as usual lads-- you got me thinking:

1) you can google the crap out of epoxy resin and salt/fresh water interactions and read some pretty heavy stuff from real life scientists (Sandia Labs for starters: http://prod.sandia.gov/techlib/access-control.cgi/2009/094405.pdf) but in a nutshell I think we can safely say that epoxy resins in general are durable, far more durable for example than Gel Coat as anyone with blisters can attest to.

2) (regardless of what your shoulders and elbows tell you after sanding all day) Epoxy is not bullet proof-- and needs UV protection from the sun and a good barrier coat in the water.

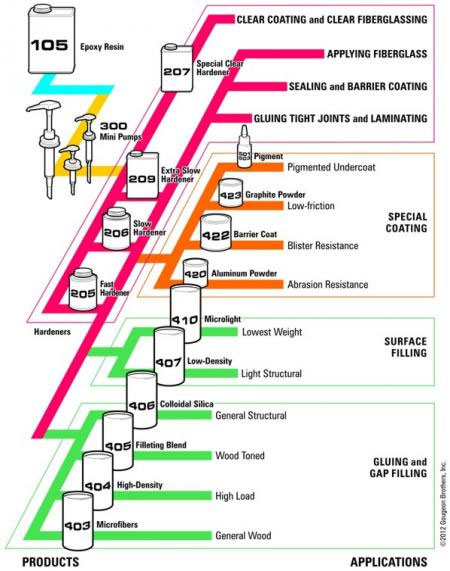

I personally wouldn't think twice about the multitude of the 4 different epoxy based blends I have on the Keel (205 / 410 / 406 / 407) and it will get barrier coated and swath of VC-17 for good measure. Note below that the Resin + Hardener guide alone denotes "sealing and barrier coating".

1) you can google the crap out of epoxy resin and salt/fresh water interactions and read some pretty heavy stuff from real life scientists (Sandia Labs for starters: http://prod.sandia.gov/techlib/access-control.cgi/2009/094405.pdf) but in a nutshell I think we can safely say that epoxy resins in general are durable, far more durable for example than Gel Coat as anyone with blisters can attest to.

2) (regardless of what your shoulders and elbows tell you after sanding all day) Epoxy is not bullet proof-- and needs UV protection from the sun and a good barrier coat in the water.

I personally wouldn't think twice about the multitude of the 4 different epoxy based blends I have on the Keel (205 / 410 / 406 / 407) and it will get barrier coated and swath of VC-17 for good measure. Note below that the Resin + Hardener guide alone denotes "sealing and barrier coating".