How do people mount their anchor on bow on smaller O'days (mine is a 19')

- Thread starter Beachdog2

- Start date

This O'Day 19 sailor found a solution in this article with the following requirements: 1)have thew anchor easily accessible, 2) anchor cannot get in the way of anything, 3) anchor must be secure and 4) rode must be well ventilated.

www.mariner1922.com

www.mariner1922.com

Anchor Stowage — O'Day Mariner #1922, "Orion"

Where it should be is a discussion. I keep mine on the bow pulpit. The problem is, the chain and anchor bump the top sides on the way up. I'm still struggling with that. A have two friends who keep the anchor at the stern, while the anchor line is attached at the bow. That solves the bumping problem. Plus he has the option of tethering it to the stern. The boat doesn't hunt back and forth in that mode. Also, he never goes to the bow. I have an O'Day 222 and the others are a Cat 22 and O'Day Mariner. Where should the anchor be? Where it best suits you.

If it is an O'Day 19 you own, and not an O'Day 192, I know there is a chamber behind the V-berth that you can access by cutting a access opening in the panel separating the V-berth from the chamber as I once owned an O'Day 19. From another forum you submitted an inquiry to, my understanding is that you do not have a bow pulpit on your boat. Although I did add a bow pulpit, I used a circle cutter to cut an opening (inspection port) into the aforementioned panel at forward end of V-berth and installed a detachable round 5 inch plastic deck plate (available at any marine store) the cover of which screwed into the plate. There is a fairly substantial area in this forward bow area for storage of an anchor rode. I than cut another opening on deck and installed a stainless or chrome plated chain pipe with hinged cap (also available at any marine supply store) which allowed me to pull my anchor rode up out of the compartment I had gained access to from the V-berth. This arrangement was very easy to install and provided a neat way to store my anchor rode and have it readily available to attach to anchor. This of course does not solve your problem of securing an anchor at the bow as you lack a bow pulpit. However, you could possibly solve that by installation of an anchor roller if your roller furling system does not present a problem. In any event, you will have an out of the way means of safely storing your anchor rode. The O'Day 192 may also have the separate bow chamber, but I am not familiar with that model.

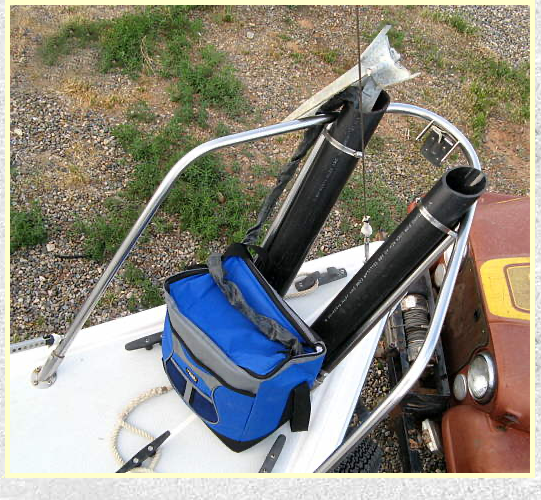

Here's a neat solution from the MacGregor site:

These are jut PVC or ABS plastic pipe held in place with hose clamps. I also found a narrow bow roller that I use now on my O'Day 222 that has worked out great.

Others anchor from the cockpit by attaching the rode to a separate line that goes from the cockpit, to a pulley on the bow pulpit, and then back to the cockpit (outside any stanchions if you have any) with a carabiner on the end. The anchor is stored somewhere accessible to the cockpit, and when ready to use, the carabiner is clipped around the rode, the anchor lowered. Once the anchor is on the bottom, the non carabiner end is pulled, which takes the rode to the bow. The separate line is secured in the cockpit, as well as the rode, then the sailor can go forward and secure the rode to a cleat at the bow. If it's just a short stay in fair weather, one doesn't even have to cleat the rode at the bow.

These are jut PVC or ABS plastic pipe held in place with hose clamps. I also found a narrow bow roller that I use now on my O'Day 222 that has worked out great.

Others anchor from the cockpit by attaching the rode to a separate line that goes from the cockpit, to a pulley on the bow pulpit, and then back to the cockpit (outside any stanchions if you have any) with a carabiner on the end. The anchor is stored somewhere accessible to the cockpit, and when ready to use, the carabiner is clipped around the rode, the anchor lowered. Once the anchor is on the bottom, the non carabiner end is pulled, which takes the rode to the bow. The separate line is secured in the cockpit, as well as the rode, then the sailor can go forward and secure the rode to a cleat at the bow. If it's just a short stay in fair weather, one doesn't even have to cleat the rode at the bow.

Ya don't. For smaller boats, you don't want unnecessary weight at the ends. Also, for smaller boats, it's not always as easy to go up on the foredeck to deal with the anchor. I heard years ago about small dinghy sailors keeping the anchor in a bucket. Having only grown up with Danforth style anchors, I didn't understand how you could get a big enough bucket to keep a Danforth in! Then I learned about alternative styles of anchors, especially the "next generation" anchor such as Rocna, Manson Supreme, and Mantus. I started off with a small Bruce knockoff (Lewmar Claw) for my 14' dinghy, and I was able to fit the nylon warp in the bucket, and the claw on top. I've since moved on from that to a bigger Manson Supreme (which is actually too big for my anchoring conditions at the lake) and a smaller, disassembleable Mantus Dinghy anchor for a lunch hook.

I keep the warp and @20' of chain in a rubber feed bucket from Tractor Supply down in my lazarette. When I get into the cove where I want to anchor, I bring the bucket up into the cockpit, and feed the anchor over the stern. This allows me to steer (under sail) or steer and control the motor, while easily handling the anchor. I can also set the anchor. Once everything is set, I walk the bucket up to the foredeck and cleat it off, leaving the bucket with extra warp on the deck. (I also tie off the warp to the bucket handle, so it doesn't disappear over the side as easily!)

When I'm ready to weigh anchor, I'll start up the motor and let it idle, or hoist the main and let it slat. I go up to the foredeck and usually haul the anchor, putting the warp and chain right into the bucket in a loose flake that runs out with no problem. I then carry it back to the cockpit. This is much easier because things are generally pretty calm weighing the anchor.

If I wanted to weigh anchor from the cockpit in a reverse of setting the anchor, I could tie a length of extra line around the warp about 10 or 15 feet from where I want to cleat off, using a rolling hitch. I can loosely cleat this at the stern cleat, and when I'm ready to weigh anchor, I could pull in on this line, pulling the warp back to me at the cockpit, and proceed to bring up all the rest of the line. I'd probably wind up pulling the boat backwards toward the anchor. (Note that I haven't felt the need to do this ever, but I've already thought thorough how I would.) I've heard that some people do this with the warp through a welded ring. But you'd still need to let the ring fall down the tight(ish) warp some before you could start pulling it back towards the cockpit. One of the benefits of doing this with a rolling hitch line around the warp, is that you could cleat it off adjusting the angle of the boat to deal with current that runs differently to the wind, or maybe to help prevent the boat sailing on anchor so much. My boat sails at anchor way more than I expect her to, so if I were really anchoring out for any length of time, I think I'd have to make up a riding sail of some form to calm it down.

One other reason to not keep a Danforth style anchor hanging in those brackets from the pulpit is that it is much more fiddly to deploy it quickly in a situation where you NEED to set an anchor. An anchor in a bucket with free flowing warp flaked in (not coiled and tied up) can be ready to go in about a minute from my boat.

I keep the warp and @20' of chain in a rubber feed bucket from Tractor Supply down in my lazarette. When I get into the cove where I want to anchor, I bring the bucket up into the cockpit, and feed the anchor over the stern. This allows me to steer (under sail) or steer and control the motor, while easily handling the anchor. I can also set the anchor. Once everything is set, I walk the bucket up to the foredeck and cleat it off, leaving the bucket with extra warp on the deck. (I also tie off the warp to the bucket handle, so it doesn't disappear over the side as easily!)

When I'm ready to weigh anchor, I'll start up the motor and let it idle, or hoist the main and let it slat. I go up to the foredeck and usually haul the anchor, putting the warp and chain right into the bucket in a loose flake that runs out with no problem. I then carry it back to the cockpit. This is much easier because things are generally pretty calm weighing the anchor.

If I wanted to weigh anchor from the cockpit in a reverse of setting the anchor, I could tie a length of extra line around the warp about 10 or 15 feet from where I want to cleat off, using a rolling hitch. I can loosely cleat this at the stern cleat, and when I'm ready to weigh anchor, I could pull in on this line, pulling the warp back to me at the cockpit, and proceed to bring up all the rest of the line. I'd probably wind up pulling the boat backwards toward the anchor. (Note that I haven't felt the need to do this ever, but I've already thought thorough how I would.) I've heard that some people do this with the warp through a welded ring. But you'd still need to let the ring fall down the tight(ish) warp some before you could start pulling it back towards the cockpit. One of the benefits of doing this with a rolling hitch line around the warp, is that you could cleat it off adjusting the angle of the boat to deal with current that runs differently to the wind, or maybe to help prevent the boat sailing on anchor so much. My boat sails at anchor way more than I expect her to, so if I were really anchoring out for any length of time, I think I'd have to make up a riding sail of some form to calm it down.

One other reason to not keep a Danforth style anchor hanging in those brackets from the pulpit is that it is much more fiddly to deploy it quickly in a situation where you NEED to set an anchor. An anchor in a bucket with free flowing warp flaked in (not coiled and tied up) can be ready to go in about a minute from my boat.

I think that it is an interesting solution, but without a pulpit, I don't think I will follow that route. I like the idea mentioned by someone else to just keep it ready in the front locker but have the line connected to the front of the boat so I can just toss it out if needed. Thanks for the details.... maybe sometime in the future.If it is an O'Day 19 you own, and not an O'Day 192, I know there is a chamber behind the V-berth that you can access by cutting a access opening in the panel separating the V-berth from the chamber as I once owned an O'Day 19. From another forum you submitted an inquiry to, my understanding is that you do not have a bow pulpit on your boat. Although I did add a bow pulpit, I used a circle cutter to cut an opening (inspection port) into the aforementioned panel at forward end of V-berth and installed a detachable round 5 inch plastic deck plate (available at any marine store) the cover of which screwed into the plate. There is a fairly substantial area in this forward bow area for storage of an anchor rode. I than cut another opening on deck and installed a stainless or chrome plated chain pipe with hinged cap (also available at any marine supply store) which allowed me to pull my anchor rode up out of the compartment I had gained access to from the V-berth. This arrangement was very easy to install and provided a neat way to store my anchor rode and have it readily available to attach to anchor. This of course does not solve your problem of securing an anchor at the bow as you lack a bow pulpit. However, you could possibly solve that by installation of an anchor roller if your roller furling system does not present a problem. In any event, you will have an out of the way means of safely storing your anchor rode. The O'Day 192 may also have the separate bow chamber, but I am not familiar with that model.

What is the warp?Ya don't. For smaller boats, you don't want unnecessary weight at the ends. Also, for smaller boats, it's not always as easy to go up on the foredeck to deal with the anchor. I heard years ago about small dinghy sailors keeping the anchor in a bucket. Having only grown up with Danforth style anchors, I didn't understand how you could get a big enough bucket to keep a Danforth in! Then I learned about alternative styles of anchors, especially the "next generation" anchor such as Rocna, Manson Supreme, and Mantus. I started off with a small Bruce knockoff (Lewmar Claw) for my 14' dinghy, and I was able to fit the nylon warp in the bucket, and the claw on top. I've since moved on from that to a bigger Manson Supreme (which is actually too big for my anchoring conditions at the lake) and a smaller, disassembleable Mantus Dinghy anchor for a lunch hook.

I keep the warp and @20' of chain in a rubber feed bucket from Tractor Supply down in my lazarette. When I get into the cove where I want to anchor, I bring the bucket up into the cockpit, and feed the anchor over the stern. This allows me to steer (under sail) or steer and control the motor, while easily handling the anchor. I can also set the anchor. Once everything is set, I walk the bucket up to the foredeck and cleat it off, leaving the bucket with extra warp on the deck. (I also tie off the warp to the bucket handle, so it doesn't disappear over the side as easily!)

When I'm ready to weigh anchor, I'll start up the motor and let it idle, or hoist the main and let it slat. I go up to the foredeck and usually haul the anchor, putting the warp and chain right into the bucket in a loose flake that runs out with no problem. I then carry it back to the cockpit. This is much easier because things are generally pretty calm weighing the anchor.

If I wanted to weigh anchor from the cockpit in a reverse of setting the anchor, I could tie a length of extra line around the warp about 10 or 15 feet from where I want to cleat off, using a rolling hitch. I can loosely cleat this at the stern cleat, and when I'm ready to weigh anchor, I could pull in on this line, pulling the warp back to me at the cockpit, and proceed to bring up all the rest of the line. I'd probably wind up pulling the boat backwards toward the anchor. (Note that I haven't felt the need to do this ever, but I've already thought thorough how I would.) I've heard that some people do this with the warp through a welded ring. But you'd still need to let the ring fall down the tight(ish) warp some before you could start pulling it back towards the cockpit. One of the benefits of doing this with a rolling hitch line around the warp, is that you could cleat it off adjusting the angle of the boat to deal with current that runs differently to the wind, or maybe to help prevent the boat sailing on anchor so much. My boat sails at anchor way more than I expect her to, so if I were really anchoring out for any length of time, I think I'd have to make up a riding sail of some form to calm it down.

One other reason to not keep a Danforth style anchor hanging in those brackets from the pulpit is that it is much more fiddly to deploy it quickly in a situation where you NEED to set an anchor. An anchor in a bucket with free flowing warp flaked in (not coiled and tied up) can be ready to go in about a minute from my boat.

Also known as the anchor line or rode.What is the warp?

Thank you, I knew it as the rode.Also known as the anchor line or rode.

Kappykaplan's got it. Warp=rode. Maybe warp is more British than rode? One of my first boats was a British GP14 and I spent A LOT of time on those forums years ago....What is the warp?