Hi Maine. A couple seasons ago, a poorly bundled 12 gauge wire came loose above my engine and hit the only hot spot on the exhaust. The insulation melted, and we had a dead short.

The wires insulation ignited and burned from the alternator back to the engine panel. Seeing smoke, I turned the ignition switch off which stopped the burning. We were lucky as the wire caught nothing else on fire.

This season I had a bad connection in the ignition circuit and replaced some wiring(my boat is 51 years old). In doing that, I decided to install an inline fuse to attempt protecting the wires in the ignition circuit.

It's a pretty simple circuit; Short cable from starting battery to ON/OFF switch. Short cable to starter terminal. 10 gauge wire on same starter terminal goes to glow plug solenoid, then to ignition panel Amp gauge. Then the 10 ga. goes out of the Amp meter to a post on the dual output alternator. Off the inlet to the Amp gauge, a 12 gauge wire feeds the ignition panel guages, switches, via the keyed ignition switch.

I cut an inline fuse holder into the 10 gauge line just after the starter post and used a 30 amp fuse. That worked fine until I hit the glow plug solenoid. In about 5 seconds, the load from the glow plugs blows the 30 amp. So I took the inline fuse holder out and am now back to square one. But all the wires are safely bundled. Still, I would like to protect those wires after that experience.

I know about the battery terminal fuses now available and will install one(I'm not worried about the battery cables, short and enclosed in safe spaces. But I don't see how a 300 amp fuse is going to protect that 10 gauge wire which I presume was installed for the higher amperage of the glow plugs and alternator.

Then the remaining circuits off the ignition panel are all 12 gauge, including the wire(power to alternator from a switch in my panel) that once caused the fire due to a dead short.

I can't see the 300 amp fuse protected those down stream wires. Maybe it will?

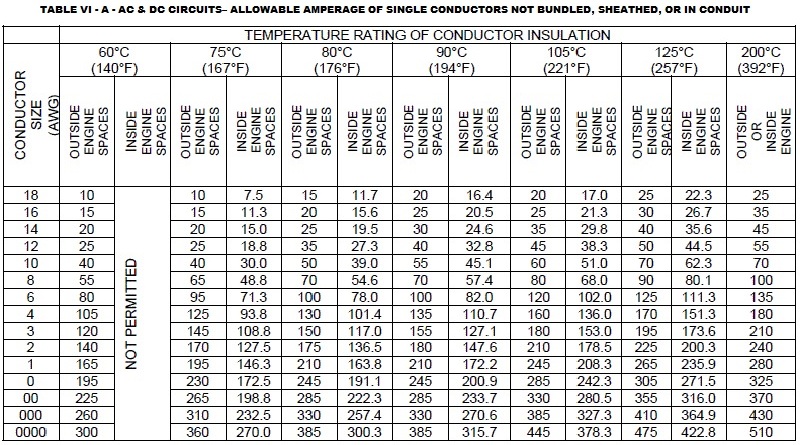

Or is the only solution to fuse each wire size as it steps down? It seems counter intuitive(I have been wiring houses for decades as a design builder)to be over sizing fuses to wire size, especially if the glow plugs amperage exceeds the 30 amps a 10 gauge wire is safely rated for.

Thanks.

The wires insulation ignited and burned from the alternator back to the engine panel. Seeing smoke, I turned the ignition switch off which stopped the burning. We were lucky as the wire caught nothing else on fire.

This season I had a bad connection in the ignition circuit and replaced some wiring(my boat is 51 years old). In doing that, I decided to install an inline fuse to attempt protecting the wires in the ignition circuit.

It's a pretty simple circuit; Short cable from starting battery to ON/OFF switch. Short cable to starter terminal. 10 gauge wire on same starter terminal goes to glow plug solenoid, then to ignition panel Amp gauge. Then the 10 ga. goes out of the Amp meter to a post on the dual output alternator. Off the inlet to the Amp gauge, a 12 gauge wire feeds the ignition panel guages, switches, via the keyed ignition switch.

I cut an inline fuse holder into the 10 gauge line just after the starter post and used a 30 amp fuse. That worked fine until I hit the glow plug solenoid. In about 5 seconds, the load from the glow plugs blows the 30 amp. So I took the inline fuse holder out and am now back to square one. But all the wires are safely bundled. Still, I would like to protect those wires after that experience.

I know about the battery terminal fuses now available and will install one(I'm not worried about the battery cables, short and enclosed in safe spaces. But I don't see how a 300 amp fuse is going to protect that 10 gauge wire which I presume was installed for the higher amperage of the glow plugs and alternator.

Then the remaining circuits off the ignition panel are all 12 gauge, including the wire(power to alternator from a switch in my panel) that once caused the fire due to a dead short.

I can't see the 300 amp fuse protected those down stream wires. Maybe it will?

Or is the only solution to fuse each wire size as it steps down? It seems counter intuitive(I have been wiring houses for decades as a design builder)to be over sizing fuses to wire size, especially if the glow plugs amperage exceeds the 30 amps a 10 gauge wire is safely rated for.

Thanks.