Best thread sealant for exhaust coupler

- Thread starter robertsapp

- Start date

- Status

- Not open for further replies.

Beat thread sealant for exhaust coupler

I'd like opinions on the best thread sealant to use on the exhaust coupler on a Yanmar 3GM30F. This is the small coupler that fits between the exhaust elbow and the mixing elbow. One end is threaded normally, the other is reverse threaded, and it connects the exhaust elbow and mixing elbow together. I assembled mine with a heavy coat of antisieze compound and tightened it sufficiently (I thought) but I suspect I might be getting a tiny bit of exhaust leaking, so I'm wondering if there's something else I should be using rather than antisieze paste on this joint. Thanks!

I'd like opinions on the best thread sealant to use on the exhaust coupler on a Yanmar 3GM30F. This is the small coupler that fits between the exhaust elbow and the mixing elbow. One end is threaded normally, the other is reverse threaded, and it connects the exhaust elbow and mixing elbow together. I assembled mine with a heavy coat of antisieze compound and tightened it sufficiently (I thought) but I suspect I might be getting a tiny bit of exhaust leaking, so I'm wondering if there's something else I should be using rather than antisieze paste on this joint. Thanks!

I use standard 'heavy duty muffler cement'.

example: http://www.jegs.com/i/Dynomax/289/35958/10002/-1?CT=999 price varies greatly depending on supplier/source.

example: http://www.jegs.com/i/Dynomax/289/35958/10002/-1?CT=999 price varies greatly depending on supplier/source.

You don't specifically say what "threads" you're talking about?I' d

For NPT pipe threaded adapters I've been using Hercules Real-Tuff teflon thread sealant for over 20 years in this application. Seals well, does not dry out and parts will come apart easily in the future. Home Depot stocks it. If replacing an exhaust elbow or such I would strongly suggest schedule 80 pipe vs. schedule 40 for any fittings or nipples you may need..

Re: Beat thread sealant for exhaust coupler

I was once told by a diesel mechanic, working for a Yanmar dealer, that Silicone Rubber was the better sealant to use to both seal exhaust leaks and alow it to come apart when needed. But, I'm sure many others here have better insight.

I was once told by a diesel mechanic, working for a Yanmar dealer, that Silicone Rubber was the better sealant to use to both seal exhaust leaks and alow it to come apart when needed. But, I'm sure many others here have better insight.

Maine - be very careful with such recommendations for the use of 'teflon' in any hi temp exhaust application.

'Teflon - PTFE, ECTFE, et al 'sublimes' into a gas at over ~650°F, exhaust gasses and its containment piping can well exceed that temp. Better to use a "PFA" (a PTFE 'analogue') filled sealant (softens at 752°F) than PTFE filled.

Better not to use (nor recommend) 'any' compound that will 'sublime' at high temp. -- a 'safety issue'.

Graphite filled sealants were especially formulated for 'hi temp' pipework. ;-)

'Teflon - PTFE, ECTFE, et al 'sublimes' into a gas at over ~650°F, exhaust gasses and its containment piping can well exceed that temp. Better to use a "PFA" (a PTFE 'analogue') filled sealant (softens at 752°F) than PTFE filled.

Better not to use (nor recommend) 'any' compound that will 'sublime' at high temp. -- a 'safety issue'.

Graphite filled sealants were especially formulated for 'hi temp' pipework. ;-)

Re: Beat thread sealant for exhaust coupler

That joint on that engine normally operates at around 350-450F (under load) on the lower part.. That is right at the max temp for the "high heat" silicone sealants..I don't think I would use silicone on that joint unless you can find some rated for about 500F.. Since that is a pipe threaded fitting, you should be able to tighten it enough that the anti-seize and the pipe threads will seal. ?? The nipple is threaded opposite hand so that you can hold the elbow in position and turn the hex on the nipple and tighten (or loosen) both sets of threads at the same time. You can set the tightness by starting one set of threads before the other.. For instance.. if you suspect the lower end is leaking, start the nipple in the lower end about a half or three fourth of a turn before putting on the elbow and turning the hex on the nipple to make up both joints.. Good luck..

EDIT: EDIT: Sounds like MainSail has a good high temp product .. listed on the other post..

That joint on that engine normally operates at around 350-450F (under load) on the lower part.. That is right at the max temp for the "high heat" silicone sealants..I don't think I would use silicone on that joint unless you can find some rated for about 500F.. Since that is a pipe threaded fitting, you should be able to tighten it enough that the anti-seize and the pipe threads will seal. ?? The nipple is threaded opposite hand so that you can hold the elbow in position and turn the hex on the nipple and tighten (or loosen) both sets of threads at the same time. You can set the tightness by starting one set of threads before the other.. For instance.. if you suspect the lower end is leaking, start the nipple in the lower end about a half or three fourth of a turn before putting on the elbow and turning the hex on the nipple to make up both joints.. Good luck..

EDIT: EDIT: Sounds like MainSail has a good high temp product .. listed on the other post..

Last edited:

But isn't this a wet exhaust that is under discussion?Maine - be very careful with such recommendations for the use of 'teflon' in any hi temp exhaust application.

'Teflon - PTFE, ECTFE, et al 'sublimes' into a gas at over ~650°F, exhaust gasses and its containment piping can well exceed that temp. Better to use a "PFA" (a PTFE 'analogue') filled sealant (softens at 752°F) than PTFE filled.

Better not to use (nor recommend) 'any' compound that will 'sublime' at high temp. -- a 'safety issue'.

Graphite filled sealants were especially formulated for 'hi temp' pipework. ;-)

Rich,Maine - be very careful with such recommendations for the use of 'teflon' in any hi temp exhaust application.

'Teflon - PTFE, ECTFE, et al 'sublimes' into a gas at over ~650°F, exhaust gasses and its containment piping can well exceed that temp. Better to use a "PFA" (a PTFE 'analogue') filled sealant (softens at 752°F) than PTFE filled.

Better not to use (nor recommend) 'any' compound that will 'sublime' at high temp. -- a 'safety issue'.

Graphite filled sealants were especially formulated for 'hi temp' pipework. ;-)

I used to rep for Hercules so know the products capabilities quite well.. That sealant is rated & tested to +550F at 12,000 hydraulic PSI and 2600PSI gas pressure. Go above +550F and you may have a leak at below 12,000PSI hydraulic or 2600PSI gas pressure.. At less than 3 PSI in an exhaust system, never, ever seen a leak. Real-tuff can withstand temps in excess of its rating quite well and still not allow a leak. I had many guys in facilities show me how well it did when pushed well beyond its temp "rating"..

I have personally seen it on a 800F situation come apart as easily as it went together. Even though it technically should have been "melted" the fittings never leaked and still came apart easily. Over the years as a rep I got to see it do some amazing things, in industry, where it is a highly favored product.

If your diesel exhaust is getting hot enough to cause a thread leak with Real-Tuff there is likely another problem that needs addressing. These exhaust manifolds rarely exceed 400F and I measure a lot of them. When I see 400+ it is usually a red flag for a plugging exhaust elbow. With most of these engine the exhaust manifold is "water jacketed" which helps to cool the exhaust before it even hits threaded pipe, this is why the paint survives.

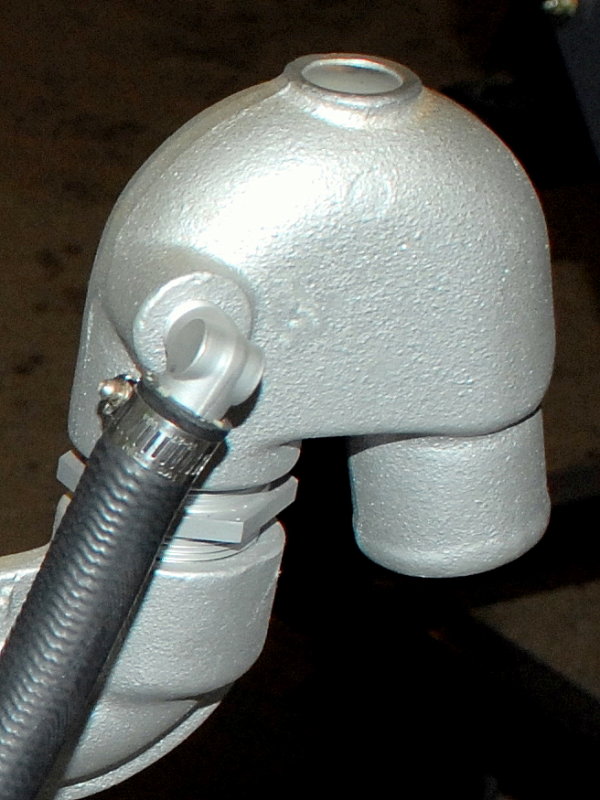

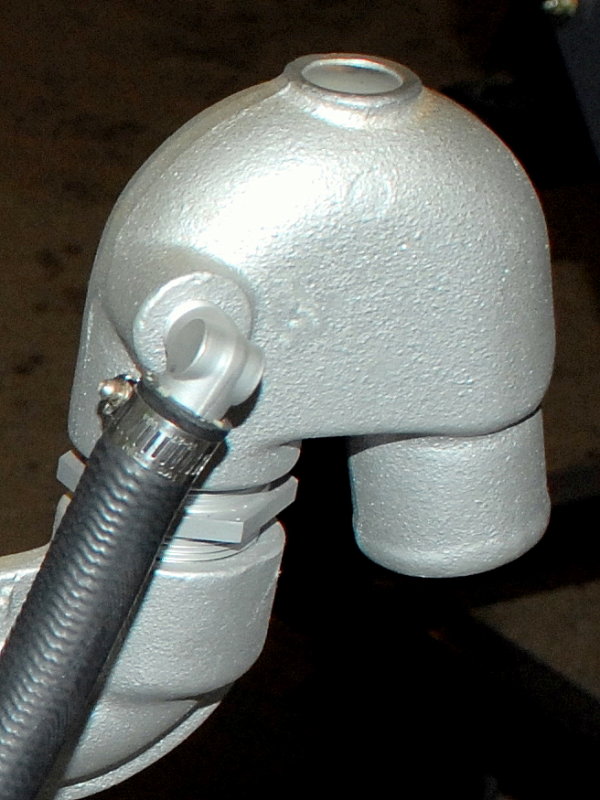

This is our engine at the solid aluminum part of the manifold. I've seen it as high as about 240F....

I have also been using Real-Tuff in this no PSI application for over 20 years and in that time removed many exhaust pieces put together with it. Comes apart like it went together and never once had a single threaded joint leak.

Many of these exhaust fittings & manifolds are also factory painted. None of these factory paints will survive much above 400F. Even the highest temp ceramic type engine paints are rated to only 550F..

Maine - I understand that for 'normal' operating temps this will work ... but consider those 'transients' when the 'cooling' of an exhaust system is restricted, etc. and those temps. go 'exponential'.

Graphite (and white-lead or 'refactory') bearing sealants will withstand such 'swings' and stay 'put', the teflonics simply 'off gas'.

Graphite (and white-lead or 'refactory') bearing sealants will withstand such 'swings' and stay 'put', the teflonics simply 'off gas'.

Rich,Maine - I understand that for 'normal' operating temps this will work ... but consider those 'transients' when the 'cooling' of an exhaust system is restricted, etc. and those temps. go 'exponential'.

Graphite (and white-lead or 'refactory') bearing sealants will withstand such 'swings' and stay 'put', the teflonics simply 'off gas'.

Those certainly work but it is not really all that necessary. One of the largest Westebeke distributors in the country uses Rector Seal on these fittings, have for years. They claim it is what the factory uses/used. The sealant this distributor uses is rated at 400F. A thread sealant is lubricating the threads to get them together and filling in potential leak gaps. In a perfect world there would not be any leaks in a tapered NPT to NPT thread if properly mated.

At less than 3 PSI I have never once seen a thread leak even when the factory or Westerbeke distributor used Rector Seal. I have also never experienced one and have done more exhaust work than I care to.. I have a Rector Seal mated exhaust elbow on my bench right now that came apart just fine and had no signs of any thread leakage despite the elbow being "plugged"..

This fitting, a badly plugged and failed exhaust elbow, was done with Rectorseal, which is a 400F rating. No evidence of any threaded leaks and the female threads were still perfectly clean and rust free when the elbow disintegrated..

Mack Booring, the Yanmar distributor, does not even use or suggest a thread sealant on NPT/tapered pipe fittings. They suggest any "lubricant" used when putting them together can work quite well. This goes aginst conventional "piping wisdom" but apparently works..

Yanmar ships engines like this one with no sealant on the tapered pipe threads.

What ever pipe dope you use is better than the above photo even if it were to "off gas" in the rare situation that the temp exceeded 630F..

Interestingly enough Real-Tuff is temp rated higher than any of the Permatex "High Temp" thread sealants they sell. If you want a higher temp rating any of the graphite based Anti-Seize products can exceed 1000F and can be found at any auto parts store. If there are thread defects they won't seal as well but can work in a properly tightened, clean NPT to NPT fitting. At 3 PSI or less the risk of a well lubricated, with dope or not, NPT to NPT fitting leaking is going to be quite rare..

The Best You Are ...................................

................................. going to find is any pipe sealant which is lead based such as Masters Metallic Compound. You'll want to use a pipe sealant and not a parting compound for this job as the sealant actually has body to it and will seal the threads as opposed to an anti-sieze compound which only ensures the joint will not gall under the high temperature but does not have the body to seal.

The other nice thing here is that you don't have to reef the bejabbers out of the two joints, just tight enough to ensure they do not unscrew due to the engine vibration. I have used this for half a dozen removals for cleaning and never had a problem with leakage or disassembly.

With regards to max. temp. you'll notice that Masters Metallic temp. limit is 550 deg. F. I know that I've taken an infrared shot of the coupling on my 2GM20F under load and found the temp. to be around 325 deg. F. while the mixing elbow runs cold due to the volume of cooling water it sees. The elbow seems to hold the temp. of the coupling quite low.

On the other hand, I have seen pipe fittings disassembled on a utility diesel dry exhaust which is probably closer to 1,000 deg. F and seen no problems where Masters Metallic was used. I was told that the catch was NOT to reef the hell out of the joints as there is little pressure and just tight enough to keep everything from shaking apart.

................................. going to find is any pipe sealant which is lead based such as Masters Metallic Compound. You'll want to use a pipe sealant and not a parting compound for this job as the sealant actually has body to it and will seal the threads as opposed to an anti-sieze compound which only ensures the joint will not gall under the high temperature but does not have the body to seal.

The other nice thing here is that you don't have to reef the bejabbers out of the two joints, just tight enough to ensure they do not unscrew due to the engine vibration. I have used this for half a dozen removals for cleaning and never had a problem with leakage or disassembly.

With regards to max. temp. you'll notice that Masters Metallic temp. limit is 550 deg. F. I know that I've taken an infrared shot of the coupling on my 2GM20F under load and found the temp. to be around 325 deg. F. while the mixing elbow runs cold due to the volume of cooling water it sees. The elbow seems to hold the temp. of the coupling quite low.

On the other hand, I have seen pipe fittings disassembled on a utility diesel dry exhaust which is probably closer to 1,000 deg. F and seen no problems where Masters Metallic was used. I was told that the catch was NOT to reef the hell out of the joints as there is little pressure and just tight enough to keep everything from shaking apart.

Attachments

-

72.7 KB Views: 719

Re: Beat thread sealant for exhaust coupler

Unless I missed something the exhaust only operates under about 2 psi max. Not much of a pipe to seal that kind of massive pressure. I'd just use "never-seeze" and not worry about a sealant. Just make sure the pipes are tight.

Unless I missed something the exhaust only operates under about 2 psi max. Not much of a pipe to seal that kind of massive pressure. I'd just use "never-seeze" and not worry about a sealant. Just make sure the pipes are tight.

Wow, I never thought such a simple question would lead to such an involved response. Thanks for all the input. My parts are exactly as pictured below in the photo posted by Maine Sail. The threaded coupler that connects the exhaust elbow to the mixing elbow is the part in question.

P.S. Where that hose connects to the elbow is a seawater connection. Doesn't that mean it needs a second hose clamp?

The parts are all new (I replaced the entire exhaust system last year) ordered from my Yanmar dealer. I have no idea whether the part has NPT threads or SAE threads or XYZ threads, I just know they were made to screw together. When I assembled them, I went to my local Auto Zone store and bought a small bottle of high temperature anti-sieze compound. It's silvery in color and has a consistency similar to toothpaste. I don't know the brand offhand, as it's on the boat and I'm trapped in my office at the moment. I do believe it was a lithium based product. I don't know if I have an exhaust leak here or not, but I do usually have a mild exhaust smell in my aft cabin after I shut down the engine, so I'm going back and taking another look at what I did when I replaced the entire exhaust system. I questioned whether I did the right thing by using anti seize, and whether there should be something else used here instead. If Mack Boring ships these with no sealant or compound, then I guess that's good enough for me. I'll just go to Harbor Freight and buy a bigger wrench and get another half-turn on this connection and call it good. Again, thanks for all your input. Regards, RobertYanmar ships engines like this one with no sealant on the tapered pipe threads.

P.S. Where that hose connects to the elbow is a seawater connection. Doesn't that mean it needs a second hose clamp?

sealant or never sieze?

Would you recommend using the Hercules Real-Tuff Teflon Sealant on the bolt threads also which attaches the exhaust flange to the exhaust mainifold? or use Never Seize?

You don't specifically say what "threads" you're talking about?

For NPT pipe threaded adapters I've been using Hercules Real-Tuff teflon thread sealant for over 20 years in this application. Seals well, does not dry out and parts will come apart easily in the future. Home Depot stocks it. If replacing an exhaust elbow or such I would strongly suggest schedule 80 pipe vs. schedule 40 for any fittings or nipples you may need..

Would you recommend using the Hercules Real-Tuff Teflon Sealant on the bolt threads also which attaches the exhaust flange to the exhaust mainifold? or use Never Seize?

- Status

- Not open for further replies.