Just curious, how long did the job take start to finish? That is a LOT of work.

Jim

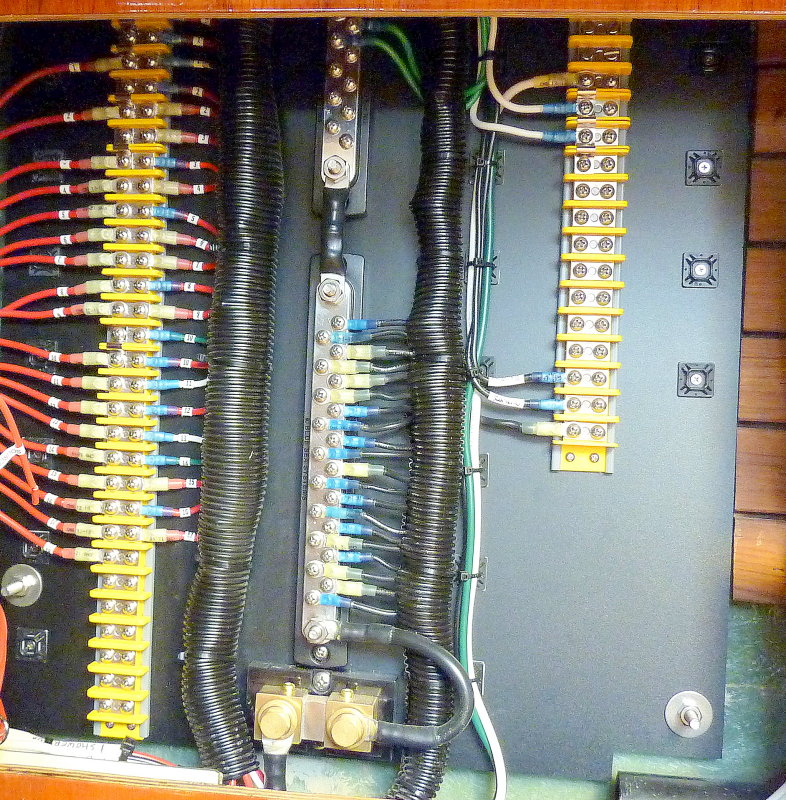

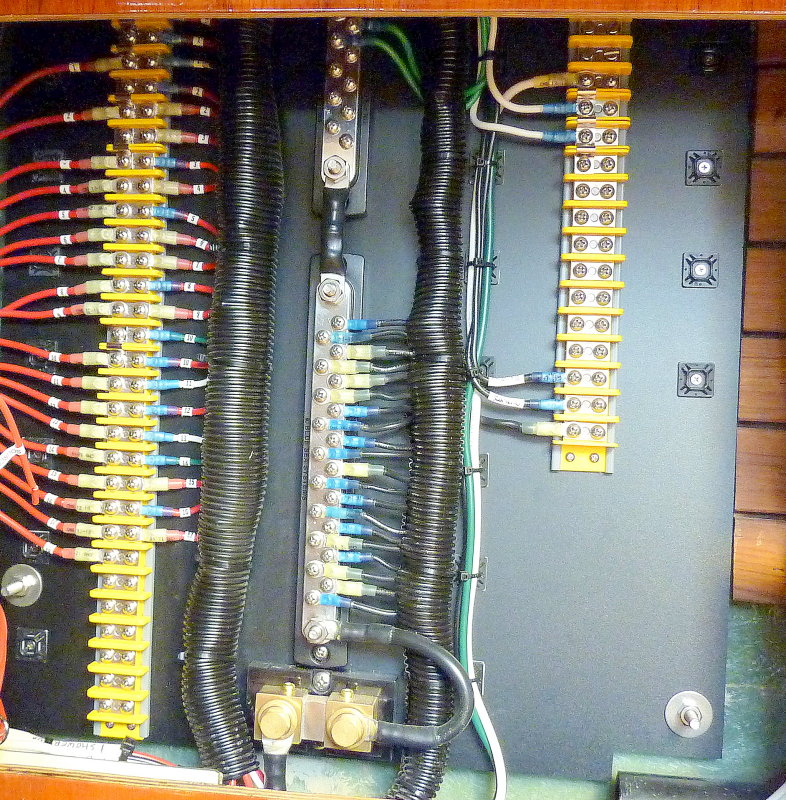

Probably about 300+ hours. Nearly the entire interior had to come out, things re-worked, panel built, back plane built, battery compartment re-designed etc. etc.. I started in late November.

Of course I also pulled out the engine, replaced the fuel tank, added a fuel polishing system, replaced & re-plumbed the water heater, replaced the VHF, added a RAM mic, R&R'd the manifold & exhaust elbow, changed the antifreeze, changed tranny fluid, re-bedded the chain plates, replaced the PSS bellows, replaced an incorrect vane type shower sump pump with the proper diaphragham type, re-finished some interior cabinetry, replaced standing rigging on & on & on.. Long winter but the fuel tank is what really put me behind, that and my real job and three year old.. For a while I was heading to the yard at 9:30 p.m. and coming home around 1-2 a.m. just to fit it all into the day..

A full re-wire is not a weekend project..

P.S. Just discovered yesterday that my less than 1 year old Nicro solar vent is dead... Gotta love boats...

Don't use 110V side, except for outlets & inverter, so I will finish that next winter.

Don't use 110V side, except for outlets & inverter, so I will finish that next winter.