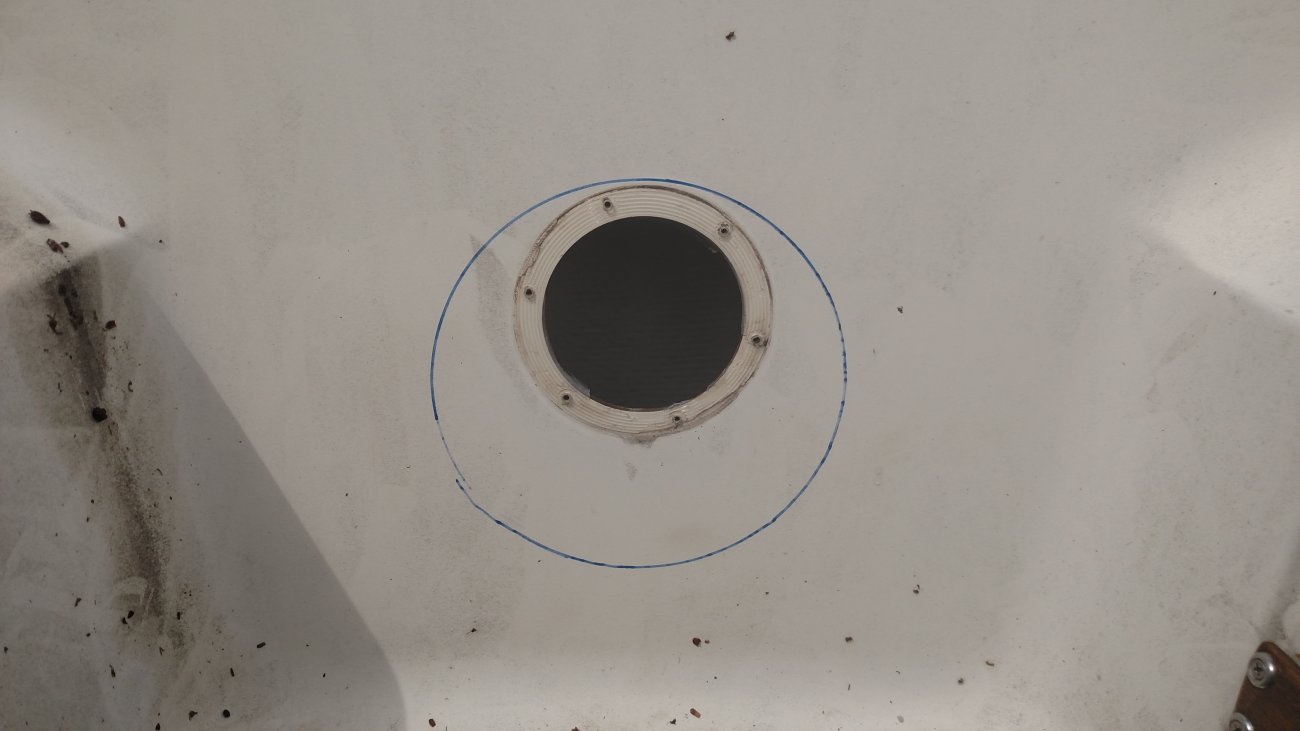

So, during inspection,found loose not on the lower rudder pintle, evidence of water leaking in also. The aft cockpit wall has a 4" inspection plate that allows me to see the nuts on inside but can't reach them. So, removed 4" today,insta inst 8" in place. Removed pintle. When I reinstall and seal it up I want to put in a backing plate instead of 2 factory washers. In know nothing of SS, what gauge, type, model # do I want to use?

S S backing plate info

- Thread starter DAVA390

- Start date

A key to strong backing plates is to avoid point loading. Square or round would be fine, however, if the backing plate is rectangular or square the corners should be rounded. The edges of the backing plate, either round or rectangular, should be eased so that the edge is not a sharp corner.

SS may be overkill on this. A 3/16"aluminum backing plate would be OK, just use some Tef-Gel on the SS bolts. SS would work, however, Aluminum is easier to work with. Practical Sailor has a series of articles on backing plates, most of them are only available to subscribers.

BTW, your boat and my Sabre 362 were both designed by Jim Taylor, a good pedigree.

SS may be overkill on this. A 3/16"aluminum backing plate would be OK, just use some Tef-Gel on the SS bolts. SS would work, however, Aluminum is easier to work with. Practical Sailor has a series of articles on backing plates, most of them are only available to subscribers.

BTW, your boat and my Sabre 362 were both designed by Jim Taylor, a good pedigree.

Hello Dave, Another one of those exciting moments in boat ownership…...Making bigger holes in your boat! That larger inspection plate might never be needed again for the same project, but it will make a great hiding place for whatever you want to hide.

Aluminum may be easier to work with than stainless steel but it will be a potential cause of corrosion due to dissimilar metals. For a part that small and the amount of effort to make it, I'd go with 316 stainless, 3/16" thick should do it. Just cut a rectangle, drill the holes and bolt it down. If you want to get fancy you could round the edges, but really, if you make it big enough (say, a width of 15 to 20 times the bolt hole diameter), the edges won't have any load so shape won't matter. I have heard G10 makes a good backing plate but it would have to be thicker, and I would prefer steel for a potentially large fluctuating load like a rudder. My main concern with G10 is creep, the tendency for a material to take a "set" or plasticly deform under load, combined with the cycling load, could cause the bolt to loosen over time. Preload on the bolt is the best resistance to loosening and material creep reduces preload. A good locking nut will help but I like extra insurance for critical functions.

Oh, and I used stainless backing plates when I installed new winches on my boat.

Oh, and I used stainless backing plates when I installed new winches on my boat.

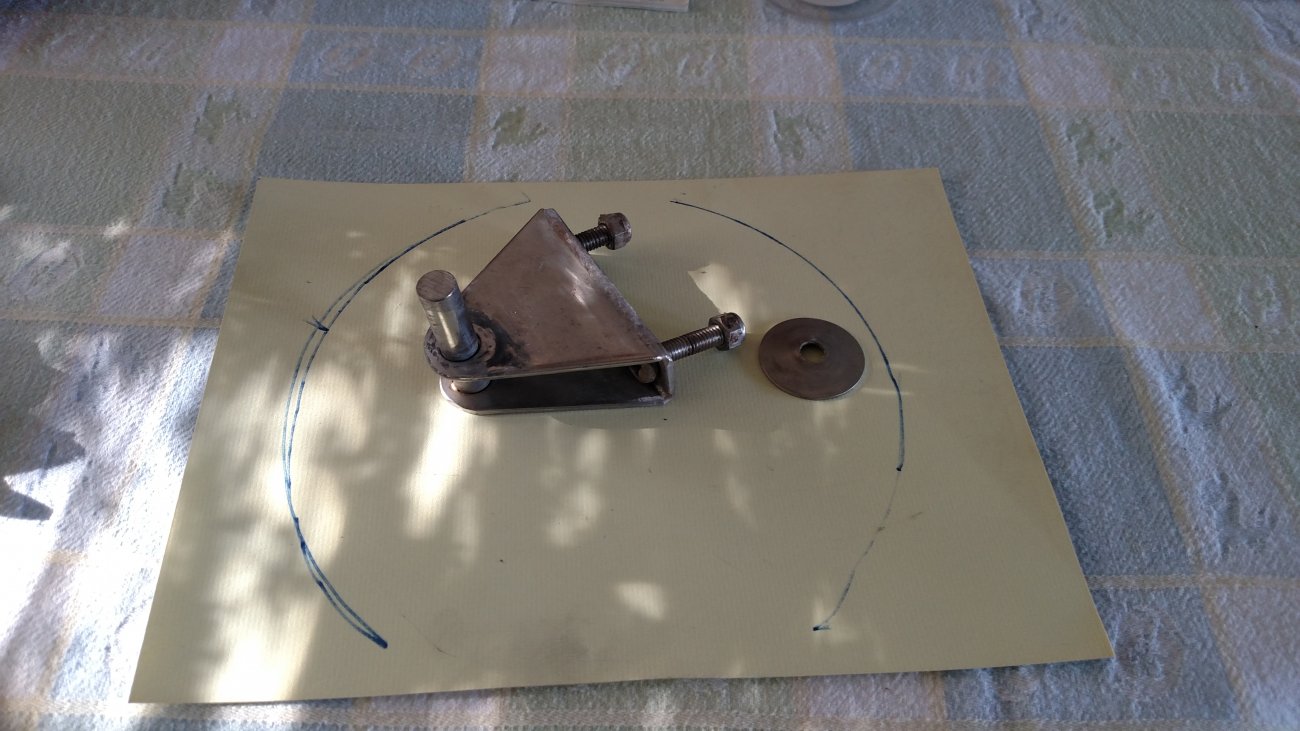

WhaT IS THE L X W FOOTPRINT OF THAT BRACKET?Ron, what do you mean by tang,,?

Attachments

-

142.5 KB Views: 100

I used to think all backing plates needed to be SS but then I discovered G-10. I now go with G-10 for backing plates that are out of site. I've even considered using black G-10 for backing plates that are visible. Easier to work than stainless and no corrosion issues. Epoxy it to the hull and you've increased the thickness of the hull in that area. I'd round the corners and edges that touch the hull to avoid point loading as Dave said.

G-10 is a much harder compressed fiberglass material than a fiberglass hull so I wouldn't be concerned about creep. 1/4" thickness should be fine but you can go thicker.

G-10 is a much harder compressed fiberglass material than a fiberglass hull so I wouldn't be concerned about creep. 1/4" thickness should be fine but you can go thicker.

DAVA390, I was thinking Easter eggs, a small cooler of soda, your own bag of Oreos, or something like that.

RE: backing plate......whatever you choose will probably be better than the fender washers that were there originally.

RE: pump gun......I thought the pirates of the Chesapeake had been pretty well subdued.

Happy Easter to you and to All.

RE: backing plate......whatever you choose will probably be better than the fender washers that were there originally.

RE: pump gun......I thought the pirates of the Chesapeake had been pretty well subdued.

Happy Easter to you and to All.

What is the thickness of the factory washers? Odds are they were standard fender washers, which are very thin. If you zoom in on the OP's photo, you can see that they are bent into a cone and distorted where the nut bore on it. This is VERY common and is the cause of the leak. These are useless as flies on sh_t and should not be sold in chandleries or used on boat. See recent article in Good Old Boat Magazine.

You can get "extra thick" fender washers on-line, which are double the thickness and 4 times the strength (It would take a stack of 4 standard washers to be as strong!) . This is what SHOULD have been used by the OEM and would have worked fine, since they will not bend.

That said, backing plates are even better.

But the standard fender washer is the problem, not the size. Order extra thick fender washers.

BTW, these are not unknown by boat builders. I seen them on higher quality boats.

You can get "extra thick" fender washers on-line, which are double the thickness and 4 times the strength (It would take a stack of 4 standard washers to be as strong!) . This is what SHOULD have been used by the OEM and would have worked fine, since they will not bend.

That said, backing plates are even better.

But the standard fender washer is the problem, not the size. Order extra thick fender washers.

BTW, these are not unknown by boat builders. I seen them on higher quality boats.

Last edited:

Phil, pump gun poor attempt at humor. Oreos likely won't make it from the truck to the boat. All: although the photos are poor quality, I can see large depressions ( cones?) From years of washers sucked in. I used goof off to soften up remaining ( presumed) 4200 surrounding the holes, scraped away call I could. Sanded the whole area and am planning to spread a thin layer of epoxy over the whole area then sand it and redrill the holes. Gonna use 3/16 or 1/4 SS plate, liberaliy apply fresh 4200 to it when placing against the hull. What say you all to that?

I dunnoHello Dave, Another one of those exciting moments in boat ownership…...Making bigger holes in your boat! That larger inspection plate might never be needed again for the same project, but it will make a great hiding place for whatever you want to hide.

An inspection plate sort of say HEY LOOK IN HERE

Sand all the paint/gelcoat off until you see raw fiberglass. Then lay up a couple of layers of fiberglass cloth (not mat) with epoxy, before drilling the holes.All: although the photos are poor quality, I can see large depressions ( cones?) From years of washers sucked in. I used goof off to soften up remaining ( presumed) 4200 surrounding the holes, scraped away call I could. Sanded the whole area and am planning to spread a thin layer of epoxy over the whole area then sand it and redrill the holes. Gonna use 3/16 or 1/4 SS plate, liberaliy apply fresh 4200 to it when placing against the hull. What say you all to that?

No need to bed the backing plate to the hull, bed the pintle with 4200 or 4000uv from the outside.