We recently removed our 13 year old PSS system on our Catalina 350. It didn't fit right and we're lucky it didn't fail for a number of reasons. Anyways we went back to the original stuffing box system. We have put about 10 hours on it and it gets to hot to hold onto. The shaft spins freely by hand. It is backed almost all the way off the threads and once it heats up to 130-145 degrees no water drips out at all. It really shouldn't drip at the docks but that's where I start because even at 4 drops a minute it still gets up to 130-145 degrees within about 20 minutes. I've asked the boatyard if the correct number of rings (3) were installed, cut correctly and offset from one another. All were yes answers. They told me don't worry it won't hurt the shaft but they also said I should be able to hold onto the stuffing box. There is no way to do that, it's so hot. I'm at wits end and will try again in a few days to readjust. Any ideas out there? Thanks Rick

New stuffing box overheating

- Thread starter bertram

- Start date

Or a LasDrop Gen II if you didn't like the PSS.

Take a gander at Rod's writeup. He addresses temp spikes

Take a gander at Rod's writeup. He addresses temp spikes

Re-Packing A Traditional Stuffing Box - Marine How To

The Stuffing Box (click any image to see a larger version) While digging around in some old boat parts boxes I found a stuffing box from an older sailboat. I though it would be a good time to rig it up

marinehowto.com

I have experienced this problem in the past. Here are my thoughts on it:We recently removed our 13 year old PSS system on our Catalina 350. It didn't fit right and we're lucky it didn't fail for a number of reasons. Anyways we went back to the original stuffing box system. We have put about 10 hours on it and it gets to hot to hold onto. The shaft spins freely by hand. It is backed almost all the way off the threads and once it heats up to 130-145 degrees no water drips out at all. It really shouldn't drip at the docks but that's where I start because even at 4 drops a minute it still gets up to 130-145 degrees within about 20 minutes. I've asked the boatyard if the correct number of rings (3) were installed, cut correctly and offset from one another. All were yes answers. They told me don't worry it won't hurt the shaft but they also said I should be able to hold onto the stuffing box. There is no way to do that, it's so hot. I'm at wits end and will try again in a few days to readjust. Any ideas out there? Thanks Rick

Although you are seeing 4 drops a minute, I'll bet you that those drops are not coming from where the shaft exits the stuffing box but rather are coming out the back of the stuffing box nut. You said, "It is backed almost all the way off the threads." In an attempt to get it to cool, you probably kept backing off the nut until water finally showed up, but it is not coming from where you want. These drips, if coming out of the aft end of the nut and not at the point where the shaft exits the nut, will run down the underside of the box and eventually drip, but they will not be doing anything to cool the shaft. What you should do is run it at speed and then look carefully at the shaft where it exits the packing nut while you do. You should be seeing some weeping or glistening of water there. If it is bone dry, that's your problem. It does not matter what other dripping you might see: the water you need to cool the shaft is not there.

As for why this might be the case: The yard may have packed the box wrong, or they may have crammed in packing that is too large. Properly sized packing should go in snugly but not too snugly. If you have to "hammer it in," it's too tight. But you don't want it too loose, either. So just snug, but it should not be overly difficult to install. I would ignore anything the boatyard says and just redo the packing yourself, from scratch. Then you will know how it was done.

130 to 145 degrees is certainly hot but is not likely to damage anything. Nevertheless, I agree that it suggests something is not quite right, as a properly adjusted box should be cooler than this. (Mine certainly is.) So I think you are wise to get to the bottom of it.

Here is an excellent article by MaineSail on how to pack a traditional stuffing box.

You do not mention what kind of packing you are using. On my boat I use the GoreTex synthetic packing. A common misconception about this packing is that you should adjust it so that it is "dripless" when running. As Mainesail has correctly pointed out, it is not "dripless" but rather "drip less." ALL forms of packing require at least some lubrication to avoid overheating. Do not let anyone try to convince you otherwise. An ideal setting with the GoreTex is no drips while at the dock/at rest and a very slight weeping or "glistening" of water at the shaft to packing nut interface. That is as good as it gets--at least for reliable operation. (As Mainesail has also noted, while it is possible to get it just exactly at the point where it doesn't drip but doesn't overheat, that setting is unstable and can lead to unpredictible overheating when you are not expecting it. I have also experienced this before I knew better.) If you have to err, let it drip slightly vs. cranking up the nut too tight.

Though this may be more information that you really need to know, because this "dripless" notion is so widely found on internet fora, I'm copying below an e-mail I received from an engineer at Buck Algonquin, a stuffing box manufacturing company. In it, he gives a nice rundown on the various types of packing, their pros and cons, and also makes it very clear that the all require at least some amount of water to keep the shaft lubricated.

Hope this helps,

Alan

[E-mail from Buck Algonquin engineering below]

From: [ADDRESS REMOVED] On Behalf Of Steve Gaston

Sent: Saturday, May 08, 2010 9:57 AM

To: Alan Gomes

Subject: Re: Packing box issues

Dear Alan,

95% of my packing box questions revolve around the goretex graphite based packing. It is good packing. However, most people misinterpret the instructions and believe it is drip free. All three material (graphite, Teflon, and flax) have their drawbacks.

Flax. low cost. temperature tolerance minimum. abrasive. Does require water for cooling and lubrication.

Teflon. medium cost. High temperature tolerance (packing only). mildly abrasive. Does require water for cooling and lubrication.

Graphite. higher cost. High temperature tolerance. least abrasive. Does require water for cooling and lubrication.

The common theme here is they all require water for cooling. I do not believe you will get a much better setup than the goretex running at the 130 degrees. The temperature will vary with the amount of water drip through the packing and the shaft speed.

The other components have a reasonably high tolerance to heat. The packing box hose is made of the same materials as marine exhaust hose. The bronze and stainless are not a relative heat consideration.

The abrasion factor would be the other consideration. Since the goretex has the least abrasion impact, it would be the better choice.

I hope this helps.

Best Regards.

Steve

Last edited:

Sounds to me like the boat yard used the wrong size packing. Otherwise, you could have a badly misaligned engine and the shaft is wearing on the inside of the new gland, causing the heat.

Personally, I wouldn't have any system that required a haul out if it failed, like the dripless glands.

Personally, I wouldn't have any system that required a haul out if it failed, like the dripless glands.

Most likely the only way to correct this problem is to learn to pack the gland yourself. As previous posts here show, many boatyards are notoriously poor. I would suggest this is your problem.

Even if your boat is still in the water, packing it wet is not a formidable problem. However, I would suggest having an assistant nearby the first time you do this.

Even if your boat is still in the water, packing it wet is not a formidable problem. However, I would suggest having an assistant nearby the first time you do this.

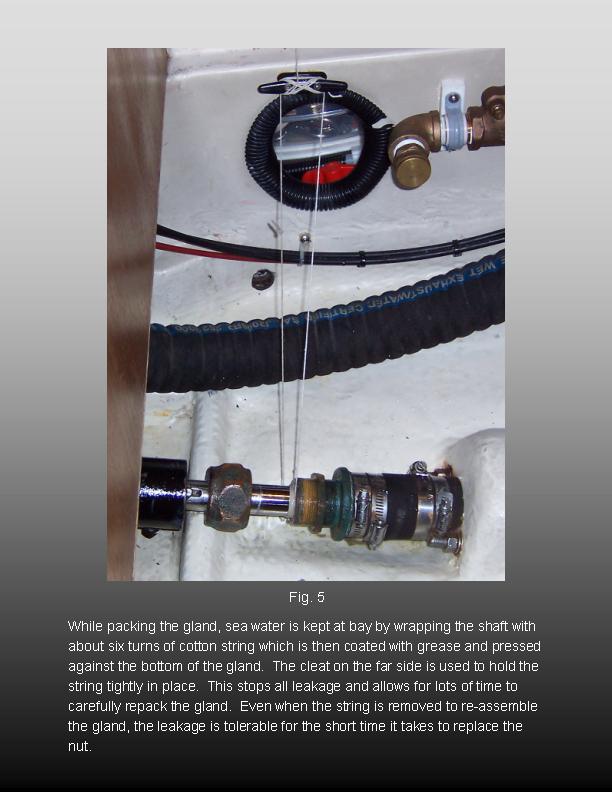

This is a very clever solution, but it may or may not be needed depending on the rate of flow in relation to your bilge pump. On my last three boats, my bilge pumps easily kept up with the flow and so this would have been unnecessary. But your boat may be different from mine, so keeping some string handy (with some attachment points) seems like a good idea, at least the first time you do it. This looks like an elegant and simple way of handling it if you find it necessary to do so.Most likely the only way to correct this problem is to learn to pack the gland yourself. As previous posts here show, many boatyards are notoriously poor. I would suggest this is your problem.

Even if your boat is still in the water, packing it wet is not a formidable problem. However, I would suggest having an assistant nearby the first time you do this.

View attachment 179854

@Ralph Johnstone likes to have a cleat handy in case there's a need to tie some(one) thing off.

This is probably spectacularly unhelpful for people having an overheating problem, but here goes. I have a traditional stuffing box that I repacked twice between 2004 and 2015. It has never felt even remotely warm to the touch, even when running the engine at normal 2800-3000 RPM. I repacked using teflon packing, and try to get a drip every 15-30 seconds, but sometimes I don't see any dripping and I sill don't get any heat buildup. The shaft looks fine under the stuffing box...

I repacked my traditional stuffing box over the winter with GTO.

I was out this weekend with crew, and we motored back about 3 NM after the wind died (and the biting flies came out).

Since I had crew, I went below to check the engine, stuffing box, etc. I touched the stuffing box, and it was hot to the touch. I grabbed my IR thermometer and it read 150F at the packing nut.

I don’t usually motor more than 15 minutes into and out of my berth, And have only sailed about 3 times thus season so far, so haven’t really Noticed the stuffing box.

Today I went to the boat and backed the nut off about a quarter of a turn. No dripping when the prop wasn’t turning. Fired up the 2GM20, tied the boat up tight and put her in gear @about 2000 RPMs. 20 minutes and the nut was about 90 degrees. Ambient temperature today in the 80’s, but water temp about 65F.

I will monitor next time out and may have to back off another 1/4 turn, but I think I can get it dialed In.

Greg

I was out this weekend with crew, and we motored back about 3 NM after the wind died (and the biting flies came out).

Since I had crew, I went below to check the engine, stuffing box, etc. I touched the stuffing box, and it was hot to the touch. I grabbed my IR thermometer and it read 150F at the packing nut.

I don’t usually motor more than 15 minutes into and out of my berth, And have only sailed about 3 times thus season so far, so haven’t really Noticed the stuffing box.

Today I went to the boat and backed the nut off about a quarter of a turn. No dripping when the prop wasn’t turning. Fired up the 2GM20, tied the boat up tight and put her in gear @about 2000 RPMs. 20 minutes and the nut was about 90 degrees. Ambient temperature today in the 80’s, but water temp about 65F.

I will monitor next time out and may have to back off another 1/4 turn, but I think I can get it dialed In.

Greg

Also helps my equilibrium after one too many@Ralph Johnstone likes to have a cleat handy in case there's a need to tie some(one) thing off.

The difference between doing it yourself and having it done by the assistant to the apprentice yard apeI have a traditional stuffing box that I repacked twice between 2004 and 2015. It has never felt even remotely warm to the touch, even when running the engine at normal 2800-3000 RPM.