Fixed my little alternator problem which is a story in itself. Machinist had to put an insert in an ovalized hole in the lower mount. Machinist couldn't get the mating surface square so I took it home and drilled a 5" hole in a piece of plywood and set the alternator pulley in it so it sits square and chucked up a 1" flat grinder wheel for a dremel tool in the drill press and ground it flat. Gotta wonder......Course I had to fire things up to make sure it worked. Engine started almost immediately with some grey smoke. So, I have some tweaking to do with the injector pump rack adj. It hadn't been started in two wks...I'm happy.....

MD17C rebuild

- Thread starter Mark Maulden

- Start date

Mark,Maybe your bro could make me one......

I saved my old exhaust elbow. We need to compare to see if your boat uses the same one. I was thinking a shop could braze the holes to repair the used elbow or I could send the elbow down to my brother to see if he could fabricate something. The new elbow cost me over $200. I don't think I'll have this motor long enough to wear it out.

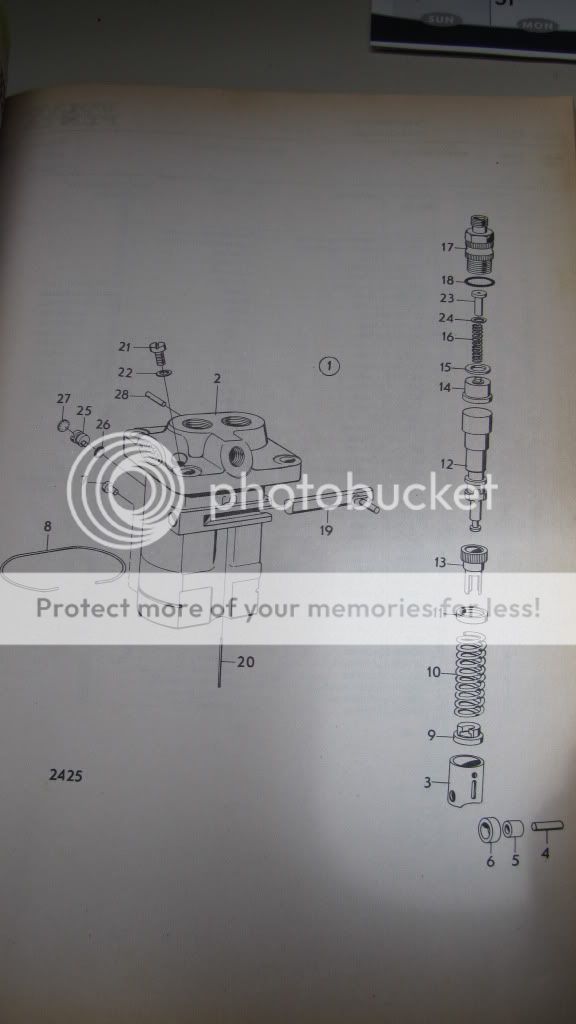

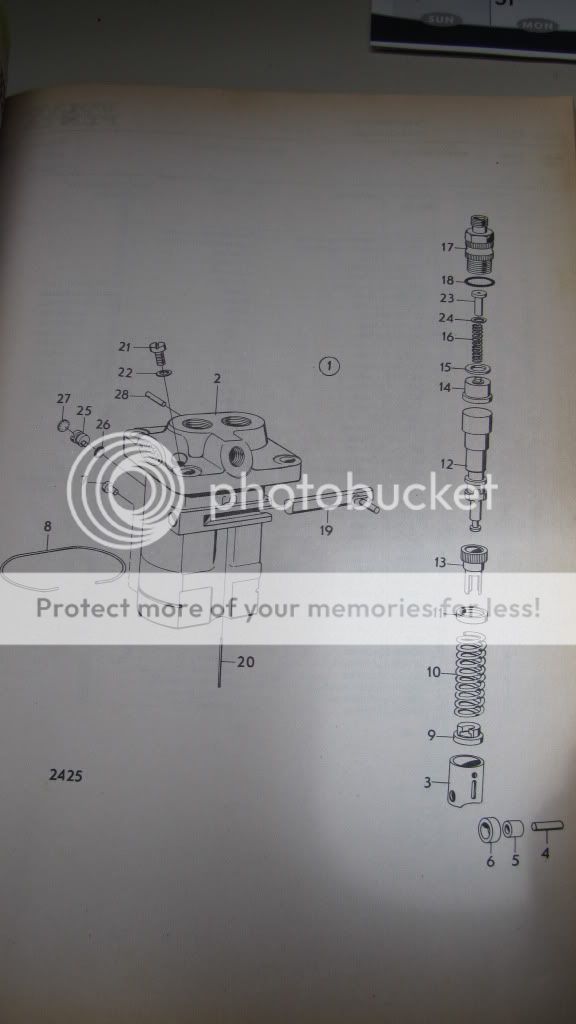

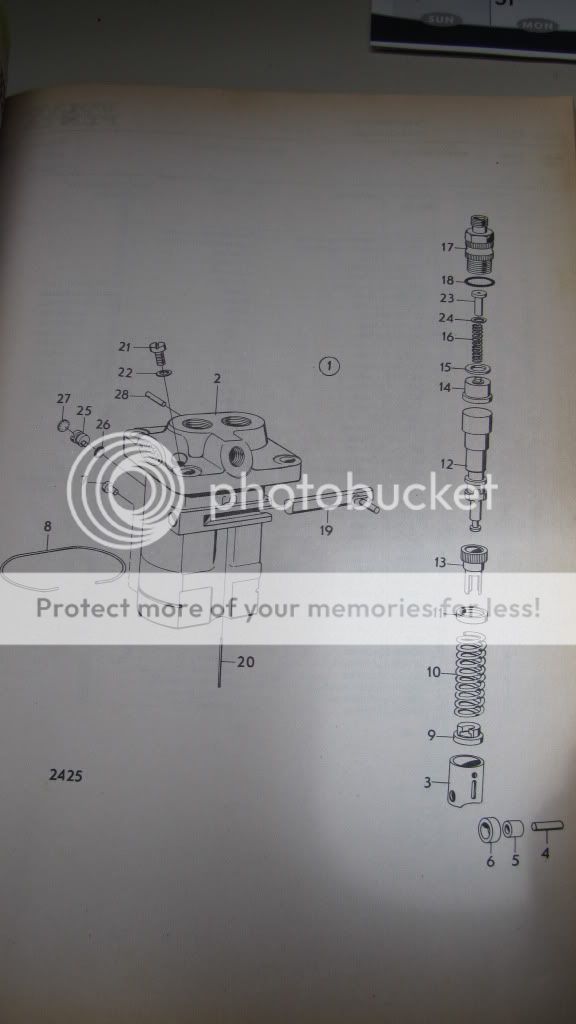

I ordered the O-rings and some copper washers to see if I could fix the problem without removal of the whole pump. They are numbers 18 and 15 in the parts diagram

Scrubbed top of injector pump with WD-40 and a tooth brush to clean it up. Removed fuel supply line to top of injector pump (17mm wrench). Removed injector lines off injectors and injector pump (17mm wrench) Removed fuel return line (10mm wrench), Remove oil filler cap assembly (it was in the way). Shove paper towel down the hole uncovered by the oil filler cap to keep crap from gettin' in the gears.

Remove a little keeper dealy-bob between two of the injector delivery nozzle caps. I think this dealy-bob keeps the center cap from turning when you're pulling off the injector lines because you can't get a wrench on it to hold it. 19mm deep well socket to remove each fuel delivery valve cap. There is a spring under there, but it doesn't go boing when you pull the cap. Under the cap is the O-ring and a copper gasket that needs to be replaced. Here is a parts diagram. Takes about 1.5 hours to disassemble and clean. Takes about an hour to put it back together.

Put it together this morning and it fired right up. No leaks. Hurray, we're going out to Hope Island to enjoy this weather while it lasts.

Scrubbed top of injector pump with WD-40 and a tooth brush to clean it up. Removed fuel supply line to top of injector pump (17mm wrench). Removed injector lines off injectors and injector pump (17mm wrench) Removed fuel return line (10mm wrench), Remove oil filler cap assembly (it was in the way). Shove paper towel down the hole uncovered by the oil filler cap to keep crap from gettin' in the gears.

Remove a little keeper dealy-bob between two of the injector delivery nozzle caps. I think this dealy-bob keeps the center cap from turning when you're pulling off the injector lines because you can't get a wrench on it to hold it. 19mm deep well socket to remove each fuel delivery valve cap. There is a spring under there, but it doesn't go boing when you pull the cap. Under the cap is the O-ring and a copper gasket that needs to be replaced. Here is a parts diagram. Takes about 1.5 hours to disassemble and clean. Takes about an hour to put it back together.

Put it together this morning and it fired right up. No leaks. Hurray, we're going out to Hope Island to enjoy this weather while it lasts.

saw your email. That hole is really something. Not sure if you could braze it but a good machinist or like could tell ya. Maybe JB weld? Mine looked good and got tanked when all the other parts got tanked. Maybe I should tap it with my little rock hammer......Mark,

I saved my old exhaust elbow. We need to compare to see if your boat uses the same one. I was thinking a shop could braze the holes to repair the used elbow or I could send the elbow down to my brother to see if he could fabricate something. The new elbow cost me over $200. I don't think I'll have this motor long enough to wear it out.

Great!! Glad to see you made progress. My delivery valves were sticking....BTW, I"m sure you're aware that the diagram above is NOT for an MD17. Little parts are probably the same though......Went out to Lopez Is and raised sails. First time since new rig. No wind....I ordered the O-rings and some copper washers to see if I could fix the problem without removal of the whole pump. They are numbers 18 and 15 in the parts diagram

Scrubbed top of injector pump with WD-40 and a tooth brush to clean it up. Removed fuel supply line to top of injector pump (17mm wrench). Removed injector lines off injectors and injector pump (17mm wrench) Removed fuel return line (10mm wrench), Remove oil filler cap assembly (it was in the way). Shove paper towel down the hole uncovered by the oil filler cap to keep crap from gettin' in the gears.

Remove a little keeper dealy-bob between two of the injector delivery nozzle caps. I think this dealy-bob keeps the center cap from turning when you're pulling off the injector lines because you can't get a wrench on it to hold it. 19mm deep well socket to remove each fuel delivery valve cap. There is a spring under there, but it doesn't go boing when you pull the cap. Under the cap is the O-ring and a copper gasket that needs to be replaced. Here is a parts diagram. Takes about 1.5 hours to disassemble and clean. Takes about an hour to put it back together.

Put it together this morning and it fired right up. No leaks. Hurray, we're going out to Hope Island to enjoy this weather while it lasts.

Well, the only reason(s) I did it was I was pretty sure the crank/cam were good as I still had good oil pressure so I didn't have to remove the block. I did 95% of the labor myself and I found the parts which are actually pretty plentiful if you know where to look. In the beginning, I wasn't planning on replacing liners/pistons, but hey, it's a boat!!! Been running great and absolutely no oil burn. I haven't yet started it in colder weather yet since I've been repacing a water tank. But, I should see how it starts in colder WX.......Be glad to help where I can.

I've been starting it in 35-40 deg weather and it does great. It somokes a lot and runs slow for about 3-4minutes and then clears itself out. I'm thinking i'll tweak the rail travel on the pump down a little but more. Smoke goes away when things get going. Now if it would just heat up. Perhaps a ball valve in the hot water tank circuit.

Mark, I've been reading your posts on rebuilding the MD17C. I have a 1982 S2 11.0 with this engine and it currently has a stuck rod on the injector pump. Considereing all option. If you had to do it over and rebuild again would you? Would you mind sharing the total cost and sources of parts?

Hi Bruce. There are basically three reasons why I decided to rebuild. 1)I did 95% of the labor myself..2) There were only 2400 hrs on the engine.. and 3) it is (and has been) a fresh water cooled engine. I had a sistership in the mid 80s and I did the same thing back then as the PO had neglected it (and it was raw water cooled. So, I knew how to do it and I've also rebuilt several car engines. I basically had it apart in a few hrs. I was only planning on valves/rings but decided to go farther based on markings on the liners and I did have some slap. The cooling system was still "immaculate". I also had the injector pump rebuilt which I was not planning on doing. I also replaced the high pressure fuel lines as two of mine were rusting quite bad. The heat exchanger is mounted just above them off the manifold. As for cost/parts, I probably spent 5K total but I did not keep a dollar by dollar accounting. And, keep in mind, I did not get into the crank/cam. I also had some labor done when I was laid up with foot surgery. My parts came from Marine Parts Express in Maine. I think they have the best prices that were seemingly better than the local Volvo dealer. The only parts that were not available are the high pressure fuel lines. volvo does not make them anymore and I could not find them amongst dealers I called. They referred me to a place in NY (which I for the life of me cannot remember the name but I can find out) that has them made up. And actually, I bought my head gasket kit from them at half the price. The only other part I know of that is not available are the copper injector sleeves in the heads. I bought the last three just in case I needed them. I didn't but saving for the future. Otherwises it's a new or used head. The injector pump is about $2K but you can get it rebuilt for about $400. When you take the pump off, try and save the gaskets or at least try not to destroy so you can determine how many were used. These determine timing. I'm sort of curious as the "stuck rod on injector pump". There are rollers on each cyclinder of the pump that actuate the cylinder when the cam lobe shows up. Is a pump cyclinder seized? If so, I think I'd inspect that cam lobe carefully. Let me know if you need anything else....MMark, I've been reading your posts on rebuilding the MD17C. I have a 1982 S2 11.0 with this engine and it currently has a stuck rod on the injector pump. Considereing all option. If you had to do it over and rebuild again would you? Would you mind sharing the total cost and sources of parts?

Just read the bit about the leaky exhaust elbow. It appears to be the last item on our quest to find the source of the overheating on the raw water cooled MD17C. It has been in fresh water it's whole life, except for about 9 months. Would we notice any leaks while the engine was running....there are no visible leaks. Putting a hose to the highest hose on the hot water heat exchanger gives us great water flow out the exhaust, would that indicate a healthy elbow? New thermostat, impellar checked out, all hoses checked come out clean. Would one of those infrared temp readers give us a better idea of the raw water temp? Suggestions welcome.

Hmmm.... I would not hook the "hose" to any part as you might fill up the cylinders. This is a pretty simple circuit. Measuring different parts of the circuit with an infared thermometer is a good idea. You can buy a cheap one at Harbor Freight or other places...Measure different places on the exhaust manifold and different places on each cylinder, t-stat housing and the elbow. This will also verify your temp gauge readings. I'm also assuming the raw water inlet from the "outside" is clear with no collapsed hoses or plugged strainers. You can remove the hose from the manifold and stick it in a container and start the engine and look at the flow. Also, the exhaust hose from the elbow to the transom could be collapsing somewhere. Does the engine seem to lose power? City water pressure is not a good test here. I had this same boat/engine 30+ yrs ago (RWC). That's about when Volvo changed their T-stat design. They went form a bellows design to a wax design which didn't work. I ended up drilling a 3/16 hole in it. I'm assuming they have that fixed. Have you run it with the t-stat removed? You can also have the manifold removed in about 1/2 hr. It might be worth the cost of gaskets to have a look-see.....And I'm assuming you have the right temp t-stat for raw water cooled?

Mark, thanks for the suggestions. We seem to have good water flow throughout, and at neutral and idle at the dock great water output through the exhaust. It seems to be a little less when we put a load on the engine and increase the rpms, but still good flow, comparable to what we've had prior to this problem. When we initially noticed the overheat, we found some restrictions in the intake and cleared those. We also found some pretty good scaling inside the thermostat housing and cleared that and purchased a new thermostat. Ran a descaling solution through the engine, minus the new thermometer. We were advised against running the engine without the thermostat as we were told it could scar the cylinders or something. I suppose we could do that at the dock, it wouldn't be for long....the temp gauge goes up pretty fast under load. someone else suggested with us clearing and checking all the hoses there might be an airlock. With the good exhaust water output, do you think this could be part of the problem? As you suggested, our next step is to get an infrared read on the places you mentioned. Should they all be roughly the same at each location? We were told that Volvo's thermostats should open at 140 degrees F.Hmmm.... I would not hook the "hose" to any part as you might fill up the cylinders. This is a pretty simple circuit. Measuring different parts of the circuit with an infared thermometer is a good idea. You can buy a cheap one at Harbor Freight or other places...Measure different places on the exhaust manifold and different places on each cylinder, t-stat housing and the elbow. This will also verify your temp gauge readings. I'm also assuming the raw water inlet from the "outside" is clear with no collapsed hoses or plugged strainers. You can remove the hose from the manifold and stick it in a container and start the engine and look at the flow. Also, the exhaust hose from the elbow to the transom could be collapsing somewhere. Does the engine seem to lose power? City water pressure is not a good test here. I had this same boat/engine 30+ yrs ago (RWC). That's about when Volvo changed their T-stat design. They went form a bellows design to a wax design which didn't work. I ended up drilling a 3/16 hole in it. I'm assuming they have that fixed. Have you run it with the t-stat removed? You can also have the manifold removed in about 1/2 hr. It might be worth the cost of gaskets to have a look-see.....And I'm assuming you have the right temp t-stat for raw water cooled?

temp readings are going to be different. Where water enters the manifold, it's going to be cooler. Even one cylinder is going to exhibit different temps as you go up or down. I would think the T-stat housing should sorta mimic the t-stat settings. BTW, are you sure you have the raw water t-stat? I would be about 30 deg cooler than the FWC T-stat. (guess). Not sure about the issue of running without the T-stat. You could always sacrifice one and drill a hole through it to see if it makes a difference. It's all about flow and control of flow. I'm assuming it has worked in the past?

Mark, thanks for the suggestions. It would appear that the old thermostat was probably not working properly. We questioned the new one because the gauge acted differently, and it is only a bar gauge with red and green bars and a pointer. So we had our buddy with the infrared gun check over the whole engine and it is running per the specs. The third cylinder is a bit hotter, but he says that is normal as it is farther from the thermostat. Readings around the thermostat and manifold are all within range. So we are going to replace the sending unit with a new one since it isn't costly, and given the condition of the old thermostat, seems like a good idea.

BUT then, when we checked the oil, I saw a slight milky look to it. YIKES! So we are going to change the oil, run it at the dock a bit, and hope that the condition is the result of forcing water through the exhaust from the engine outflow. Or... It may be that the head gasket is failing from when we were out on the lake and it overheated. At any rate, we are prepared to make the correct fix. To answer your question, yes it is the correct thermostat for raw water cooled. I confirmed that through research and two different Volvo repair dealers. I know it makes a significant difference.

BUT then, when we checked the oil, I saw a slight milky look to it. YIKES! So we are going to change the oil, run it at the dock a bit, and hope that the condition is the result of forcing water through the exhaust from the engine outflow. Or... It may be that the head gasket is failing from when we were out on the lake and it overheated. At any rate, we are prepared to make the correct fix. To answer your question, yes it is the correct thermostat for raw water cooled. I confirmed that through research and two different Volvo repair dealers. I know it makes a significant difference.

check the seal for the impeller of the raw water pump. If that's worn, raw water can get into the crankcase. If it hasn't been done, I'd do it anyway..... If a head gasket is bad, I would think you'd have some white smoke.

you have to pull the pump out and take it apart. It is a seal that the shaft goes through behind the impeller.

Well, before we got your reply above Mark, we went with some bad advice and hooked up the hose at low pressure and ran it through. Great flow. Then the infrared readings with the new thermostat came out okay. But of course now we have milky oil, and have changed it out twice, including the filter. Your earlier post suggested we may have filled up the cylinders. Running at the dock under slight load, we still had clear oil, so we headed out. About a mile out, running under our normal cruising rpms of about 1900 rpms, the engine lost power and died. We sailed it back into the slip and found milky oil. Just as a quick test, we started the engine and it started right up. We have decided not to play amateur mechanic anymore, but what are your thoughts on this? Blown head gasket or do you think there is a simpler check or fix for a mechanic to try first?Hmmm.... I would not hook the "hose" to any part as you might fill up the cylinders. This is a pretty simple circuit. Measuring different parts of the circuit with an infared thermometer is a good idea. You can buy a cheap one at Harbor Freight or other places...Measure different places on the exhaust manifold and different places on each cylinder, t-stat housing and the elbow. This will also verify your temp gauge readings. I'm also assuming the raw water inlet from the "outside" is clear with no collapsed hoses or plugged strainers. You can remove the hose from the manifold and stick it in a container and start the engine and look at the flow. Also, the exhaust hose from the elbow to the transom could be collapsing somewhere. Does the engine seem to lose power? City water pressure is not a good test here. I had this same boat/engine 30+ yrs ago (RWC). That's about when Volvo changed their T-stat design. They went form a bellows design to a wax design which didn't work. I ended up drilling a 3/16 hole in it. I'm assuming they have that fixed. Have you run it with the t-stat removed? You can also have the manifold removed in about 1/2 hr. It might be worth the cost of gaskets to have a look-see.....And I'm assuming you have the right temp t-stat for raw water cooled?