When it comes to selecting an autopilot, if your boat has a displacement weight less than 16,500 lbs, the Raymarine EV-100 is a likely option under consideration. It was the primary option when I explored my first AP.

Now that I am 5 years into use with about 2000 nm usage I have had to do a major repair on the 4000Mk2 Wheel drive.

For the past year I have been experiencing failures of the drive to function. This is not a problem when I have fellow cruisers sharing the load of Helm Watch. As a solo sailor there is a dependency that develops between the AP and the Skipper/Crew. When the AP acts up there are issues.

First to go was the rubber boot that covers the power connection (Cable Plug) to the motor. Rubber rot. No replacement is available. Looking for an alternative replacement that I can slip over the cord and keep water from easily corroding the motor.

About 18 months ago my trusty AP started to act erratic. It would work for a time then drift off course or not work at all. The ACU and Sensor elements of the system worked and worked well. This pattern was all associated with the 4000Mk2 Wheel drive.

Symptoms:

These would work for a time then not. When I inspected the lever I discovered that the plastic used for the original lever was rounding out (breaking down - slipping off the stops). The wheel drive design has a couple of plastic knobs that are intended to soft hold the clutch lever in place when operating. The lever did not fit over the nobs properly. So I sought out help from Raymarine. Even talked with the London based engineers for the AutoHelm Wheel drive design. Their solution was to package the drive up and send it to them. They would evaluate the problem and let me know the cost to do repairs. Bugger that.

I found i3DGear out of Canada. They were making a replacement clutch lever - guaranteed to fit. It's cost was about the shipping cost of my drive to Raymarine. I ordered one.

While it fit the gear system, it suffered from the same issue. The cut on the inside of the lever was not fitting over the nobs in the back cover of the wheel drive. I discussed the issue with i3DGear and a replacement was sent with a new improved design.

I was back in business for at least 200nm. Then the symptoms returned. I read about cleaning/lubrication of the drive, as sitting outside in the elements can cause deterioration and dirt build up. So I took the unit apart and cleaned the insides, then sparingly applied lubrication to the roller bearings around the drive wheel and the insides of the Clutch Roller. Taking care not to let the lubrication get on the drive belt or the belt side of the clutch roller.

Again I thought I had solved the issue. And I had until the system acted up again.

Yes a little frustration began to blind me. Maybe I was all wrong. Perhaps I need to consider a linear drive system. But I persevered and again opened up the 4000MK2 wheel to discover the new failure..

Maybe I was all wrong. Perhaps I need to consider a linear drive system. But I persevered and again opened up the 4000MK2 wheel to discover the new failure..

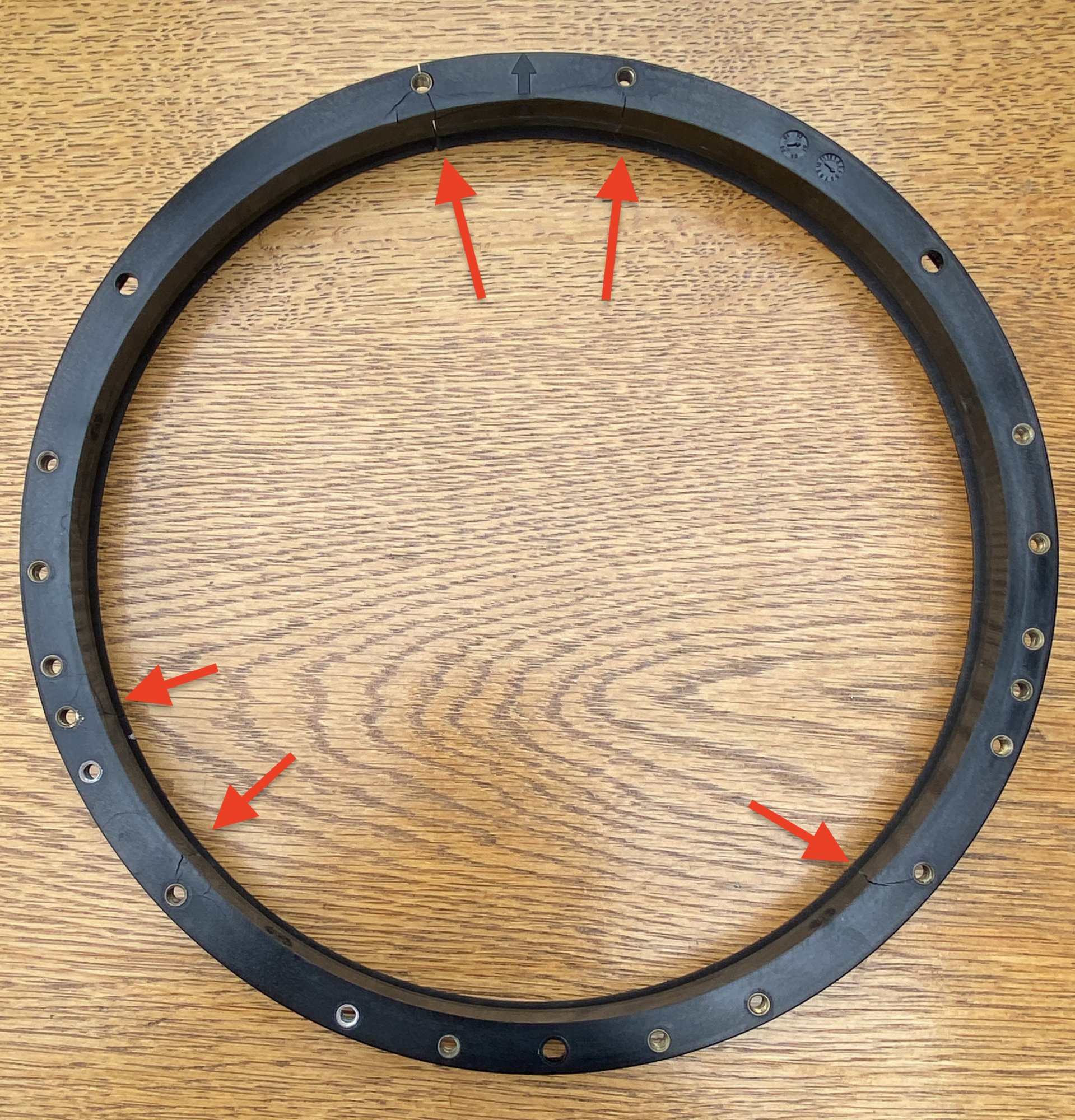

The Drive Ring (an essential part of the Wheel Drive) was cracked.

Not just a little failure - TOTAL FAILURE. I know it is plastic and decays, but when you spend over $1,000 for a boat part, I do not expect to see this type of decay of a critical part in such a short time frame.

To add insult to the problem, these drive rings (part# A18076 ) are not easy to find. Our Seattle chandler has them as a "Special Order" item. I found 1 in Denmark @ 795 DKK, 1 in Nova Scotia @ $120 CDN but when you list as a US buyer it is :This item is currently out of stock. No ETA date available. and cost to ship "Priceless". When you search Defender they switch your search criteria to the electric motor A18086.

Clearly the supply chain for this part is either being tightly controlled by Raymarine or they have run out of production and want to push their in house repairs. My take on the issue is the wheel drive design is flawed. The plastic used for the extrusion was either too thin or the material absorbs water and fractures when in use. Raymarine is running out of the original production run and may eventually the part will be unobtainable.

In summary:

I did find a replacement part that just arrived for under $100. I have cleaned the insides of the Wheel Drive, applied a dry lube to the parts identified.

I installed the drive ring. This was a little tricky. There are 21 ball bearing balls that encircle the unit and are held between the back cover and the drive ring by 3 "wheel bearing clips".

To get these in place, I placed the drive ring on the back cover and slipped the 21 bearings into the space between the back cover and the drive ring. I then started to put the 3 wheel bearing clips on the bearings between the back cover and the drive ring. The clips slide over and snap into place over the bearings as you work your way around the drive wheel. It was really quite easy once you decode the design and how it fits together.

Joy was the drive ring smoothly rotating around on the back wheel cover when the clutch is released. When the clutch is tightened the belt grabs the drive ring and moves when the drive motor is powered.

I will have the unit back in service for my next cruise.

I may start to explore other options for a powered autopilot as this design has some serious design issues and lacks long term reliability.

Now that I am 5 years into use with about 2000 nm usage I have had to do a major repair on the 4000Mk2 Wheel drive.

For the past year I have been experiencing failures of the drive to function. This is not a problem when I have fellow cruisers sharing the load of Helm Watch. As a solo sailor there is a dependency that develops between the AP and the Skipper/Crew. When the AP acts up there are issues.

First to go was the rubber boot that covers the power connection (Cable Plug) to the motor. Rubber rot. No replacement is available. Looking for an alternative replacement that I can slip over the cord and keep water from easily corroding the motor.

About 18 months ago my trusty AP started to act erratic. It would work for a time then drift off course or not work at all. The ACU and Sensor elements of the system worked and worked well. This pattern was all associated with the 4000Mk2 Wheel drive.

Symptoms:

- The clutch lever would slip. I tried:

- Tightening the lever screw

- taping the lever in place

- Wrapping a rubberband around the lever to hold it in place.

These would work for a time then not. When I inspected the lever I discovered that the plastic used for the original lever was rounding out (breaking down - slipping off the stops). The wheel drive design has a couple of plastic knobs that are intended to soft hold the clutch lever in place when operating. The lever did not fit over the nobs properly. So I sought out help from Raymarine. Even talked with the London based engineers for the AutoHelm Wheel drive design. Their solution was to package the drive up and send it to them. They would evaluate the problem and let me know the cost to do repairs. Bugger that.

I found i3DGear out of Canada. They were making a replacement clutch lever - guaranteed to fit. It's cost was about the shipping cost of my drive to Raymarine. I ordered one.

While it fit the gear system, it suffered from the same issue. The cut on the inside of the lever was not fitting over the nobs in the back cover of the wheel drive. I discussed the issue with i3DGear and a replacement was sent with a new improved design.

I was back in business for at least 200nm. Then the symptoms returned. I read about cleaning/lubrication of the drive, as sitting outside in the elements can cause deterioration and dirt build up. So I took the unit apart and cleaned the insides, then sparingly applied lubrication to the roller bearings around the drive wheel and the insides of the Clutch Roller. Taking care not to let the lubrication get on the drive belt or the belt side of the clutch roller.

Again I thought I had solved the issue. And I had until the system acted up again.

Yes a little frustration began to blind me.

The Drive Ring (an essential part of the Wheel Drive) was cracked.

Not just a little failure - TOTAL FAILURE. I know it is plastic and decays, but when you spend over $1,000 for a boat part, I do not expect to see this type of decay of a critical part in such a short time frame.

To add insult to the problem, these drive rings (part# A18076 ) are not easy to find. Our Seattle chandler has them as a "Special Order" item. I found 1 in Denmark @ 795 DKK, 1 in Nova Scotia @ $120 CDN but when you list as a US buyer it is :This item is currently out of stock. No ETA date available. and cost to ship "Priceless". When you search Defender they switch your search criteria to the electric motor A18086.

Clearly the supply chain for this part is either being tightly controlled by Raymarine or they have run out of production and want to push their in house repairs. My take on the issue is the wheel drive design is flawed. The plastic used for the extrusion was either too thin or the material absorbs water and fractures when in use. Raymarine is running out of the original production run and may eventually the part will be unobtainable.

In summary:

I did find a replacement part that just arrived for under $100. I have cleaned the insides of the Wheel Drive, applied a dry lube to the parts identified.

I installed the drive ring. This was a little tricky. There are 21 ball bearing balls that encircle the unit and are held between the back cover and the drive ring by 3 "wheel bearing clips".

To get these in place, I placed the drive ring on the back cover and slipped the 21 bearings into the space between the back cover and the drive ring. I then started to put the 3 wheel bearing clips on the bearings between the back cover and the drive ring. The clips slide over and snap into place over the bearings as you work your way around the drive wheel. It was really quite easy once you decode the design and how it fits together.

Joy was the drive ring smoothly rotating around on the back wheel cover when the clutch is released. When the clutch is tightened the belt grabs the drive ring and moves when the drive motor is powered.

I will have the unit back in service for my next cruise.

I may start to explore other options for a powered autopilot as this design has some serious design issues and lacks long term reliability.

There are things in the cockpit that are potential issues, but AP belts aren't one of them in my mind, because they are "inside" the wheel.

There are things in the cockpit that are potential issues, but AP belts aren't one of them in my mind, because they are "inside" the wheel.