I know it has been a while but I just wanted to post an update on this new technology...

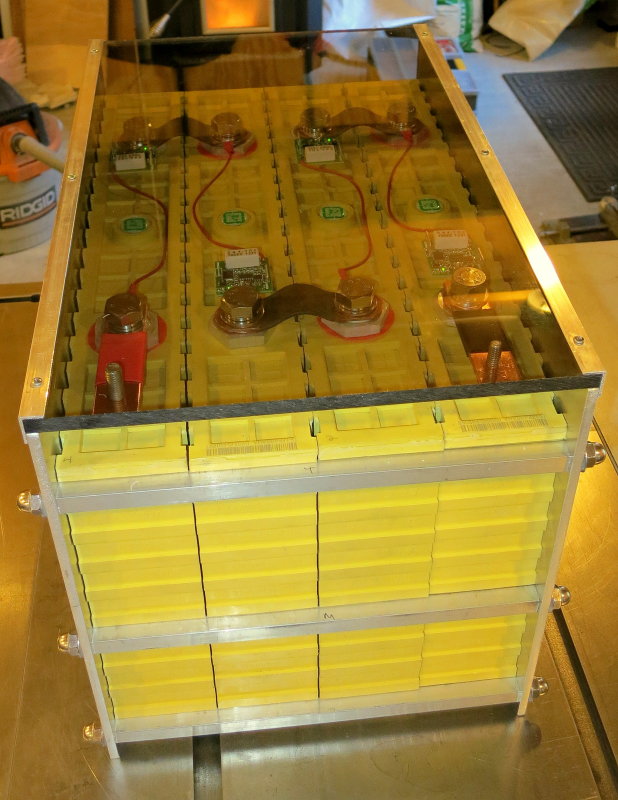

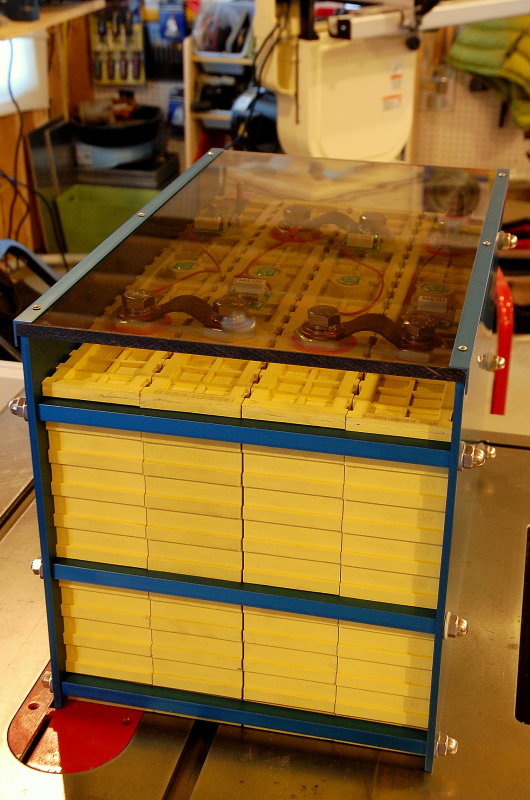

First, this bank has still yet to be "balanced" beyond my first top balancing 550 cycles ago. My BMS system is set up to NOT automatically

balance the cells. Considering I have yet to see many lead acid banks go 550 cycle on a boat, and none to 80% DOD and 550 cycles, this is proving to be less of an issue than you would have in equalizing lead acid batteries.

Of course a big reason for this steady balance is because I have employed

safe & sane charging voltages, I do not float, and I do not charge the batteries at temps below 32F.

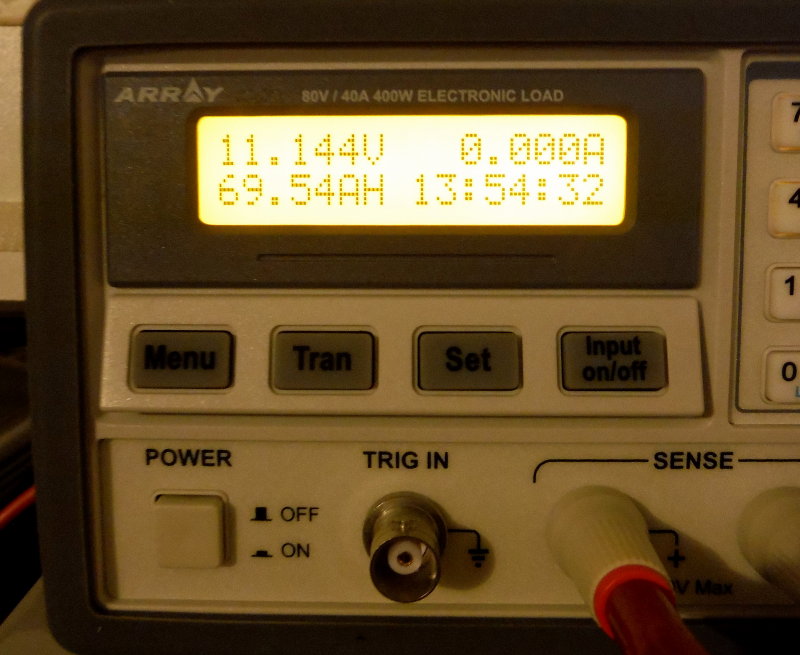

Just yesterday completed my 12th full capacity test, on this 400Ah rated bank, and this was at cycle number 550. This test was done at a 30A constant load the bank delivered 419.2 Ah's of capacity, this after 550 cycles with most of them being to 80% depth of discharge.

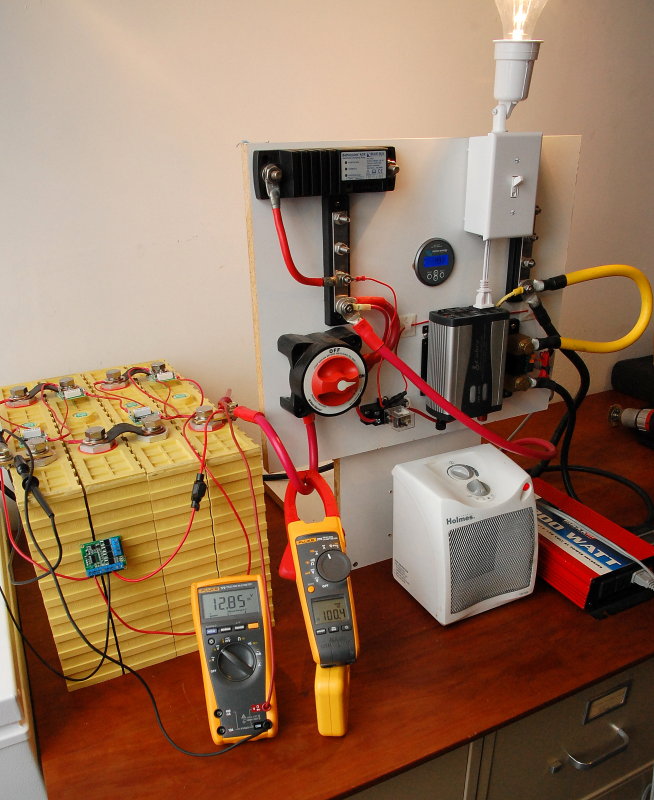

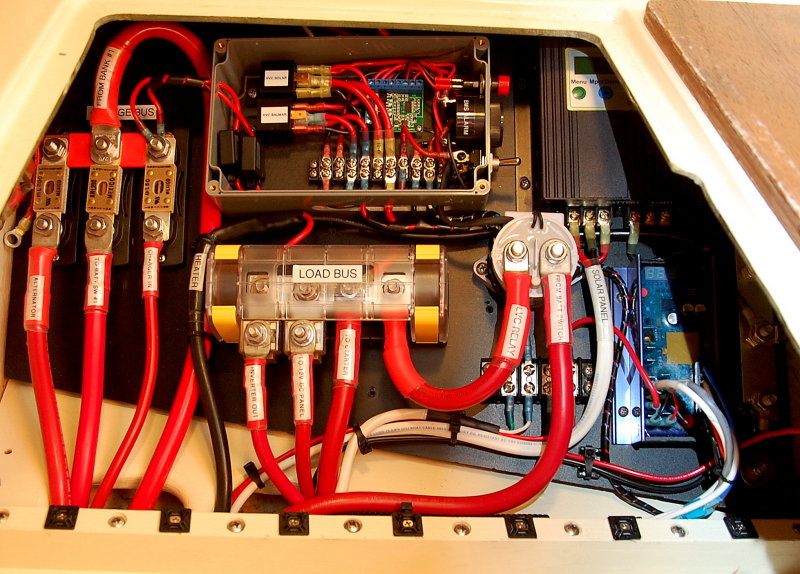

Pictured here is the 400Ah bank, a 60A lab grade power supply for charging and the 40A lab grade DC electronic load tester. Most of the smaller wires, in this spaghetti mess, are voltage sensing leads...

One of the things I offer my customers is 20 hour capacity testing for their expensive AGM or GEL batteries. Some even take advantage of it for flooded deep cycle. The only

true way to test a lead acid battery, for use as a deep cycle bank, is to physically capacity test it using industry standard testing procedures. The 20 hour test is most representative of the loads used on boats and thus a true 20 hour capacity test is what I use.

Many years ago I built an Ah capacity tester using an Ah counter, relays and DC loads but the accuracy was not as good as I would like because the DC load needs to stay steady the entire duration and this means manual manipulation. As the voltage decays the current increases thus changing the batteries discharge rate. With an non steady discharge rate, on lead acid batteries, this results in less than stellar accuracy. With LiFePO4 holding the current steady, while capacity testing the bank, is less critical because of the low Peukert effect.

A few years ago I had Mark Grasser, of Mark Grasser DC Solutions, build me a custom DC constant load tester for Ah capacity testing batteries at the 20 hour rate. This device worked well but still I wanted better control, easier set up and better overall accuracy.

I finally invested in a lab grade DC electronic load with battery testing capability. What a world of difference! The accuracy of these devices is amazing but they are not inexpensive.

What does all this have to do with LiFePO4?

At capacity test #12 (cycle #550) I switched this battery bank over to the new DC electronic load tester. All testing from this point forward will be done using this device. My new baseline was established at cycle #550 and the bank delivered an astounding 419.2 Ah's at a 30A constant load after 550 cycles!

I hesitate to

directly compare this capacity figure to the previous 11 capacity tests but it was very close to them and the bank delivered 419.2Ah's. From any 400Ah rated bank with 550 cycles on it, most to 80% DOD, this is something I would have never believed, had I not done the testing myself.

This bank is perhaps proving my initial cycle life skepticism as being wrong or misguided. While the discharge rate was lower, using the DC electronic load, the Peukert effect on this bank is also low. What really matters, or should, to myself or anyone choosing to use these as a house bank, is how many Ah's can you get at

your average house loads? The answer for this bank is in excess of 400Ah's even at 550 cycles into it...

I do believe I have lost

some capacity in those 550 cycles, but not much. The last test, using the old testing rig, delivered 423 Ah's.. Tests using the old method & equipment yielded anywhere from 421Ah's to a high of 426Ah's. This test was at 30A, not 100A, but with a higher accuracy piece of equipment and no inverter, just a pure DC load. Still this bank delivers more Ah capacity, at a 30A load, which is multiples more than our average on-board load, and that is good! We have 419 Ah's of capacity, at a 30A constant load, after 550 cycles. I'm a happy camper!!

Here is a close up shot of the data the DC electronic load captures when set to battery Ah testing mode. I set the capacity tester to 30A so as not to over heat it by running at full bore for 10+/- hours. The unit is rated at 40A but like anything electronic it likes to be run at less and will last longer doing so.

It should be noted that both my charge source and DC Electronic Load tester both utilize dedicated voltage sensing leads that do not carry any current. This means

accurate charging voltages physically measured at the battery terminals, and also accurate cut-off voltages, measured at the battery terminals.

The cut off voltage for this capacity test was set to 11.2V or 2.8VPC. A Cell Log 8 was used to trigger alarms if any cell dropped below 2.78V.

For comparisons sake here is a 100Ah AGM battery that is less than 3 years old and has under 100 cycles on it.. The owner claims to have never let the voltage dip below 12.1V...

Tester Screen Shot

Needless to say I am pretty happy with the results of my LiFePO4 experiment thus far. I still don't think it is ready for mass "prime time" DIY builds though..

For more in-depth information and back ground on LiFePO4, I have opened up my

yet to be completed article on LiFePO4 at the link below..

LiFePO4 Thoughts & Musings