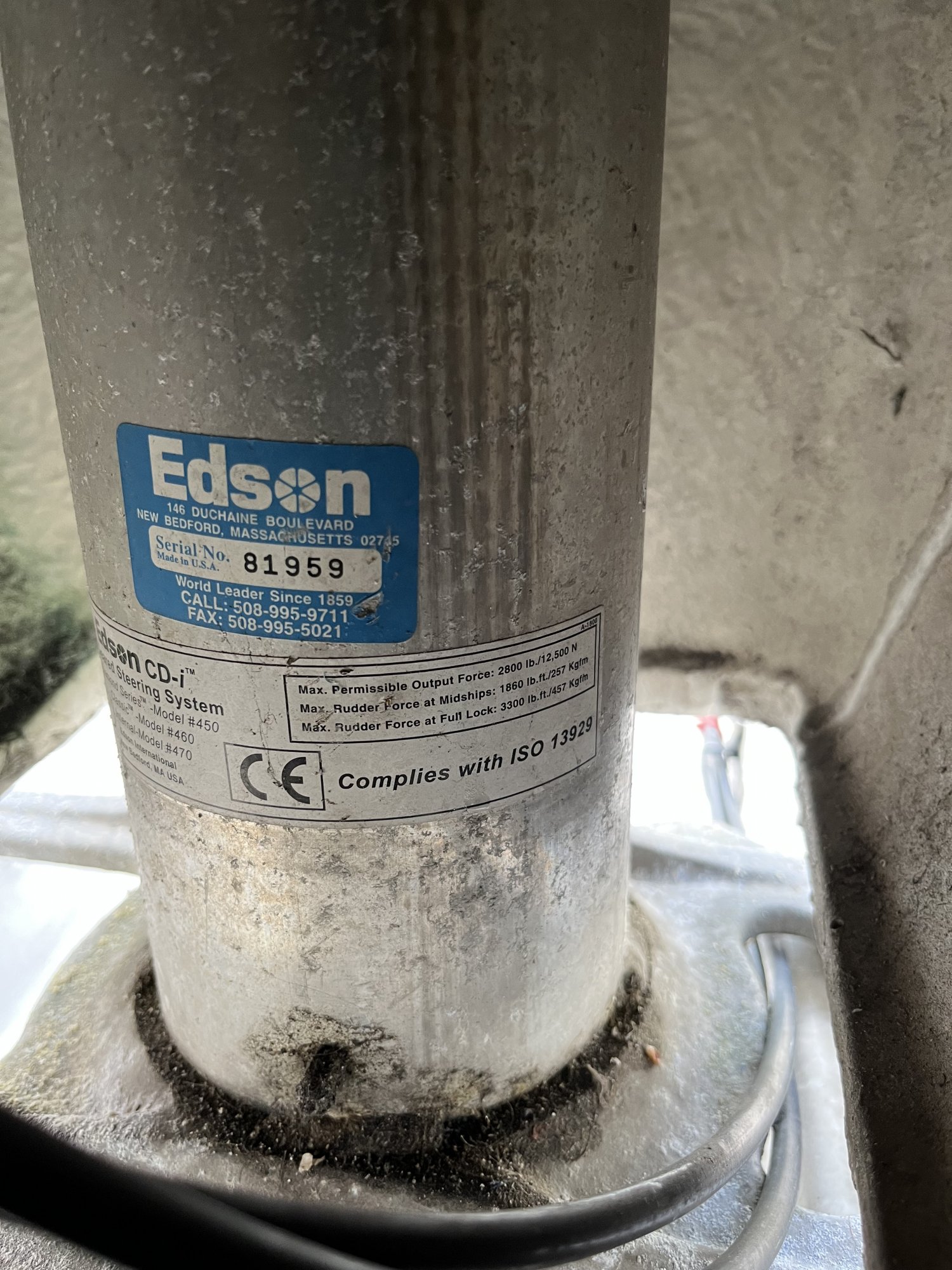

Wondering if anyone has had a similar experience with their steering. Our boat has pedestal steering with a rod to the rudder (as pictured). One of the rod ends broke causing the arm to fall. We were fortunately able to continue to steer as the broken rod end was still around the nut, but I'm having trouble removing the arm and ends to replace (I have replacement parts from Edson).

The issue for me is getting the bolt out. It's been suggested that the dissimilar metals are hard to remove (probably steel into aluminum) and some PB and heat might work. Anyone had a similar issue?

Cheers!

Kev

Wondering if anyone has had a similar experience with their steering. Our boat has pedestal steering with a rod to the rudder (as pictured). One of the rod ends broke causing the arm to fall. We were fortunately able to continue to steer as the broken rod end was still around the nut, but I'm having trouble removing the arm and ends to replace (I have replacement parts from Edson).

The issue for me is getting the bolt out. It's been suggested that the dissimilar metals are hard to remove (probably steel into aluminum) and some PB and heat might work. Anyone had a similar issue?

Cheers!

Kev