Can anyone give me a couple of pointers regarding my catalina 310. I bought the PYI shaft seal and a flexible coupling to install this weekend. I have read mainsails wonderfully detailed instructions and have come up against a couple of problems.

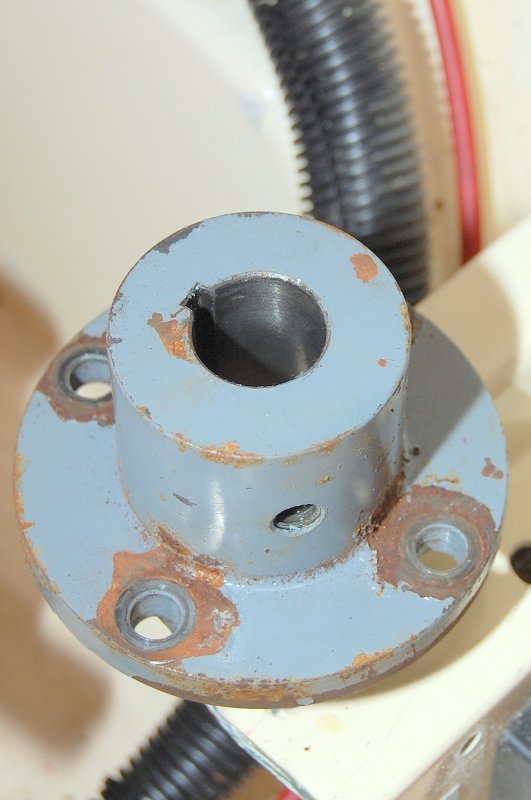

There is not very much room between my shaft log and my transmission coupling.By the time you put on the PYI seal and rotor there is only a small space to get the shaft lined up to the installed shaft couplings mated on the transmission coupling. My problem is how do you get the shaft onto the shaft coupling. If you look at Mainsails pictures you can see that there is very little room and so how do you get the shaft to go into the shaft coupling. There is no room to tap the coupling towards the stern. So I bought a split coupling and plan on tapping the shaft at the prop end with a block to push the shaft into the coupling. Is this going to hurt my transmission.

In mainsails directions he says not to hit the shaft towards the transmission when it is connected to the transmission, but in #4 he stated that you have to tap it home with a rubber mallet in order to get the shaft into the coupling. Is this a conflict and if not do I have to worry because I have a split coupling.

There is not very much room between my shaft log and my transmission coupling.By the time you put on the PYI seal and rotor there is only a small space to get the shaft lined up to the installed shaft couplings mated on the transmission coupling. My problem is how do you get the shaft onto the shaft coupling. If you look at Mainsails pictures you can see that there is very little room and so how do you get the shaft to go into the shaft coupling. There is no room to tap the coupling towards the stern. So I bought a split coupling and plan on tapping the shaft at the prop end with a block to push the shaft into the coupling. Is this going to hurt my transmission.

In mainsails directions he says not to hit the shaft towards the transmission when it is connected to the transmission, but in #4 he stated that you have to tap it home with a rubber mallet in order to get the shaft into the coupling. Is this a conflict and if not do I have to worry because I have a split coupling.