So I started doing some work on a 1975 C22 that I purchased last fall and as I expected it has morphed into a restoration. One of the first things I did was power wash the inside of the boat and I noticed water trails on the outside of the hull running down the hull from behind the rub rail which is most likely where the screws that hold that joint together were leaking. I then stripped the hull completely and started on the keel and hardware and is still work in progress.

Since then I have gone to the extent of flipping the hull up side down to make it easier for me to re-core the deck. In the process of cleaning and preparing for the re-coring I noticed some small pieces of rotted wood that were knocked lose and falling out of the hull deck seam.

I am guessing that it would be close to impossible to remove all of that wood from that seam without completely removing the deck from the hull which is not something I would even attempt. I saw that some have cut out a strip of the fiberglass around the inside perimeter of the hull to deck joint to expose the wood then replaced, re fiberglassed then resealed the outside but thought someone may have had another option that might be an easier method. Maybe I could tape the underside and drill some holes and fill up with apoxy then through bolt it. I am also concerned about removing all those screws and having that seam pop apart. Not sure if that could happen but also do not want to find out.

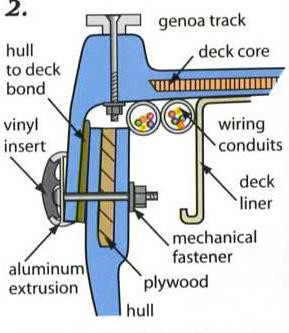

This is what the existing joint kind of looks like according to manual except it is not through bolted as they used screws into the wood and the toe rail is about 1/8 inch thick fiberglass and not solid as shown.

Below is a pic of that seam in my boat. There is a pocket that has plywood in the hull that is a couple of inches deep. The plywood is put in prior to assembling and can not be replaced .

Since then I have gone to the extent of flipping the hull up side down to make it easier for me to re-core the deck. In the process of cleaning and preparing for the re-coring I noticed some small pieces of rotted wood that were knocked lose and falling out of the hull deck seam.

I am guessing that it would be close to impossible to remove all of that wood from that seam without completely removing the deck from the hull which is not something I would even attempt. I saw that some have cut out a strip of the fiberglass around the inside perimeter of the hull to deck joint to expose the wood then replaced, re fiberglassed then resealed the outside but thought someone may have had another option that might be an easier method. Maybe I could tape the underside and drill some holes and fill up with apoxy then through bolt it. I am also concerned about removing all those screws and having that seam pop apart. Not sure if that could happen but also do not want to find out.

This is what the existing joint kind of looks like according to manual except it is not through bolted as they used screws into the wood and the toe rail is about 1/8 inch thick fiberglass and not solid as shown.

Below is a pic of that seam in my boat. There is a pocket that has plywood in the hull that is a couple of inches deep. The plywood is put in prior to assembling and can not be replaced .

Attachments

-

334.5 KB Views: 265