This is by far the worst job I have ever done on my boat. We had to cut out and replace all of our chainplate knees except for the aft lowers due to water intrusion and rot. Here you can see the starboard cap shroud knee and how wet the core was. You could push it with your finger and water would come out.

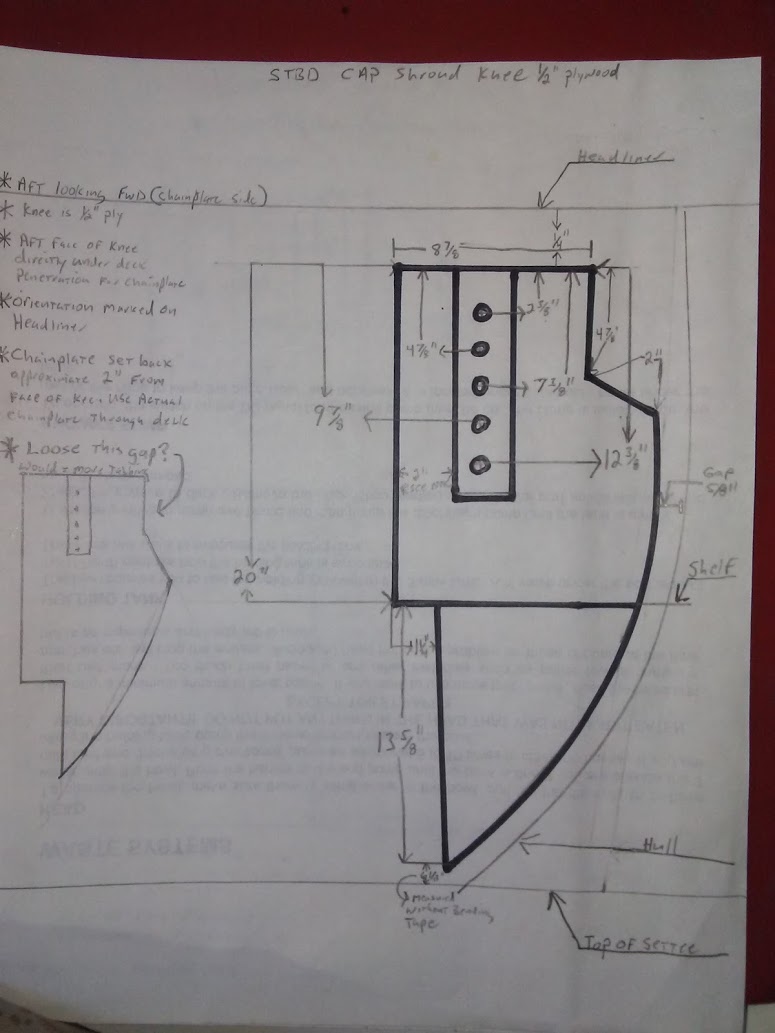

Careful measurements were taken and sketches made of all the knees placement before they were cut out. Their orientation was also marked with pencil on the headliner so the new knee could be placed in the exact same position.

After the chainplates were removed I used a bimetal saw blade on an oscillating multi tool to cut through the tabbing and remove the bad knees.

Then the hard part... Days of miserable grinding inside the boat to remove the old tabbing. I have found that 36 grit zirconia flap discs (changed often) on an angle grinder are about the best thing for grinding through fiberglass. I also put up plastic sheeting in an attempt to contain the dust but this was a complete waste of time because the dust found its way behind it anyway. It looked like a blizzard hit inside the boat.

I measured how far out from the hull each knee protruded and then ground away the same distance on each side.

After seemingly endless vacuuming and cleaning, new knees were made using 1/2" baltic birch marine ply for the cap shrouds and 3/4" teak faced marine ply (to mach the bulkheads) for the forward lowers knees. All were encapsulated in epoxy.

A spacer fillet of xps foam was made to space the knees from the hull to avoid any "hard spots" and glued in place.

Then the new knees were put in place and temporarily held by wooden shims.

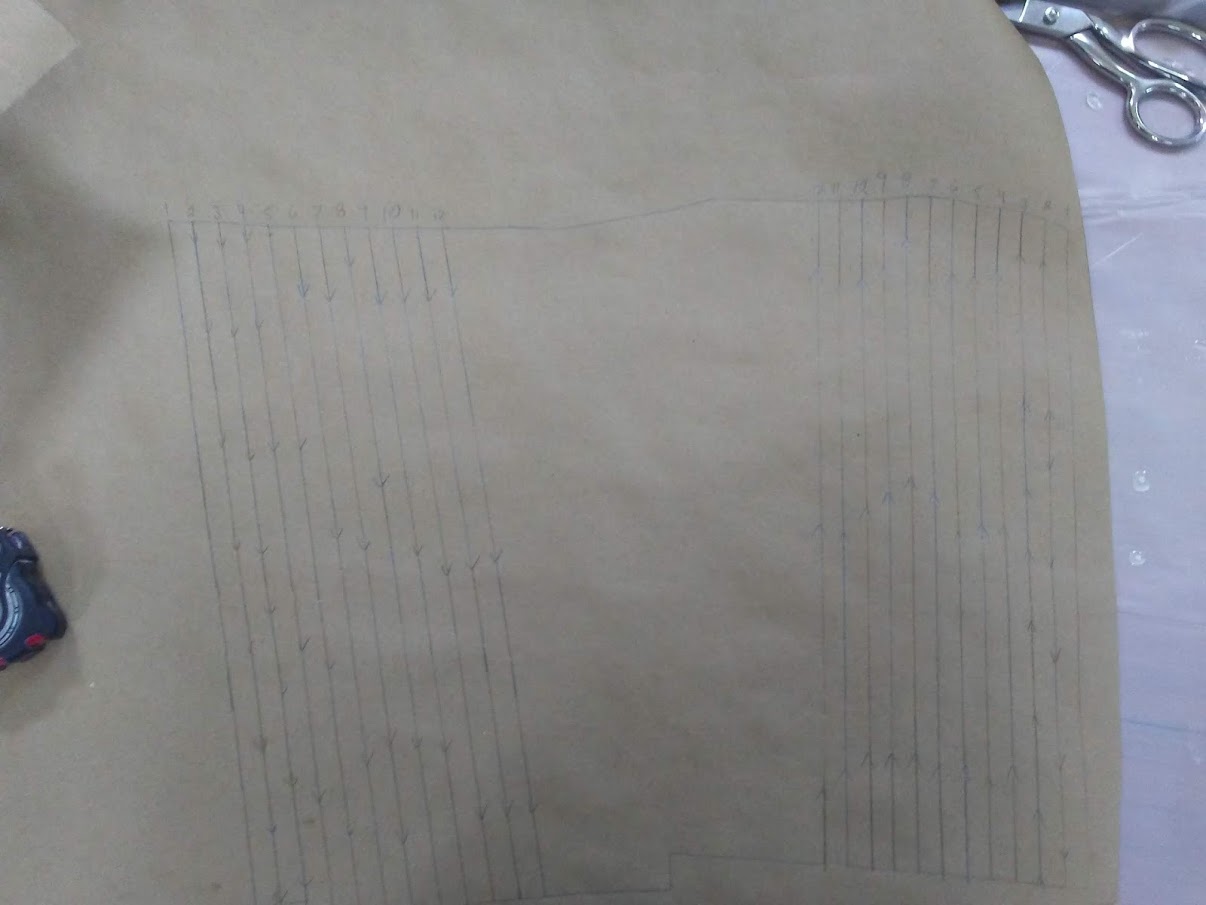

Craft paper was then used to make a template for cutting what would be the new fiberglass tabbing. The tabbing was to be made of 12 layers of 1708 biaxial mat each 1 inch smaller (width wise) than the one laid below it. This is to spread the load from the rigging over a greater section of the hull to which it is bonded.

The template was then used to cut the fiberglass cloth for the new tabbing. The orientation of the cloth was alternated to create the strongest layup possible.

It seems I have reached the attachment limit so this will be continued in the comments....

Careful measurements were taken and sketches made of all the knees placement before they were cut out. Their orientation was also marked with pencil on the headliner so the new knee could be placed in the exact same position.

After the chainplates were removed I used a bimetal saw blade on an oscillating multi tool to cut through the tabbing and remove the bad knees.

Then the hard part... Days of miserable grinding inside the boat to remove the old tabbing. I have found that 36 grit zirconia flap discs (changed often) on an angle grinder are about the best thing for grinding through fiberglass. I also put up plastic sheeting in an attempt to contain the dust but this was a complete waste of time because the dust found its way behind it anyway. It looked like a blizzard hit inside the boat.

I measured how far out from the hull each knee protruded and then ground away the same distance on each side.

After seemingly endless vacuuming and cleaning, new knees were made using 1/2" baltic birch marine ply for the cap shrouds and 3/4" teak faced marine ply (to mach the bulkheads) for the forward lowers knees. All were encapsulated in epoxy.

A spacer fillet of xps foam was made to space the knees from the hull to avoid any "hard spots" and glued in place.

Then the new knees were put in place and temporarily held by wooden shims.

Craft paper was then used to make a template for cutting what would be the new fiberglass tabbing. The tabbing was to be made of 12 layers of 1708 biaxial mat each 1 inch smaller (width wise) than the one laid below it. This is to spread the load from the rigging over a greater section of the hull to which it is bonded.

The template was then used to cut the fiberglass cloth for the new tabbing. The orientation of the cloth was alternated to create the strongest layup possible.

It seems I have reached the attachment limit so this will be continued in the comments....