I've been sailing about a year and I purchased a new boat in May. I recently realized it is equipped with the EZ Glide system, but the previous owner wasn't using it and it wasn't rigged. I would like to start using it as it is an awesome upgrade! Here are some pics.

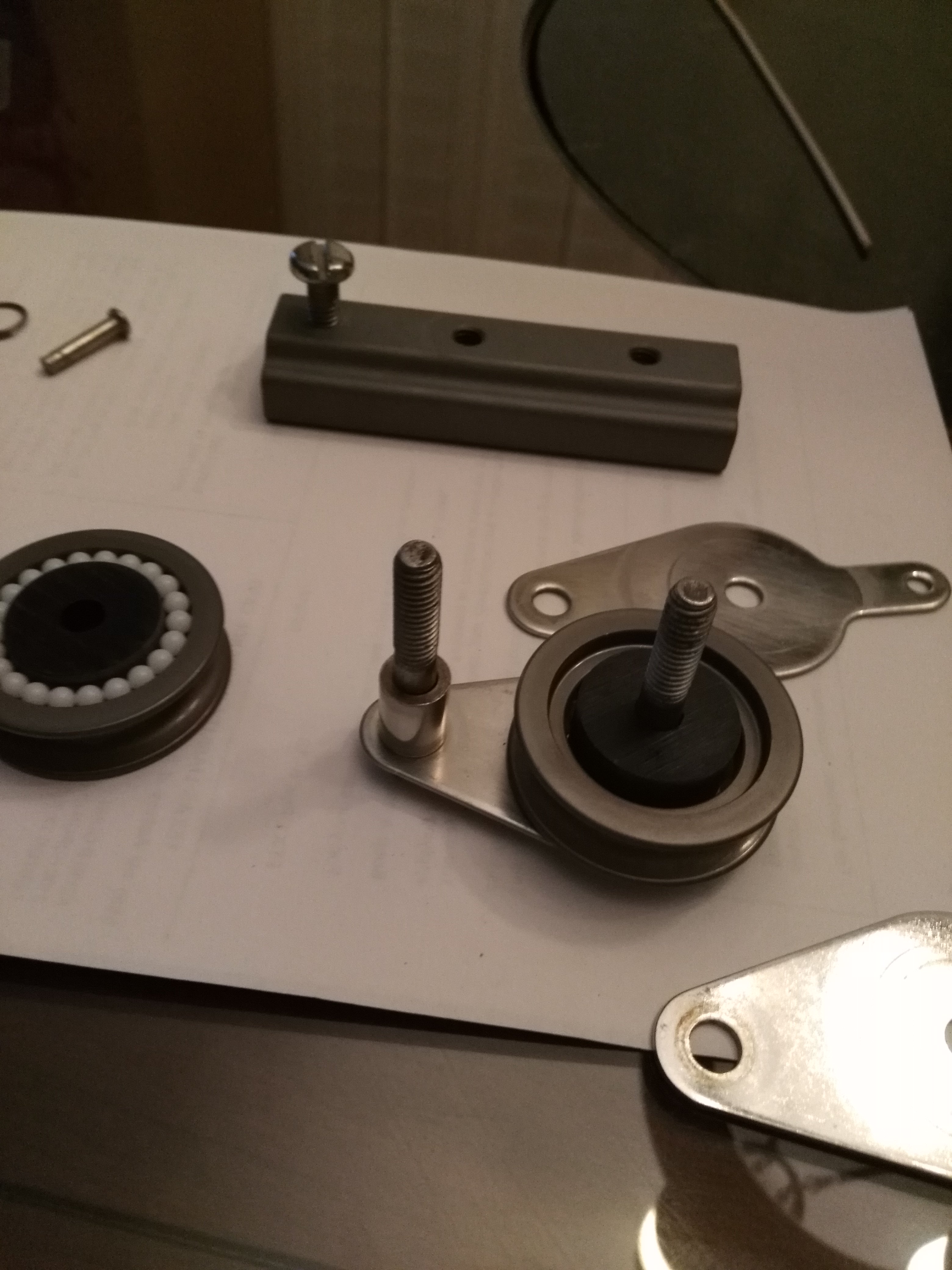

Forward double block with becket

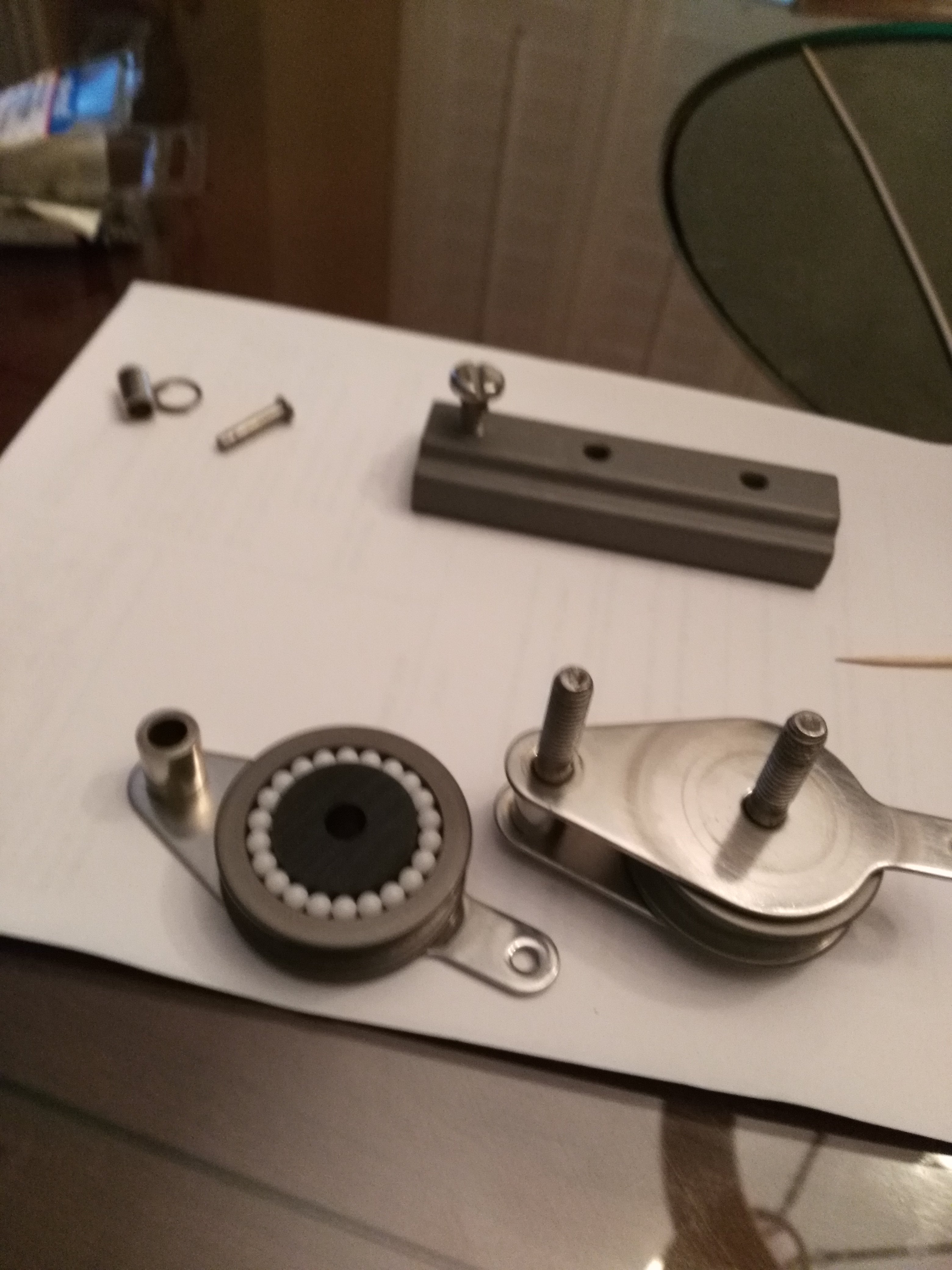

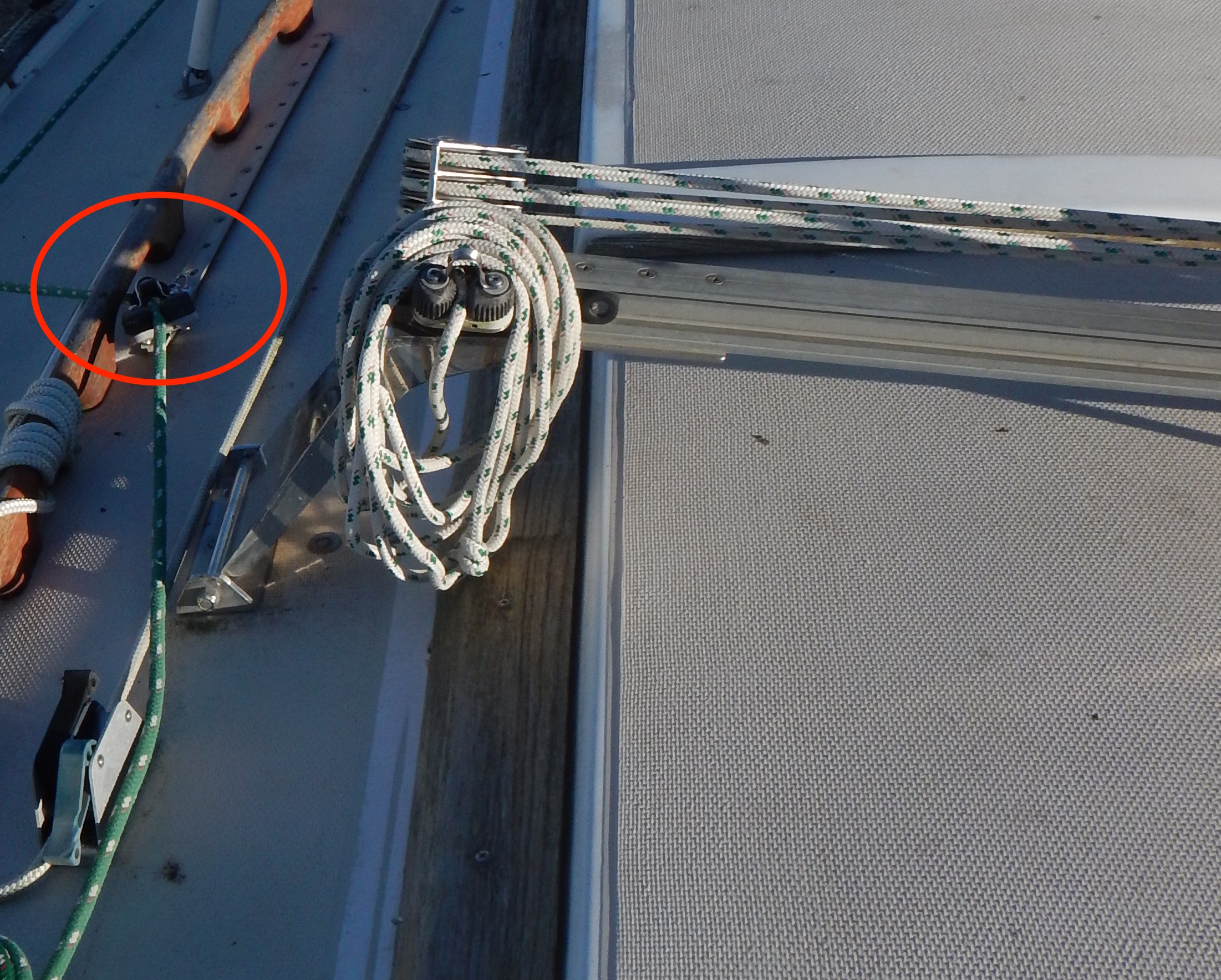

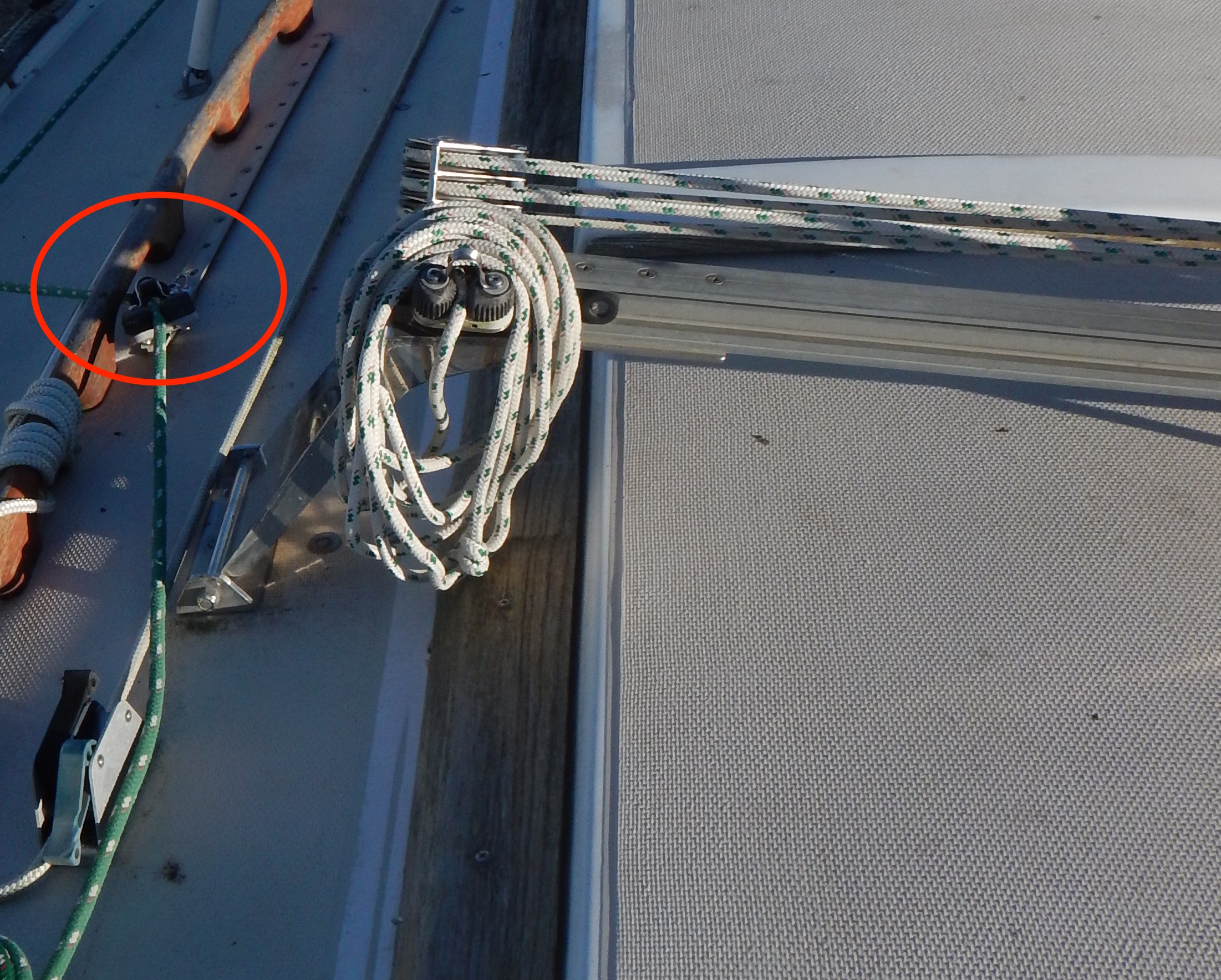

Car with standup block. Also another car block attached which I'm guessing is to guide the loaded sheet around the stanchion to avoid chafe. This will be an issue for the EZ Glide control line too.

Sheet goes aft to a turning car identical to the one behind the standup car, then up to the winch.

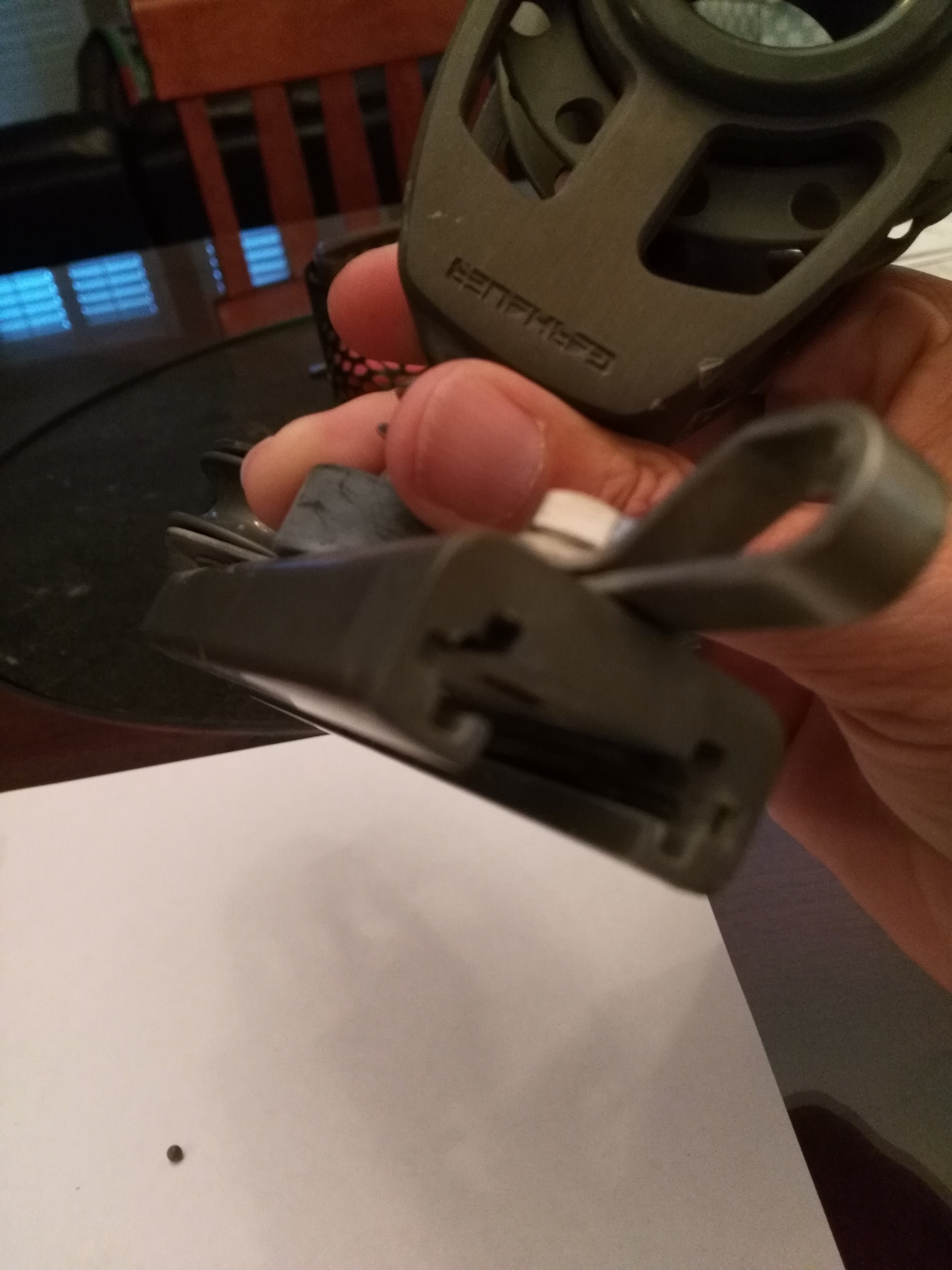

Finally, the optional fairlead and cam cleat was being used on cabin top tracks with the furling line (I immediately stopped using it for this purpose because the friction was making life unbearable).

I called Garhauer for setup and reeving diagrams but got lost on hold and transferred around. Maybe my vocabulary isn't strong enough to describe the boat jewelry well enough. Also, they don't have a great way to share visual evidence effectively. Either way, I didn't get a satisfactory answer to my call. So the questions are:

1. Control line sizing and reaving, what works best? I've read 7/16th. Seems hefty. Can I get by with 1/4" or 3/8". I can't find a diagram for reeving the control line i.e. tie line to forward double block becket, aft to stand up car, back forward to top or bottom sheave??, etc. etc.

2. The two swivel turning block cars seem to be used to guide the sheet around the stanchions. Is this common? Is there a better way? Seems to add a lot of friction..

3. Lube: Is PTFE spray on the track the best approach?

Thanks,

KBG

Forward double block with becket

Car with standup block. Also another car block attached which I'm guessing is to guide the loaded sheet around the stanchion to avoid chafe. This will be an issue for the EZ Glide control line too.

Sheet goes aft to a turning car identical to the one behind the standup car, then up to the winch.

Finally, the optional fairlead and cam cleat was being used on cabin top tracks with the furling line (I immediately stopped using it for this purpose because the friction was making life unbearable).

I called Garhauer for setup and reeving diagrams but got lost on hold and transferred around. Maybe my vocabulary isn't strong enough to describe the boat jewelry well enough. Also, they don't have a great way to share visual evidence effectively. Either way, I didn't get a satisfactory answer to my call. So the questions are:

1. Control line sizing and reaving, what works best? I've read 7/16th. Seems hefty. Can I get by with 1/4" or 3/8". I can't find a diagram for reeving the control line i.e. tie line to forward double block becket, aft to stand up car, back forward to top or bottom sheave??, etc. etc.

2. The two swivel turning block cars seem to be used to guide the sheet around the stanchions. Is this common? Is there a better way? Seems to add a lot of friction..

3. Lube: Is PTFE spray on the track the best approach?

Thanks,

KBG

Last edited: