Maine Sail uses butyl tape instead of caulking for sealing deck penetrations. I have never worked with this and I thought I'd try it. I see online all sorts of different butyl tapes - the main difference apparently is the shape of the tape. Maine Sail - what sort do you recommend?

butyl tape

- Thread starter John

- Start date

- Status

- Not open for further replies.

I get mine at a local RV store or from McMaster-Carr but the last time I looked they only had black. I do not use it to bed everything though. It has it's place, as do other sealants, but it really is great stuff if you prep right.. Do not use it below the waterline!!I bought enough to last "forever" for $20 + shipping. I have Mac 26D HW to rebed - but the big part is for restoration on another board - and for my son in law... $5 should last for most anyone from MMC.

--jr

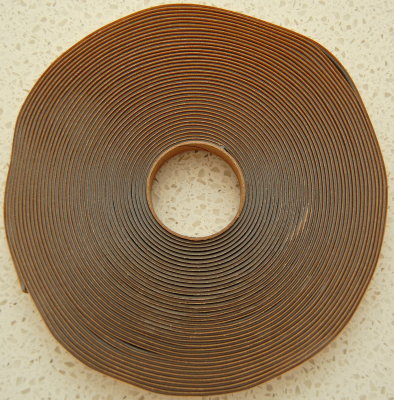

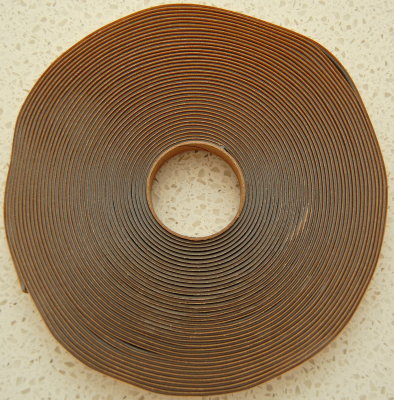

The stuff I mostly use is about 1/2" wide by 1/8" thick flat butyl tape in gray. I don't advise using black!!!

RV Wholesalers - Off White Butyl Tape

Not sure that is butyl tape - looks just like this stuff which, although not intended for deck hardware, is excellent on all electrical connections and I've used it for decades on outdoor connections for my ham radio cables.

http://www.coaxseal.com/

http://www.coaxseal.com/

No..

No, it is not at all like Coax seal have used that stuff and other similar brands.. It is butyl rubber..Not sure that is butyl tape - looks just like this stuff which, although not intended for deck hardware, is excellent on all electrical connections and I've used it for decades on outdoor connections for my ham radio cables.

http://www.coaxseal.com/

Thanks Tim I'll save that part number!! If you type "butyl tape" into their search engine all you get is black??The stuff I got at McMaster is gray. It is not listed under their butyl tape section. They call it butyl rope.

That is true. I actually forget how I found it. I could not find it again and thought maybe they discontinued it but I looked up my order and was able to find it by searching by part number. It is listed under glazing compounds(stay-soft glazing rope). Even if you search by "butyl" it does not come up.

Man, who'd have ever thought that I'd get 9 responses to a question on butyl tape. Thanks, guys! I just ordered a roll of that tape that Tim mentioned. Next after pulling the mast, rerigging the standing rigging, replacing the bulkhead -- resealing the deck penetrations with the method that Main Sail recommends. Then after that comes replacing the packing. After that -- off to Mexico (I wish).

Tim...The stuff I got at McMaster is gray. It is not listed under their butyl tape section. They call it butyl rope.

I couldn't open your attachement so would appreciate it if you'd post McMaster's part number.

Thanks,

Paul

Advantage?

What do you see the advantage of the butyl tape over traditional "caulking" such as 4200, Silicone or other products?

What do you see the advantage of the butyl tape over traditional "caulking" such as 4200, Silicone or other products?

I get mine at a local RV store or from McMaster-Carr but the last time I looked they only had black. I do not use it to bed everything though. It has it's place, as do other sealants, but it really is great stuff if you prep right.. Do not use it below the waterline!!

The stuff I mostly use is about 1/2" wide by 1/8" thick flat butyl tape in gray. I don't advise using black!!!

RV Wholesalers - Off White Butyl Tape

Here you go Paul. 1049A31Tim...

I couldn't open your attachement so would appreciate it if you'd post McMaster's part number.

Thanks,

Paul

Lots but mostly flexibility and it's ability to remain flexible for 30+ years or more!!! remember Butyl should never be used below water but has great utility in bedding mechanically fastened deck hardware.What do you see the advantage of the butyl tape over traditional "caulking" such as 4200, Silicone or other products?

Mechanically fastened hardware is MECHANICALLY FASTENED and usually or should have substantial backing plates to ensure it does not rip free from the deck. You absolutely positively do not need to glue something to your deck that is already through bolted, torqued and backed up with backing plates. All the sealant has to do is be flexible and adhere to each surface enough to not part during any flexing or movement. Butyl is a lot more flexible than any cured polyurethane or polysulfide. In fact polyurethanes continue to harden and become more brittle with time and lose elongation charecteristics something butyl does not suffer from for many, many years.

Our 30 year old boat is bedded, and was bedded from the factory, entirely with butyl rubber. Buytl has about a 10 -20 PSI adhesion but is MUCH, MUCH, MUCH more flexible than any polysulfide or polyurethane. Over 80% of the fittings on my deck, including the deck to hull joint, are still bedded with the original butyl from 30 years ago!! It's still flexible and still NOT leaking.

You do not need to glue mechanically fastened hardware to the deck but it does need to be flexible and seal out moisture butyl tape does this as do the lower adhesion polysulfides like LifeCaulk & 3M 101.

You're looking at an elongation of well over 3000%. This butyl bedded cleat was removed at the 29 year mark, still BONE DRY and very, very flexible!

The Core Was Still Bone Dry:

Tim...

I couldn't open your attachement so would appreciate it if you'd post McMaster's part number.

Thanks,

Paul

Paul,

The gray round stuff from Mcmaster will work but it is harder to knead and make flat to install under a deck fitting than the flat ribbon style butyl tape. I usually use 1/8" thick by 1/2" wide FLAT butyl. You can cut strips and adhere them to underside of the deck fitting then knead some butyl cones around the bolt shanks and install it. I posted a link above to an RV dealer who has white flat butyl tape and it's very inexpensive. I think you'll find the flat is much easier to work with than the round..

Don't forget to countersink the holes slightly to create a nice thick o-ring effect..

Buytl tape is not a panacea but a good alternative for certain uses. I do not use it to bed dissimilar metals, nor underwater, dead lights or hatch Lexan. It can be used for many things above deck where you would use a product like 4200, Life Caulk or 3M 101.. Each installation has a sealant that will work best. As much as I hate Sillycone (silicone) I would not install a Beckson port or a replacement lens for a hatch with anything but Dow 795 silicone...

Here's one last photo (the same one from a post above). It shows a cutaway view of a section of deck core that has been potted with epoxy and then countersunk to create an o-ring effect.

In a mechanically fastened joint, genny track, stanchion, traveler, deck cleat etc. you will NEVER, EVER see movement like this and if you do you have way more trouble than a failed sealant!! Remember this is a Butyl tape bond strength of about 10-20 PSI, not 800 PSI, not even 100 PSI, just 10-20, which is nowhere near the 502 PSI of 5200 bonding to gelcoat, or 362 PSI of 5200 bonding to stainless steel.

- Status

- Not open for further replies.