todays lesson: fast, cheap or easy. pick two!!

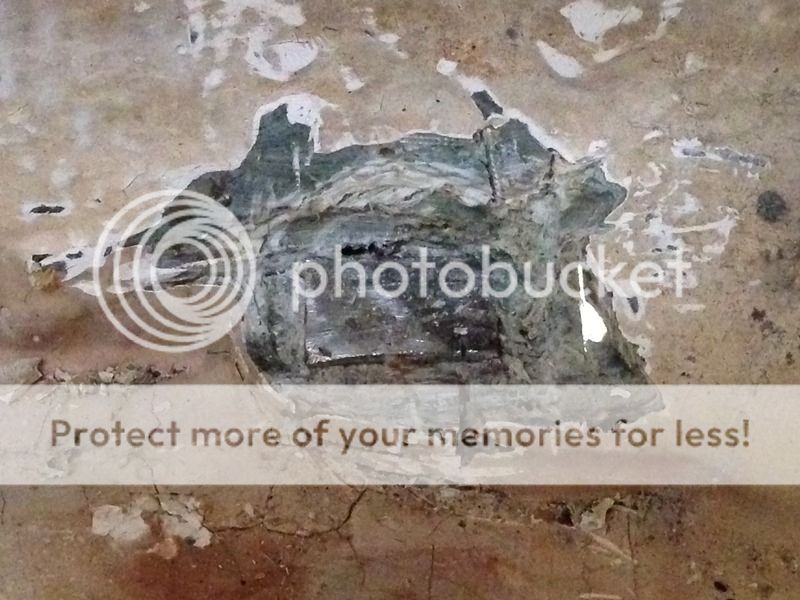

I have always used quality paints on my projects in the past (PPG for auto or Awlgrip/awlcraft for boats)... I decided to cheap out on this one since this was supposed to be a budget resto. I am using rustoleum marine topsides paint and rolling it. research indicates that just rolling results in a better finish than rolling and tipping with this particular paint. well... I am not happy. you have to wait 24 hrs before the next coat, sand with 220 then re-coat. I just finished the 3rd coat and feel like I need at least one more. and its got a decent amount of orange peel!! I am wishing now I would have used a better paint (even automotive) and sprayed it... live and learn right?

I have always used quality paints on my projects in the past (PPG for auto or Awlgrip/awlcraft for boats)... I decided to cheap out on this one since this was supposed to be a budget resto. I am using rustoleum marine topsides paint and rolling it. research indicates that just rolling results in a better finish than rolling and tipping with this particular paint. well... I am not happy. you have to wait 24 hrs before the next coat, sand with 220 then re-coat. I just finished the 3rd coat and feel like I need at least one more. and its got a decent amount of orange peel!! I am wishing now I would have used a better paint (even automotive) and sprayed it... live and learn right?