@JamesG161 I have one of those for years, used it once and it doesn’t work well. Better in concept than in practice. (Also not size appropriate for this thread).

How to remove 2 1/2 retaining nut?

- Thread starter sunlover

- Start date

Doesn’t appear to be new thru Hull fitting in photo. If you are trying to remove an old fitting to replace with a new one, grind off the mushroom portion of the fitting on the outside of the Hull and push the remaining piece thru the inside of the Hull. Don’t attempt to grind the entire mushroom, just the area immediately adjacent to the inside diameter of fitting. Once you have cut thru, the remaining mushroom ring can be removed from the outside Hull surface with a flat blade scraper or large screwdriver, tapping gently with a hammer. Takes five minutes with no damage to gelcoat. If you are not replacing it, you might try heating from inside to soften sealant and twisting/unscrewing from outside. The boat yard may have a deep socket that they will loan or rent to you; however, it will have to have a thin wall to engage the nut in that recessed area. Also going to need assorted extensions & angle adaptors to get a ratchet or breaker bar to unscrew it. Good luck, let us know outcome.Ideas? I keep thinking there must a sleeve like socket that would mate with it to tighten and loosen, but searches are empty.

I would consider drilling vertically thru the nut at mid flat. Start with a very small (1/16 long drill 6" or 12" are available) drill and do not drill past the lower nut surface. Center punch first and drill vertically. Enlarge hole with a slightly bigger drill. Do not drill thru the inside surface of the drill and damage the thru-hull threads. When you have the largest hole possible, use a sharp cold chisel and split the nut. Consider building up the depression before installing a new nut. Buy a new nut.

the new angle adapter just arrived.Unrelated to your immediate problem, but are you reusing the angled adaptor that attaches thru Hull fitting to valve or you replacing with a new one?

I replaced 8 above-the-water thru hulls on my boat last winter. I have a hard plastic pan in many locations where a thru hull was mounted…and I had to enlarge the hole in the liner in order to get a wrench (channel locks in my case) on the nut.

Greg

Greg

Its only Groco if its a new boat.....

I would turn the mushroom side from outside the hull. Usually no need to hold the inside nut to break the bond. If you do not have the special through-hull tool then take your set of open end/box wrenches and insert the box end of each into the mushroom until you find the one that fits inside and rests snugly against the mushroom inner tabs, then use an adjustable wrench to turn the box wrench shaft.

Is the through hull being replaced?

If so, then cut the pipe down so you can get a socket on the nut. Use a through hull wrench on the outside to hold the mushroom in place and remove the nut. Remove the through hull. Start fresh with new through hull.

I would verify the hull thickness. You might want to reinforce the through hull with a backing plate. A number of through hulls have been installed without backing plates on modern thin hulled boats. Failures are devastating and frightening when you reach down to open/close a stiff valve and expose a hole in the bottom of your boat.

A solid backing plate would necessitate opening the area of the pan.

If so, then cut the pipe down so you can get a socket on the nut. Use a through hull wrench on the outside to hold the mushroom in place and remove the nut. Remove the through hull. Start fresh with new through hull.

I would verify the hull thickness. You might want to reinforce the through hull with a backing plate. A number of through hulls have been installed without backing plates on modern thin hulled boats. Failures are devastating and frightening when you reach down to open/close a stiff valve and expose a hole in the bottom of your boat.

A solid backing plate would necessitate opening the area of the pan.

unless I bought the part and installed it.Its only Groco if its a new boat.....

Plumbers Faucet/Drain socket? They are relatively tall and thin walled, if you can find a set with big enough sizes

Modify a socket. Start with the correct sized, 2 & 1/2 inch, socket and cut it in half. Then weld in a piece of pipe or muffler tubing to make the socket deeper. This should be easy.

PS If the socket wall is to thick to fit in the recessed hole, grind in down. I've done his many times for other projects.

PS If the socket wall is to thick to fit in the recessed hole, grind in down. I've done his many times for other projects.

Last edited:

If you used silicone on the threads (use 4200 next time as it's less prone to failure) you can buy caulk remover products to weaken it. A breaker bar, ratchet with cheater bar, impact gun or decent drill should work without anything to weaken the bond. If all else fails see below for how I'd approach this

Pliers generally dont work well on nuts of this size. If you find the appropriate deep well socket and it is not deep enough, cut off some of the threads. If all else fails, cut the threads down so there's only about an inch left and then do one cut with the blade perpendicular to the fiberglass straight through the remaining threads and nut. Stop just before the fiberglass and use a screwdriver or chisel to break it the rest of the way. The nut is now in two pieces and will come off with a screwdriver. The remaining threads can be used to hammer the through hull out. If you're worried about hitting the hull, drill a hole the same size or slightly larger than the threads in a small piece of 1/2" plywood and slip it over the thru hull. All of this metal cutting will be pretty easy with an angle grinder with a cutting blade. If you're new to using one do some practice cuts, add some wood around the fiberglass in case the tool slips, see how it reacts when doing cuts at various angles and do use safety glasses/goggles.

I found during my rebedding project that 4200 and silicone come off pretty easily. You may want to buy some debond if it's 5200

Pliers generally dont work well on nuts of this size. If you find the appropriate deep well socket and it is not deep enough, cut off some of the threads. If all else fails, cut the threads down so there's only about an inch left and then do one cut with the blade perpendicular to the fiberglass straight through the remaining threads and nut. Stop just before the fiberglass and use a screwdriver or chisel to break it the rest of the way. The nut is now in two pieces and will come off with a screwdriver. The remaining threads can be used to hammer the through hull out. If you're worried about hitting the hull, drill a hole the same size or slightly larger than the threads in a small piece of 1/2" plywood and slip it over the thru hull. All of this metal cutting will be pretty easy with an angle grinder with a cutting blade. If you're new to using one do some practice cuts, add some wood around the fiberglass in case the tool slips, see how it reacts when doing cuts at various angles and do use safety glasses/goggles.

I found during my rebedding project that 4200 and silicone come off pretty easily. You may want to buy some debond if it's 5200

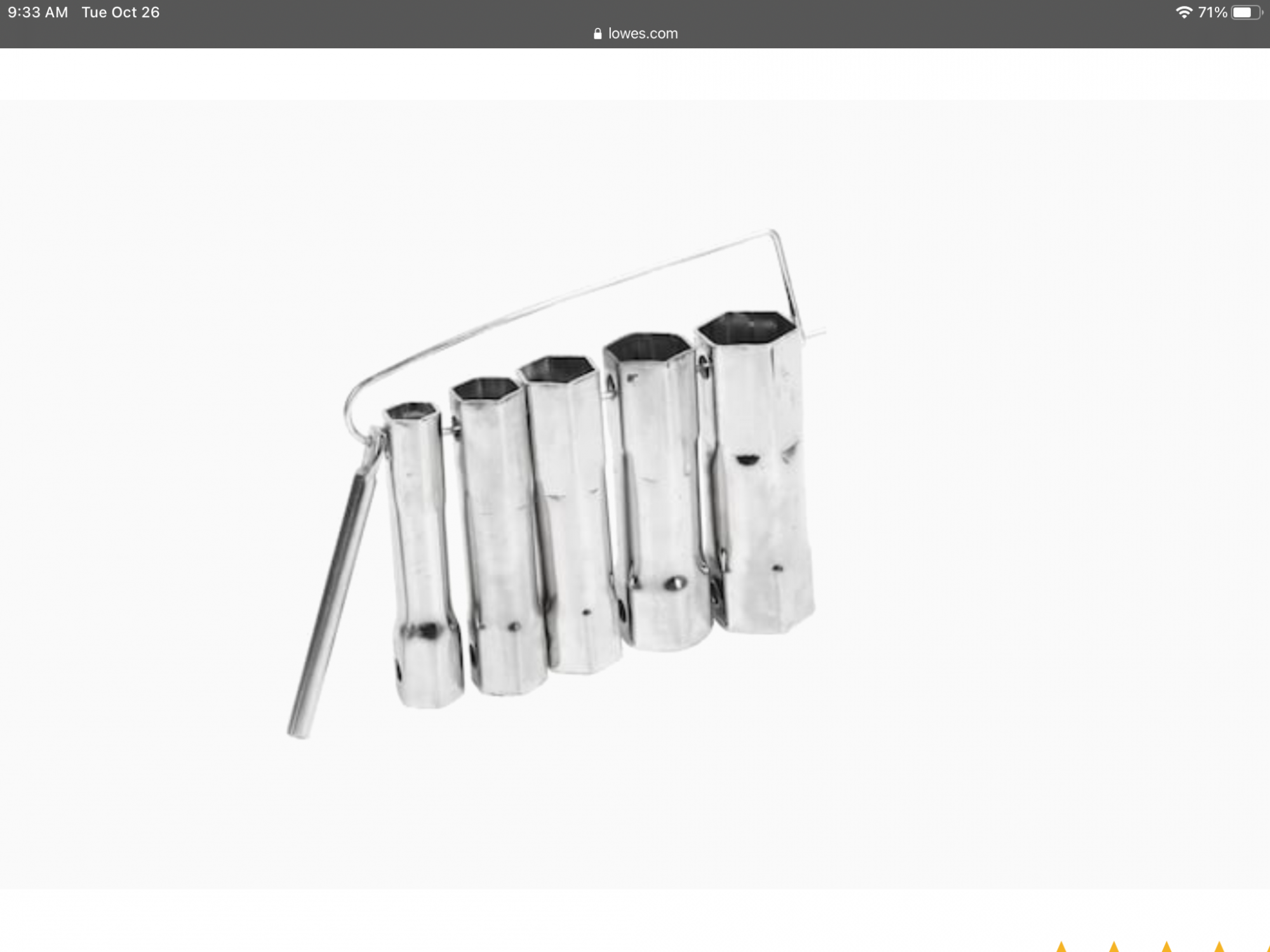

those would be perfect. so far, I can't find anything in the right size. I would think that groco would have them.Plumbers Faucet/Drain socket? They are relatively tall and thin walled, if you can find a set with big enough sizesView attachment 199542

Buy the groco socket if you can. I imagine the right tool will make this a non-trivial task. Money spent on the right tool is going to be cheaper than buying the wrong tools not to mention time and frustration

I looked through an older online Groco catalog. I didn't see a socket offered and I don't think 2 & 1/2 inch is the correct size socket.

Perhaps this adjustable wrench:

adjustable plumbers wrench

Also, you will probably need the internal wrench for the thru hull as well.

BTW, you don't use silicone on thru hulls.

adjustable plumbers wrench

Also, you will probably need the internal wrench for the thru hull as well.

BTW, you don't use silicone on thru hulls.

Auto part stores also have some large sockets in their rental inventory for FWD axle replacement. They're typically in the 27-32mm range IIRC. They're usually 1.5-2" deep