Refinishing swing keel

- Thread starter ambler

- Start date

Ambler, there are several posts in this forum from many of us who have done this job. Just use the search feature with key words like 'swing keel' & restoration or refurbishment... there is a ton of info here on this.

You are on the right track by chiseling off the marine growth and letting it dry out. Have you fully removed the keel from the hull yet? Once you do that you might want to get it the keel in doors and use a dehumidifier to help suck the moisture out. Tenting the keel with a dehumidifier helps too. Once its bone dry, get it to a sand blaster... trust me on this... don't let anyone talk you into 'grinding' it down DIY, total waste of time.

You are on the right track by chiseling off the marine growth and letting it dry out. Have you fully removed the keel from the hull yet? Once you do that you might want to get it the keel in doors and use a dehumidifier to help suck the moisture out. Tenting the keel with a dehumidifier helps too. Once its bone dry, get it to a sand blaster... trust me on this... don't let anyone talk you into 'grinding' it down DIY, total waste of time.

Thanks CloudDiver, your opinion about sandblasting came at just the right time. I was starting to think seriously about just grinding - the Catalina Direct DVD did this as an alternative to sandblasting. But "in my heart I know you're right." The grinder has taken off most of the blue (?epoxy) coating but there are still traces of blue left. Picture attached. I think grinding is just melting it into the surface. I think sandblasting is the best option. I really don't want to do this job again!

Yes, the keel is off the boat and in the garage. I can't imagine the hell of lying on my back and chiseling this off into my face. I've attached a pic of the amount that came off with a chisel. It's been almost 2 weeks and it's still sweating some moisture although its slowed down. The tent with a dehumidifier sounds like a good idea.

I've reviewed your posts about keel refinishing as well as your other projects. It makes me tired reading about all the work you've done. I've also read StingySailor's website. I'm grateful for the detail you've both included.

Yes, the keel is off the boat and in the garage. I can't imagine the hell of lying on my back and chiseling this off into my face. I've attached a pic of the amount that came off with a chisel. It's been almost 2 weeks and it's still sweating some moisture although its slowed down. The tent with a dehumidifier sounds like a good idea.

I've reviewed your posts about keel refinishing as well as your other projects. It makes me tired reading about all the work you've done. I've also read StingySailor's website. I'm grateful for the detail you've both included.

I'm having fairing problems. I'm following Stingy Sailor and CloudDiver's advice. Fairing the port side with the "Mexico" stamp went well. The keel was thick at the bottom as Stingy described and I took his advice to give up fairing when it became too thick. about a foot from the bottom. I've flipped it and the starboard side is more curved. The problem is that halfway down the keel it thickens and looks like Stingy's picture (https://stingysailor.com/2015/04/04/refinish-your-swing-keel-for-best-performance-part-3-fairing-2/ with caption "19% curve near the bottom"). This is 3 feet up from the tip, where it was only 1 foot up on the port side). There is only 5 foot (of 6.5 feet of total length) of keel exposed below the hull so that I'll only be fairing the top 2 feet. Should I partially fair the leading or trailing part of the lower part to get closer to the template?

Also, the iron continued to sweat water for 3 and a half months. There were only a few spots still sweating by mid August so I went ahead. One sandblaster said he had a 2 month wait and another said it would be a $200 minimum and couldn't say how much more until he finished work. Instead I bought a 20lb sandblaster for $60 from Harbor Freight and 80 grit garnet abrasive. It did a good job but took 2 days to complete. Despite setting up a "tent" with plastic sheet it was messy. I had to tape up the vents on my goggles to keep dust out. And any exposed skin ended up feeling like sandpaper. I was able to recover and reuse most of the abrasive. My biggest problem was that when the air is compressed the moisture of a humid Tennessee summer condensed. Despite a water trap enough moisture got past to gum up the abrasive. So I ended up shaking the tank to keep the abrasive flowing and stopping to clear blocks by back pressuring. The biggest lesson is that I don't ever want to redo this keel.

Also, the iron continued to sweat water for 3 and a half months. There were only a few spots still sweating by mid August so I went ahead. One sandblaster said he had a 2 month wait and another said it would be a $200 minimum and couldn't say how much more until he finished work. Instead I bought a 20lb sandblaster for $60 from Harbor Freight and 80 grit garnet abrasive. It did a good job but took 2 days to complete. Despite setting up a "tent" with plastic sheet it was messy. I had to tape up the vents on my goggles to keep dust out. And any exposed skin ended up feeling like sandpaper. I was able to recover and reuse most of the abrasive. My biggest problem was that when the air is compressed the moisture of a humid Tennessee summer condensed. Despite a water trap enough moisture got past to gum up the abrasive. So I ended up shaking the tank to keep the abrasive flowing and stopping to clear blocks by back pressuring. The biggest lesson is that I don't ever want to redo this keel.

It's an imperfect science to be sure -- my .02 and I followed a similar naca foil template -- definitely work the leading edge , it's a lot of fill to make the nose rounded, but worth the energy. Let the bottom 1/3 do its thing-- it's going to be wide of course but focus on the leading edge and generally smoothing across the chord : here's a look from the heavy end near the end of my work up in addition to the leading edge from the front. I spent a lot ( probably too much) time on the 3rdphoto-- that was a grind getting the nose rounded. And last photo you can see where I started from

Last edited:

found one more that might illustrate a bit better where to ignore and what to concentrate on: you can see the heavy build up just north of the keel pin hole in the picture and then again at the bulb you can see where I stopped sanding -- I spent all my time right there with the heaviest concentration on the smooth blob right in the center.... that was my biggest gaposis from the foil.

I took your advice pclarksurf and focused on the leading edge. My son is an aerospace engineer and he gave me the same advice. He says the leading part of the foil is responsible for the lift. The trailing portion serves to maintain smooth flow as the stream merges with the surrounding medium. I'm more interested in controlling leeway sailing to windward than in speed so the leading edge is where the money is.

When he was in school he said sailboat designers would use their wind tunnel to test keel designs. He said it was all very secret and no one was allowed in to see what they were doing.

When he was in school he said sailboat designers would use their wind tunnel to test keel designs. He said it was all very secret and no one was allowed in to see what they were doing.

I amazed how many people on this forum have refinished Catalina 22 swing keels. I've attached a picture. Can anyone spot the mistake? (I hope there's only one).

Attachments

-

728.9 KB Views: 311

It's true for sails too.I took your advice pclarksurf and focused on the leading edge. My son is an aerospace engineer and he gave me the same advice. He says the leading part of the foil is responsible for the lift. The trailing portion serves to maintain smooth flow as the stream merges with the surrounding medium.

95% of the known Catalina 22 universe sails around reasonably with perfectly nasty keels. The big gain is that the surface is SMOOTH, and stays smooth. So focus on that. The correct and shaped NACA profile is really a nice to have. Most owners would not notice if you replaced their keel with a 2x12 inch (smooth) plate section. For some it would be an improvement.

My $'s on the angle of your fill relative to the keel pin? might have transposed the leading edge there momentarily: I had a nice fat piece of painters tape to remind meI amazed how many people on this forum have refinished Catalina 22 swing keels. I've attached a picture. Can anyone spot the mistake? (I hope there's only one).

This was going to be my second guess after some more looking.My $'s on the angle of your fill relative to the keel pin? might have transposed the leading edge there momentarily: I had a nice fat piece of painters tape to remind me

View attachment 140990

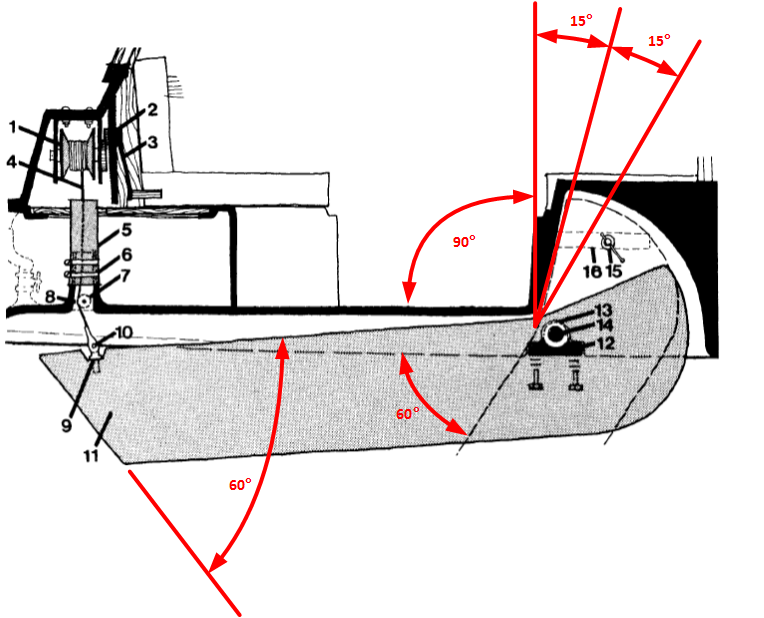

Full disclosure: I stole it from @$tingy Sailor but this view should be in everyone's reference library: