We took delivery of our boat three yrs ago this Feb. It's a 1979 vintage. The VERY first thing I did was to open all tanks (fuel and water) and clean them out and polish the fuel (Al tanks). We Installed access plates on all tanks at the time. The fuel tank was clean when we closed it up and the water tanks were sorta clean as there was a lot of mineral stuff stuck to the sides etc. We had a leak on one water tank last winter and had to replace. We decided to replace the the other water tank and also the fuel tank as other S2 owners are reporting issues and we want piece of mind and not wanting to deal with such after I retire in April (We're going north). I emptied the fuel tank today and after three years, there was a lot of crap settled on the bottom of the tank. Nothing growing on the sides etc. The tank itself was really clean. I treated all fuel with Stanadyne. I expected some "stuff" but what I found was really surprising. All fuel that I have purchased has been from major fuel suppliers etc. I'm going to start filtering fuel that I take onboard. This also tells me that I need to open the tank up every few years and clean it out. My new tank will definately have an access plate upon fabrication. There have been a few threads on fuel tanks and people seem to be reluctant to opening a tank putting an access plate in the tank. DO IT!!!! Before you are forced to do it.......

Diesel Tank crap

- Thread starter Mark Maulden

- Start date

Mark, as a "regular' here, you may be aware of the fact that some of us haven't found the need to do so based on the condition of fuel we "see" through our fuel filters. Not the same for everyone.

Your boat, your choice.

Your boat, your choice.

Mark,

One thing to think of is the quality of the diesel fuel you use.

I NEVER fill up at a fuel dock. I get my fuel from a gas station & jerry can it to my boat.

The fuel I use is as clear as water, close to jet-A quality. The major brand stations like Sunoco carries good fuel, as it doesn't sit for long periods.

I also installed an access hatch in my fuel tank & check it every 3 years. I do find that my tank bottom is pretty clean. One secret is to use your fuel, rather than let it sit for long periods of time.

Take in consideration the quality, age, effects of condensation & bugs living-n-dying, all of which adds to crud buildup & filter clogging. I can't remember the last time my filters clogged, ya know like when coming into a pass with current against etc. These are just what I have witnessed.

A friend of mine with an Ericson 34 had problems with his aluminum tanks leaking. He had replacement tanks fabricated & when installing them, a year later had the same leaks. I did tell him that I would not reconnect the bonding wire to the tanks. He did, needed new tanks, a year later. This time he didn't connect the ugly green wire. He now uses an alligator clip on the bonding wire to the tank only when he is fueling. By the way, the tanks all had holes in the mid bottom areas. Where was your leak?

He is in a closed bayou with a lot of liv-a-boards all hooked up to electrical systems, hence the stray current. Some will disagree with this but that's OK, as I no longer have issues with electrolysis & aluminum.

CR

CR

One thing to think of is the quality of the diesel fuel you use.

I NEVER fill up at a fuel dock. I get my fuel from a gas station & jerry can it to my boat.

The fuel I use is as clear as water, close to jet-A quality. The major brand stations like Sunoco carries good fuel, as it doesn't sit for long periods.

I also installed an access hatch in my fuel tank & check it every 3 years. I do find that my tank bottom is pretty clean. One secret is to use your fuel, rather than let it sit for long periods of time.

Take in consideration the quality, age, effects of condensation & bugs living-n-dying, all of which adds to crud buildup & filter clogging. I can't remember the last time my filters clogged, ya know like when coming into a pass with current against etc. These are just what I have witnessed.

A friend of mine with an Ericson 34 had problems with his aluminum tanks leaking. He had replacement tanks fabricated & when installing them, a year later had the same leaks. I did tell him that I would not reconnect the bonding wire to the tanks. He did, needed new tanks, a year later. This time he didn't connect the ugly green wire. He now uses an alligator clip on the bonding wire to the tank only when he is fueling. By the way, the tanks all had holes in the mid bottom areas. Where was your leak?

He is in a closed bayou with a lot of liv-a-boards all hooked up to electrical systems, hence the stray current. Some will disagree with this but that's OK, as I no longer have issues with electrolysis & aluminum.

CR

CR

my filters have also looked good. The stuff that settles doesn't normally get pulled up as the pickup tube is a good inch off the bottom of the tank. But when u encounter weather conditions that stir it up, it's a different scenario. A dockmate of mine went to San Diego last August. He went through his whole fuel system excepting the tank. And... he got in trouble with a weather system and started sucking the crap up and you know the rest. As for jerry cans, that could sometimes work, however, when you're in the islands up north, that hardly is an option. And, it's a lot of work with a 55 gal tank....My fuel tank isn't currently leaking. I'm replacing it so I know I won't have a mess to contend with if it did. And, the boat is used..That's why we have it. As for the green wire, fuel being loaded into the tank and also sloshing around will pickup a static charge that can be pretty hefty. I think I'd like to dissipate that...

Mark, I understand your point. I wasn't trying to be contrarian, and understand the issues, just pointing out that I've been out in some really knarly stuff (http://c34.org/bbs/index.php/topic,6783.msg46861.html#msg46861) and have had no problems.

FWIW, bonding and grounding are two very separate issues. Bonding should never have current running through the system, although they both get grounded to the engine. The West Advisors online have a very good writeup in the electrical section. http://www.westmarine.com/webapp/wc...01&page=Marine-Grounding-Systems#.UnU2WxCQORM

Ron's fuel source ideas are very proper. We are fortunate: There used to be two fuel docks on our Estuary, one closed. The remaining one gets heavy turnover, since the coast guard uses the Estuary and fuels up their diesel fired 50+ foot boats there. Takes a while, so don't get caught waiting behind one (ask me how I know... ).

).

FWIW, bonding and grounding are two very separate issues. Bonding should never have current running through the system, although they both get grounded to the engine. The West Advisors online have a very good writeup in the electrical section. http://www.westmarine.com/webapp/wc...01&page=Marine-Grounding-Systems#.UnU2WxCQORM

Ron's fuel source ideas are very proper. We are fortunate: There used to be two fuel docks on our Estuary, one closed. The remaining one gets heavy turnover, since the coast guard uses the Estuary and fuels up their diesel fired 50+ foot boats there. Takes a while, so don't get caught waiting behind one (ask me how I know...

I agree with you, Stu. Dirty fuel tanks are a problem, but I don't think you should assume you have that problem unless evidence points to it. Access plates are a real plus and fuel polishers are great but not everybody needs them.Mark, I understand your point. I wasn't trying to be contrarian, and understand the issues, just pointing out that I've been out in some really knarly stuff (http://c34.org/bbs/index.php/topic,6783.msg46861.html#msg46861) and have had no problems.

).

I have an 80 gallon tank built into the glass hull of my boat, and I'm sure no one has seen the inside in at least 30 years, perhaps not since 1961 when the boat was built.

Huge steel plates are the covers held down with a few hundred bolts.

I change my primary and secondary filters every other season which amounts to about 200 hours. If I had any fuel starvation problems, I'd do it annually. I also check the water separator bowl at least annually.

Last season I pulled the 1" fuel gauge and ran a hose down to the lowest crevice(that was easy to find "feel" as the sender is over the lowest spot. After several tries, I finally pulled up an eyedropper of sediment and a plug of water the size of a small marble. Crystal clear fuel otherwise. I use a cetane booster for each 40 gallons and add nothing else. Tanks are topped off each fall for winter layup.

This is not to say I wouldn't love an access plate but it's just not feasible. Some day, the huge tops will need to be pulled, but it won't likely be me.

Over 15 seasons, I've shaken this boat up about as much as is possible short of pitchpoling. And I think fuel polishers are great if your tank needs them but my filters are working as the fuel polisher they were designed for.

I think the basic fuel filtering system and the the filter feedback is the first indicator of the health of your fuel tank.

After 32 years my tanks are truly filthy. I change my filters regularly and have few problems.

I could only access one section of three through any access port as things are; it would require cutting two more hatches in the salon floor to have three. It isn't going to happen unless I have to install a new tank.

Taking on fuel in 3rd world countries is a crap shoot anyway; it's a good thing I have a sailboat!

I could only access one section of three through any access port as things are; it would require cutting two more hatches in the salon floor to have three. It isn't going to happen unless I have to install a new tank.

Taking on fuel in 3rd world countries is a crap shoot anyway; it's a good thing I have a sailboat!

You boys with the big toys have baffles that would require multiple inspection ports. Allan's post describing the installation and cleaning of the H31 plastic tank shows no baffles in the tank. I would install a port were they not so costly. I have inquired of those who sell plastic inspection ports and they cannot say whether they are diesel fuel resistant or robust enough for this application. I'm not about to experiment. I have queried a manufacturer of the ports and a tank fabricator but no reply yet.

Unless the West Coast is vastly different in its fuel filling laws the fuel you get from a fuel pump in the US is already filtered down to about 30 micron but many stations filter to 10 micron. The filters mandated here in Maine are a non-bypass design meaning instead of bypassing when they clog they just reduce flow until the station owner changes them. The marina I fill at uses 10 micron Cim-Tek HSV filters which also shut down the minute water is detected.I emptied the fuel tank today and after three years, there was a lot of crap settled on the bottom of the tank. Nothing growing on the sides etc. The tank itself was really clean. I treated all fuel with Stanadyne. I expected some "stuff" but what I found was really surprising. All fuel that I have purchased has been from major fuel suppliers etc. I'm going to start filtering fuel that I take onboard.

I used a Baja and Parker pre-fiter for a few weeks before my marina owner pointed out the level of filtration required by Maine law was far better than what I was doing. I just had to laugh at myself.... The Baja or Parker are only 80+ micron screens and it is no wonder I never caught anything...

Even when pre-filtered stuff can grow in your tanks especially if your deck fill or vent leaks water in there. It may not be coming in at the visible level of filtration but once in there can grow..This also tells me that I need to open the tank up every few years and clean it out. My new tank will definitely have an access plate upon fabrication. There have been a few threads on fuel tanks and people seem to be reluctant to opening a tank putting an access plate in the tank. DO IT!!!! Before you are forced to do it.......

I installed an on-board polishing system when I did the tank four years ago. I was just in there in August and the tank looks like brand new, just bare shiny aluminum and bright red, very, very clear fuel..

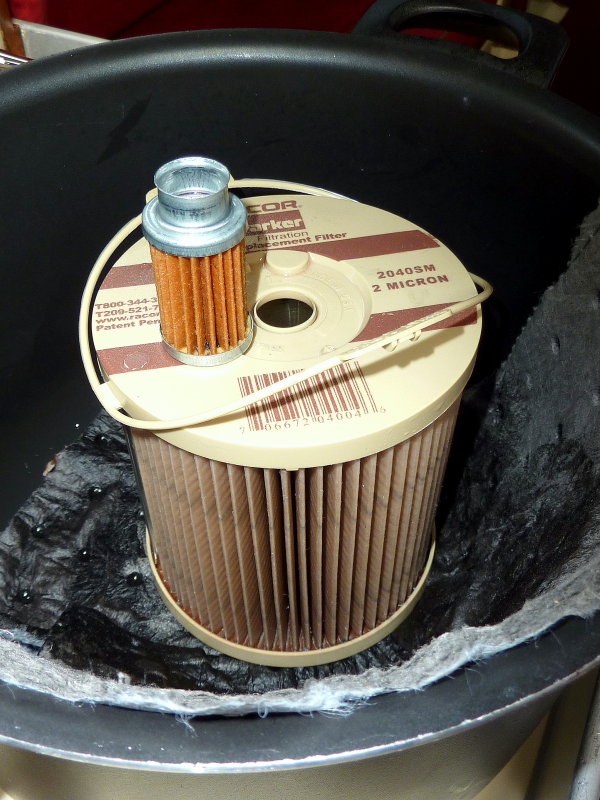

The entire system cost less than $350.00 but can be done for a lot less. I used a Racor 900 (overkill but I like it) and a Walbro pump. I also installed dedicated supply and return tapping to the tank when I built it..

Our polishing system turns the fuel tank over approx twice per hour and runs when ever the engine does, or when ever we need it to. Since installing the polishing system NO ADDITIVES have been added into the tank, none. The Valvetect fuel I buy is supposed to be treated and they advise not adding anything else.. I had used additives in the old tank and they did less than nothing at keeping the tank clean....

Our boat had used Soltron well before it was marketed in the US as Startron, and it had been in use religiously for the last 15+ years, yet this is what the interior looked like. It should also be noted that this was after TWO treatments Startron Enzyme Formula Diesel Fuel Tank Cleaner. Fuel tank "cleaner"? Really? Not in my experience... Oh and this tank had also been "professionally" polished by a dock side fuel polishing outfit. Polished? Really?

I now use only Valvetect fuel and so far in four years with on-board polishing it is working far better than could every be expected.

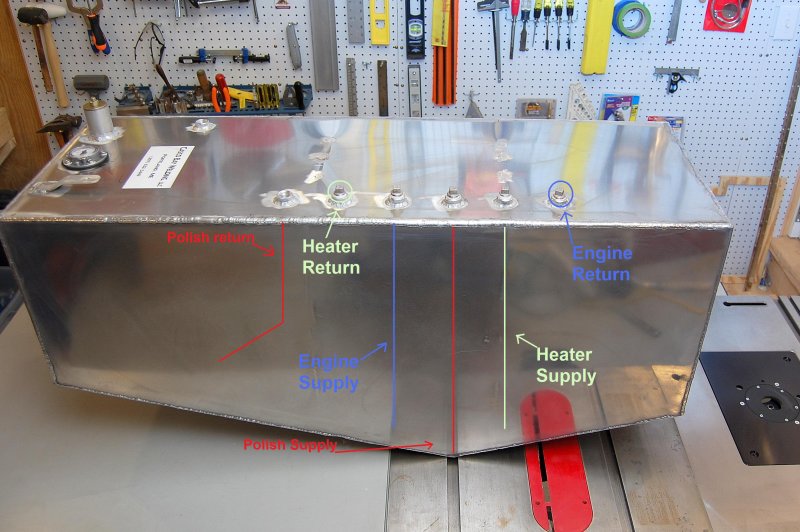

This is our tanks piping layout.

One other thing that may be different, for us, is that I do not believe in filling my fuel tank in the winter. It is drained, not filled....

The first season we ran the fuel polishing system for roughly 190 hours and the engine for 111 hours. The second season the polishing system ran for 300 hours and the engine for 122 hours (we have engine driven refrigeration so the engine runs more than most). The third season we ran the polishing for 277 hours and the engine for 127 hours. These are the 2 mic polishing filter and secondary filter for the Westerbeke after 360 total hours of engine running time over a three year period. I inspected them each season then re-installed them just to see how long it would take for them to get "dirty". The primary Racor looks as new..

I also use a drag needle vacuum gauge on the polishing system.. This picture shows the original Carter fuel pump that was not designed for continuous duty. I later replaced it with a Walbro specifically engineered for continuous use.

Our system has exceeded my expectations and I know that in the future I will never own another diesel powered boat without a dedicated on-board polishing system...

One thing you may look at in addition to the crud that Maine Sail shows in his old tank and which I had in my old tank, is the formation of a slimy kind of growth in the fuel. Periodically take a sample from the tap on the bottom of the filter into a Ziploc bag that is clear so you can see through it and visually see what the fuel looks like. It is easy to see if it is perfectly clear or if it is contaminated with anything. You can also use a mason jar or I suppose a test tube. A Ziploc is easy because it can fit in any space.

Maine, thanks for the post. I should (will) have the tank fittings installed when the tank is built. Is there a reason why you put everything on one side of the tank? Does it make sense to put the polishing return on one side and supply on the other side (also deep end)? I have access to whole top side. It's a wide (not very deep) tank. What p/n Walbro did u use?

They are not on one side. The polisher pick up is at the dead bottom vee in the tank and picks up 1/8" off the dead absolute bottom. That tnak runs port to starborad and has a slight, 1 to 2 degree angle forward.Maine, thanks for the post. I should (will) have the tank fittings installed when the tank is built. Is there a reason why you put everything on one side of the tank? Does it make sense to put the polishing return on one side and supply on the other side (also deep end)? I have access to whole top side. It's a wide (not very deep) tank. What p/n Walbro did u use?

The polish return is via a dip tube that goes nearly to the bottom and has a hook in it to create a swirl motion as it returns. The return dip tube also prevents foaming....

The pick ups and returns all return different chambers.. I was going to do a heater re-circ loop but decided to only use the pick up so I technically have one extra tapping left over...

The ziploc bag is a good idea. There's not much space below my Racor to test for water.One thing you may look at in addition to the crud that Maine Sail shows in his old tank and which I had in my old tank, is the formation of a slimy kind of growth in the fuel. Periodically take a sample from the tap on the bottom of the filter into a Ziploc bag that is clear so you can see through it and visually see what the fuel looks like. It is easy to see if it is perfectly clear or if it is contaminated with anything. You can also use a mason jar or I suppose a test tube. A Ziploc is easy because it can fit in any space.

For taking samples from the bottom of the tank, I filled several plastic coke bottles this spring until I was satisfied. They proved to be a good visual held to the light showing any sediment or water.

This test in conjunction with fuel filters doing their job without problems tells me, all's well in my tanks.

I had the occasion once to clog my filters after crossing the bay for 1 hour of very rough seas. I want to change my old racor filter that has no clear bowl but my avail space is really limited. Is there a height above the fuel tank that the new Racor 500 can be installed? I have a 3gm30 Yanmar and I'm told there's a fuel pump but it's week so I wonder of its ability to pull fuel uphill. Thanks.

Cox,

The fuel pump works on suction, my secondary fuel filter is higher than my pump.

Never a problem.

I installed a low point ball valve downstream of my tank. When having filter problems, I first turn this valve closed. This stops the fuel from equalizing & will leave less air in the lines. I also keep a quart of spare(clean) diesel fuel in a container. I remove the filters & when replacing with new, I fill these NEW filters with this diesel as close to the top as I can. I install the filters & with the valve in the closed position, have little air with which to bleed. When ready to start-er-up, first open this valve up.

I can thus take 2 or 3 attempts at starting without bleeding the system. Once running, be patient & slowly increase the throttle in neutral until you hear no more coughing. This works with my universal 3M20, your engine may require bleeding, but hey, try this method & see if it works.

Remember to NEVER engage the starter button for more than 10 to 15 seconds. If it hasn't started by then, stop & repeat. You don't want to suck water up into the engine from your exhaust system.

CR

The fuel pump works on suction, my secondary fuel filter is higher than my pump.

Never a problem.

I installed a low point ball valve downstream of my tank. When having filter problems, I first turn this valve closed. This stops the fuel from equalizing & will leave less air in the lines. I also keep a quart of spare(clean) diesel fuel in a container. I remove the filters & when replacing with new, I fill these NEW filters with this diesel as close to the top as I can. I install the filters & with the valve in the closed position, have little air with which to bleed. When ready to start-er-up, first open this valve up.

I can thus take 2 or 3 attempts at starting without bleeding the system. Once running, be patient & slowly increase the throttle in neutral until you hear no more coughing. This works with my universal 3M20, your engine may require bleeding, but hey, try this method & see if it works.

Remember to NEVER engage the starter button for more than 10 to 15 seconds. If it hasn't started by then, stop & repeat. You don't want to suck water up into the engine from your exhaust system.

CR