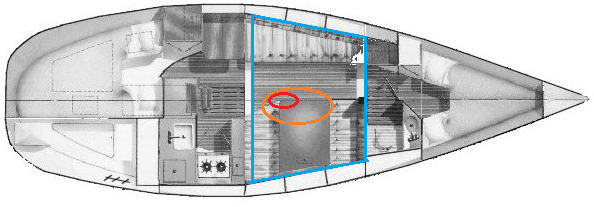

How are my searches yielding so little on this topic? It seems like rotten floors would be rampant on a boat forum. I have quite a large section of rotten plywood (with a most likely fake teak veneer) above the bilge section of the boat. I think I plan on replacing the center section of floor (outlined in blue). This section is bordered framed by fiberglass "bulkhead" that separate it from the bow berth and galley floor sections. Orange is comprimised floor and red is completely rotten floor. So the questions:

1. Does the furniture (couch on port, table/benches on starboard) have to be removed? How is this done?

2. Can I use a synthetic product like plastic deck boards? It seems silly to have plywood (even if it's treated) above the bilge. That just seems like the optimal environment for rot.

3. Any tips out there to help make this a success?

And a general question: why is there a grate at the foot of the stairs? It seems that hunter went out of their way to design it like that. Is it simply a floor mat of sorts to keep the interior clean?

1. Does the furniture (couch on port, table/benches on starboard) have to be removed? How is this done?

2. Can I use a synthetic product like plastic deck boards? It seems silly to have plywood (even if it's treated) above the bilge. That just seems like the optimal environment for rot.

3. Any tips out there to help make this a success?

And a general question: why is there a grate at the foot of the stairs? It seems that hunter went out of their way to design it like that. Is it simply a floor mat of sorts to keep the interior clean?