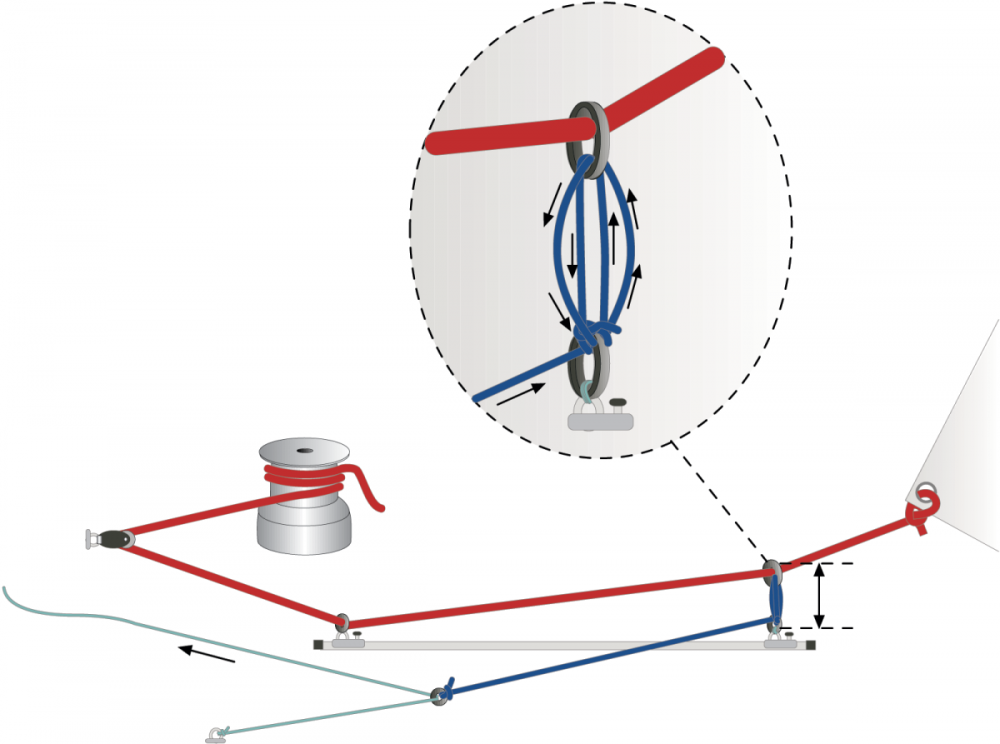

My 78 H30 doesn't have tracks and has blocks mounted on the toe rail for the Genoa sheets. I would like to rig twigs with friction less rings with a mechanical advantage to the toe rail to haul in the ring (down) for light winds and release it (up) for heavy winds allowing the rear sheave to dictate the sheet angle. I have seen this on a lot of racing boats and I think it is a good compromise for a track system that won't work on my boat due to the sheets being outside of the stays. I am interested in any input on experiences with this set up. What worked and what didn't. I figured I would make the twig a 3:1 and add a clam cleat after to secure it. I would use a ring for the sheet with blocks for its downhaul (not like the picture)

Genoa Twing Rigging

- Thread starter MikeHoncho

- Start date

Do you mean "twings", not twigs?

The idea is sound, but the devil is in the details of how you execute it and what hardware you use.

If you use blocks instead of the rings shown in the picture, the blocks will be flogging violently when the twing line is loose or when it's on the lazy side. The blocks will gouge the surfaces of the sidedeck and the cabin.

It's not clear to me exactly where you propose to use a clam cleat... but... don't forget that clam cleats jam easily and the line can't be released under load.

The idea is sound, but the devil is in the details of how you execute it and what hardware you use.

If you use blocks instead of the rings shown in the picture, the blocks will be flogging violently when the twing line is loose or when it's on the lazy side. The blocks will gouge the surfaces of the sidedeck and the cabin.

It's not clear to me exactly where you propose to use a clam cleat... but... don't forget that clam cleats jam easily and the line can't be released under load.

Mike... I think you are also talking about a Barber Hauler.

http://www.nauticed.org/sailing-blog/how-a-barber-hauler-works/

You can do it as you suggest. You can also carry a snatch block. If your aft block is not the right angle you attach the snatch block to the jib sheet and then locate it along the rail where the line needs to be.

http://www.nauticed.org/sailing-blog/how-a-barber-hauler-works/

You can do it as you suggest. You can also carry a snatch block. If your aft block is not the right angle you attach the snatch block to the jib sheet and then locate it along the rail where the line needs to be.

Each sheet has two blocks. I'll have to take a look and see if the forward one is a snatch block. I've only had the boat for a couple months.

I don't have a track/car. The genoa sheet goes through blocks fixed to the toe rail. The twing proposed is to adjust the height of the sheet when a higher angle is needed for heavier wind from where the block is now instead of moving the block back.

OK.. and that can work... What most often happens is the need to angle the sail based upon the line coming to the rail. The angle is changed not by moving it up and down (creating a compound angle, but by moving the block forward and aft. This brings the line from the clue down at varying angles that stretches the luff to varying degrees. It then moves the power point of the sail forward to aft. Kind of like having twings at multiple places along the toe rail. What you use as attach points may vary. The base of a stanchion, a padeye, an opening in the toe rail... etc.

You can do it with the frictionless rings and a dyneema line tied to the strong point as well. On my small boat I used the frictionless rings by Antal for the spinnaker sheets. Worked great.

Or you can use the clip on snatch block.

It does not need to be a fixed ring. Move it about as needed. A lot easier and simpler.

You can do it with the frictionless rings and a dyneema line tied to the strong point as well. On my small boat I used the frictionless rings by Antal for the spinnaker sheets. Worked great.

Or you can use the clip on snatch block.

It does not need to be a fixed ring. Move it about as needed. A lot easier and simpler.

Okay... I get it. You can't adjust your jib/genoa lead for and aft.... and you're looking for an alternative way to adjust the sheet's angle to the clew.I don't have a track/car. The genoa sheet goes through blocks fixed to the toe rail. The twing proposed is to adjust the height of the sheet when a higher angle is needed for heavier wind from where the block is now instead of moving the block back.

First of all, I don't think this will work as well as you expect because the vertical travel will be quite limited and the clew angle will not change that much. But you can try it....

I would not bother with all the purchase and rings... too complicated...at least until you know if it will work. I suggest you use a single block with a becket for the sheet to pass through...the becket is for a piece of shock cord you attach to the lifeline to hold the block upright.... The control line runs from the top block down to the block on the deck then back to a cleat, Your choice on the cleat. So all you spend is for a simple block with a becket, a length of polyester line and a cleat. If it works the way you hope, then that would justify all this other stuff you've sketched out.

For now you can set the device by luffing up to take tension off the sheet... or you can use a spare winch if you have it.

Here's a question. What is the difference between moving the jib lead fore and aft to adjust the clew angle and simply raising the lead vertically???? What becomes blatantly obvious is that although there will be tension changes on the leech... there will be very little effect on the foot. Can you visualize that? Don't you think it would help if you could put ANOTHER control line on the floating block that would also pull it forward? It's getting complicated, isn't it...

If your current blocks are fixed, I'd suggest to move to snatch blocks so they can easily be moved along your toe rail. Your toe rail has a lot of holes so you can get a lot of adjustment that way. I agree with DrJudy in that if you start getting more complicated, you are moving into a difficult to control system that may well flog your boat. Plus all the complications of the lines etc, and that's on both sides of your boat.

dj

dj

My thought was to place the ring rigging forward on the toe rail in a place good for light wind and a aft block proper for heavy like described above. When on heavy wind I could release the ring rigging, allowing the ring/sheet to rise and conform to the aft block angle. Maybe I'm missing something?

Thanks for the input. I'll mull it over some more. Probably just revert back to moving the forward block on the windward side as needed .

So I set it up today like the picture I first posted but went with a 3:1 between the two rings.

There was light winds so i was able to set it up a little bit not enough around for consistent performance. With the ring system soft shackled foward off the clew location on a beam reach, the system worked well to adjust the slot and also adjust the twist off by tightening up the luff. No flogging of any of it when I released tension on the system because the ringa would slide down the sheat and sit on the gunwale. The whole system is attached to the toe rail so it it outside of the lifelines so it cant hit the cabin of the boat. More to come and I'll hey some pictures.

I used this project to learn how to slice braid on braid and also how to build soft shackles out of Dyneema. Fun project. Cost about $150.

There was light winds so i was able to set it up a little bit not enough around for consistent performance. With the ring system soft shackled foward off the clew location on a beam reach, the system worked well to adjust the slot and also adjust the twist off by tightening up the luff. No flogging of any of it when I released tension on the system because the ringa would slide down the sheat and sit on the gunwale. The whole system is attached to the toe rail so it it outside of the lifelines so it cant hit the cabin of the boat. More to come and I'll hey some pictures.

I used this project to learn how to slice braid on braid and also how to build soft shackles out of Dyneema. Fun project. Cost about $150.

Took it out in 20 knot winds today. The system works better than expected needing little input to effect the tightening of the luff. I moved the sheet blocks back so the balance on the genoa is towards the foot being tight that way I can give in little input on the twing and the luff is tightened. Seems to work well.