Thanks cloudDiver I'm sure I'll figure something out when it comes time to do the glass and prep in there. I'm going to wait till spring probably unless the trailer and bottom paint goes better/faster than expected.

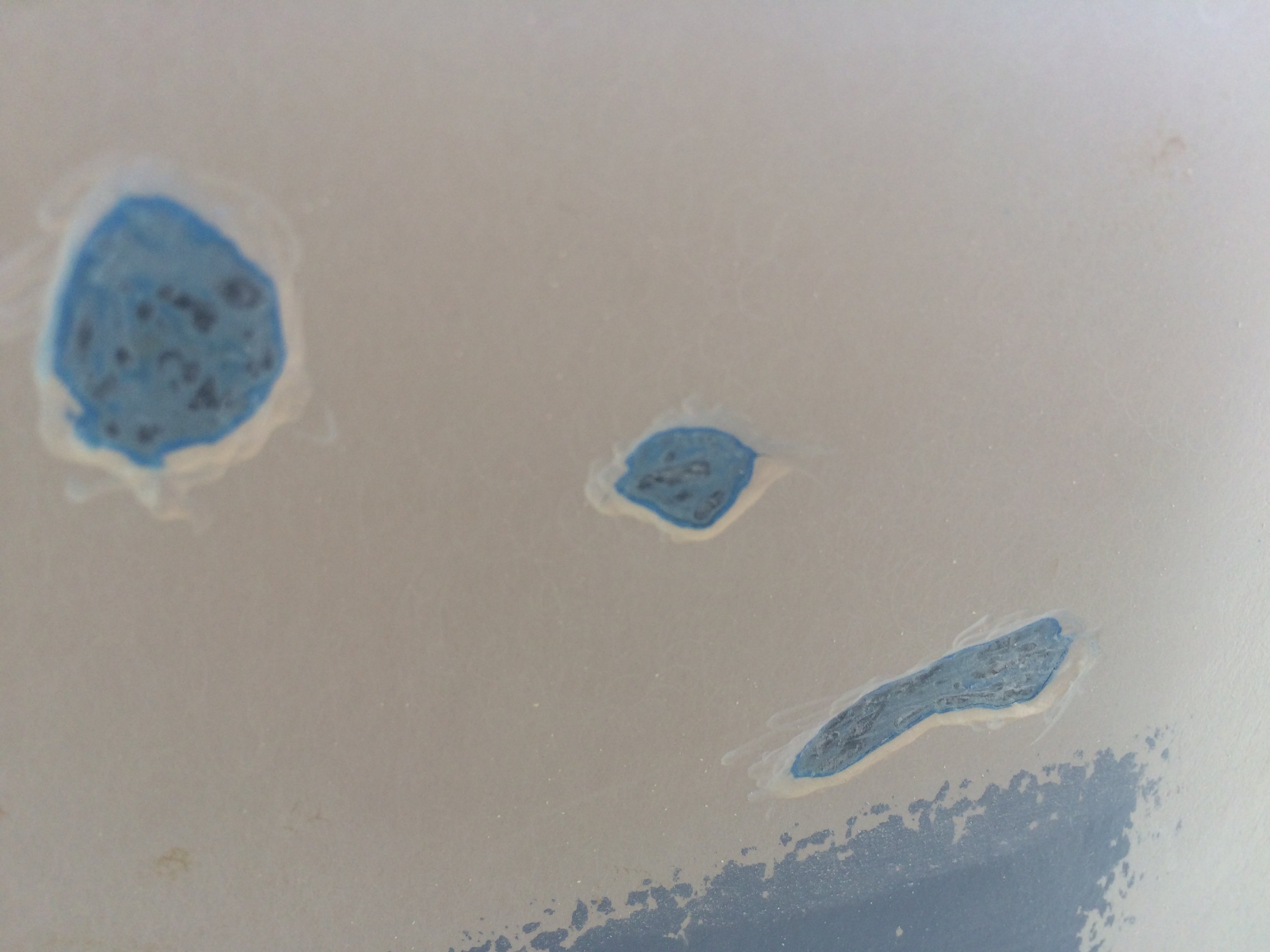

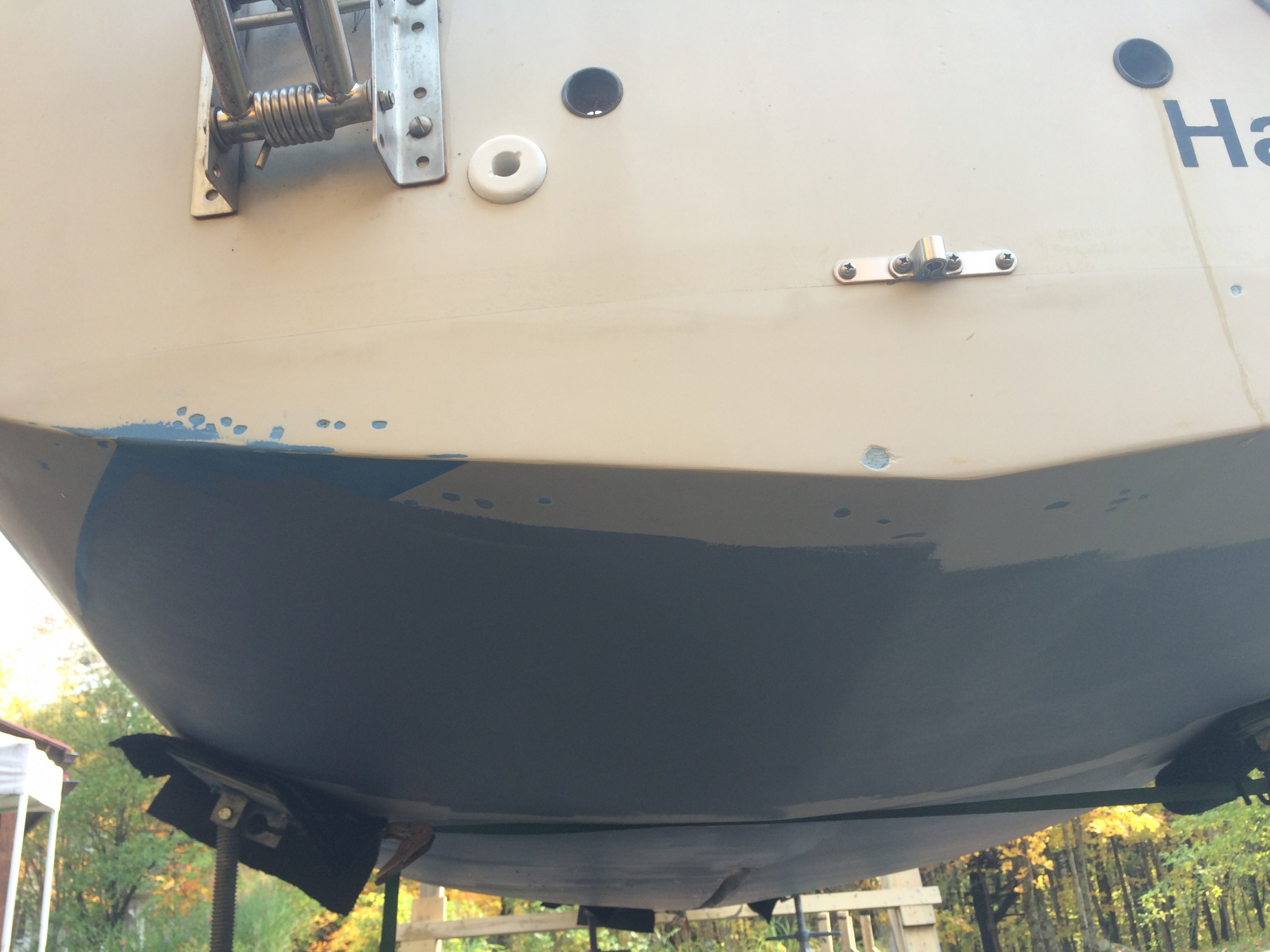

I saw some cracks in the bottom of the boat at the back and decided to grind them out today. Ended up finding some fairly large voids bewtween the glass and the gel. There were also some small air bubble holes so I just opened them up a bit for better end results.

I'm not sure what to fill with. Might use bondo-glass filler. Or might use west with 406 and 407.

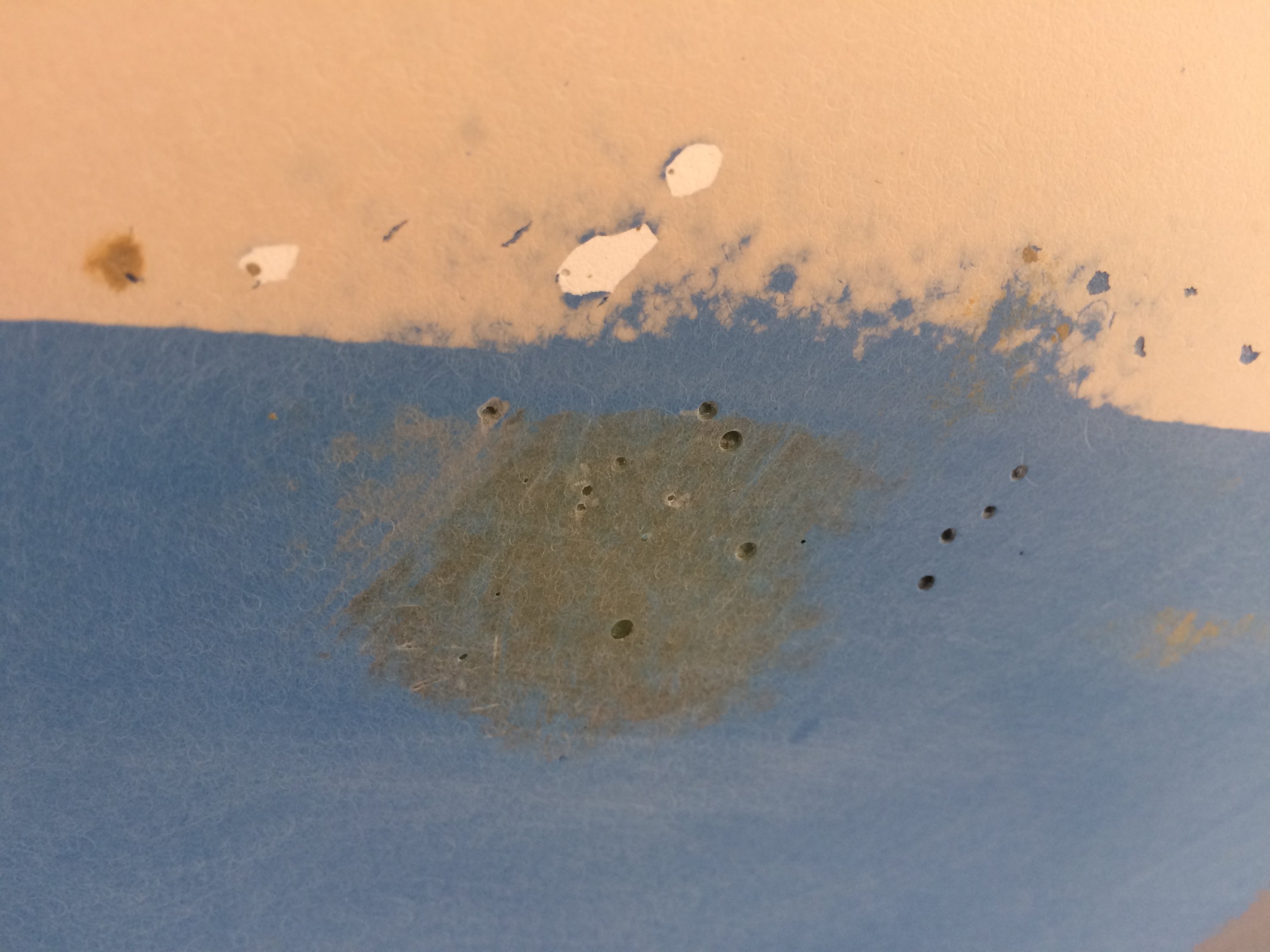

It looks like I could go further with the voids but I don't want to get carried away. If you look at the bottom ground section in the third picture you can still see a little void but I think the filler will take care of that

What do you think?

I saw some cracks in the bottom of the boat at the back and decided to grind them out today. Ended up finding some fairly large voids bewtween the glass and the gel. There were also some small air bubble holes so I just opened them up a bit for better end results.

I'm not sure what to fill with. Might use bondo-glass filler. Or might use west with 406 and 407.

It looks like I could go further with the voids but I don't want to get carried away. If you look at the bottom ground section in the third picture you can still see a little void but I think the filler will take care of that

What do you think?