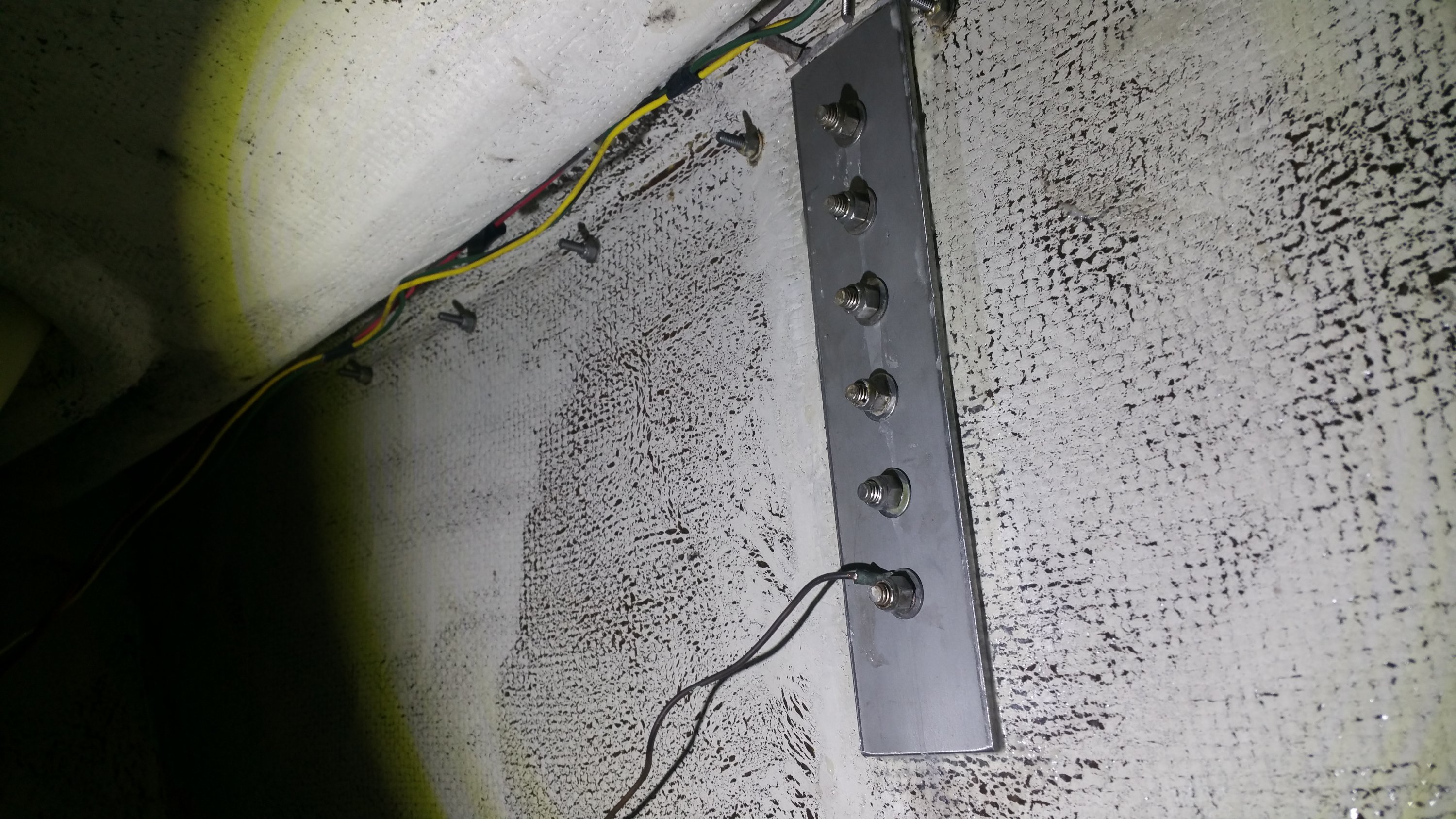

On my not-so-urgent project list was replacing the teak backing for the backstay chainplate. I had a new one fabricated out of 1/4" stainless, slightly larger than the teak one. I bedded it in thickened epoxy and used butyl tape to bed the chainplate and bolts. The old one was in far worse shape than it appeared when it was in place, especially the back side.

The new one is certainly overkill, but hopefully that can be permanently crossed off the project list!

The new one is certainly overkill, but hopefully that can be permanently crossed off the project list!

O'day 34 backstay backing plate

- Thread starter Sefuller

- Start date

If I recall correctly, the backing plate for the backstay on my 1987 O'day 35 is stainless.

I've been in this location, and it is not pleasant. The easiest way to get in here is to remove the liner from the spare propane locker (starboard), To remove that involves removing the engine compartment access door and the rear panel from the rear quarterberth.

That wire is a bonding wire. It runs from one of the bolts that secure the backstay through the middle of the bilge compartment and eventually bolts onto one of the keel bolts. There are other ones that comes from; the mast, the port upper shroud, the starboard upper shroud, and the forestay. Here is a picture of where they all come together under the base of the mast.

Along the route that each of these wires takes, there are splices which connect to the engine, and each of the bronze through hulls.

I have removed these connections on my boat, as I do not want to risk galvanic corrosion of my through hulls.

I've been in this location, and it is not pleasant. The easiest way to get in here is to remove the liner from the spare propane locker (starboard), To remove that involves removing the engine compartment access door and the rear panel from the rear quarterberth.

That wire is a bonding wire. It runs from one of the bolts that secure the backstay through the middle of the bilge compartment and eventually bolts onto one of the keel bolts. There are other ones that comes from; the mast, the port upper shroud, the starboard upper shroud, and the forestay. Here is a picture of where they all come together under the base of the mast.

Along the route that each of these wires takes, there are splices which connect to the engine, and each of the bronze through hulls.

I have removed these connections on my boat, as I do not want to risk galvanic corrosion of my through hulls.

Note that if you remove the connection from the through hull, you are increasing the probability of damage to the vessel in the event of a lightning strike. On the other hand, one could argue that you are decreasing the likelihood of a lightning strike. An absolute best-practice on lightning protection has, IMHO, not yet been determined.

The process for replacing the seacock is well documented at Maine Sail's site, and I used his method with 3/8" G-10 backing plates. Note that the 90º fitting should be INWARD of the seacock, and if you have a "scoop with grate" through hull it should be removed, as these make great nurseries for mussels.

A client of mine has a "scoop with grate" seacock which connects to a 90º fitting, which then connects to the seacock on his O'35. He has asked me to straighten this out for him while his boat is on the hard. Because his yard does not allow me to work on his vessel, I have had to tell him to do it through the yard (and I'm pretty sure that they will screw it up).

The process for replacing the seacock is well documented at Maine Sail's site, and I used his method with 3/8" G-10 backing plates. Note that the 90º fitting should be INWARD of the seacock, and if you have a "scoop with grate" through hull it should be removed, as these make great nurseries for mussels.

A client of mine has a "scoop with grate" seacock which connects to a 90º fitting, which then connects to the seacock on his O'35. He has asked me to straighten this out for him while his boat is on the hard. Because his yard does not allow me to work on his vessel, I have had to tell him to do it through the yard (and I'm pretty sure that they will screw it up).

Last edited:

I removed that strainer and ball valve on mine also much like the picture above. Note the strainer ID is 1/2 inch and IIRC the raw water pump inlet is larger so the strainer limits the cooling water flow, add a few critters growing in there and a few layers of paint in the slits and you have a potential for overheating.

On my boat, removing the quarterberth panel results in the same access as going through the cockpit locker (without removing any panels). Still have to scrunch around a propane locker......

I've been in this location, and it is not pleasant. The easiest way to get in here is to remove the liner from the spare propane locker (starboard), To remove that involves removing the engine compartment access door and the rear panel from the rear quarterberth.

...

We do have the luxury of being in fresh water (boat has always been on the Great Lakes) and our corrosion issues are virtually non-existent. We had friends who left the Great Lakes and cruised the east coast and Bahamas, and I know it was a whole different way of thinking - fittings, electrical, water systems...I used plywood to replace it but if I had the material on hand I'd go with g10. Any metal can corrode (unless you use gold or platinum) and wood can rot. G10 you will never worry again.

The hoses run to my Rule 2000 Gold electric bilge pump, which discharges out the transom. That is not a through deck fitting, it is an anti-siphon loop.What are those hoses and is that a thru deck fitting?

THANK YOU FOR THAT!!! I have a piece of 3/8" G10, that will do PERFECTLY!I used plywood to replace it but if I had the material on hand I'd go with g10. Any metal can corrode (unless you use gold or platinum) and wood can rot. G10 you will never worry again.