I need to purchase a few different diameters of rope or lines to be used to secure my dinghy out of the water to the transom. In the past I have purchased rope or line only to discover once it was cut burning the end did not stop the fray. So does anyone know what rope or line material can be successfully heat cauterized?

What type of rope or line can be cauterized

- Thread starter Jimongee

- Start date

Generally, what I do with either three strand or double braid synthetic rope to prevent it from fraying is:

1. Tight wrap the cut area with electrical tape.

2. Cut the rope in the center of the electrical tape.

3. Make a three quarter inch whip stitch up to about one eight inch from the end of the cut.

4. Use a flame to melt the very tip of the rope.

This has worked well over the years. Melting the tip alone works better with double braid than three strand, but after considerable use both will fray. Whip stitching over the electrical tape helps to stop fraying due to use or exposure to the elements.

1. Tight wrap the cut area with electrical tape.

2. Cut the rope in the center of the electrical tape.

3. Make a three quarter inch whip stitch up to about one eight inch from the end of the cut.

4. Use a flame to melt the very tip of the rope.

This has worked well over the years. Melting the tip alone works better with double braid than three strand, but after considerable use both will fray. Whip stitching over the electrical tape helps to stop fraying due to use or exposure to the elements.

Last edited:

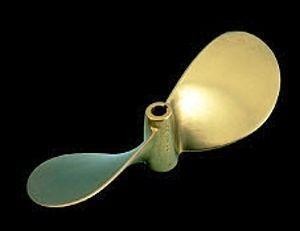

Hunter props, shafts, struts, and cutless bearingsAnd now a word from the sponsor...

See the product

Does nobody backsplice anymore?

For securing a dinghy to your transom, have you considered adjustable straps instead of rope? The way you wrote it, I'm guessing you aren't hanging your dinghy on davits.

-Will (Dragonfly)

For securing a dinghy to your transom, have you considered adjustable straps instead of rope? The way you wrote it, I'm guessing you aren't hanging your dinghy on davits.

-Will (Dragonfly)

After I whip the line with thread, I seal the whipping with Starbrite liquid line whip / sealer. It’s clear so it looks good and lasts for years. If it appears to be weathering, just re-coat.Years back I did most of my lines like Joe. Sadly the whipping line has started to unravel on some of the lines so I covered the whipping with shrink tube.

You can't just melt the ends of class 2 rope, covered in particular. Spectra does not melt well at all, and does so at a different temperature than polyester. The two will never adhere to each other.

I use a electric knife I got online from Walmart.com for 15 bucks; works great on Class 1 line. In all cases I put a lock stitch in the end to keep the core and cover together.

I use a electric knife I got online from Walmart.com for 15 bucks; works great on Class 1 line. In all cases I put a lock stitch in the end to keep the core and cover together.

My go-to resource for line information is APS - http://www.apsltd.com/line-resources

Click on the line, and they give you multiple factors including creep, stretch, water resilience, and MELTING!

I don't work there, just a happy customer. Not knocking our own SBO, just saying they have more info.

Click on the line, and they give you multiple factors including creep, stretch, water resilience, and MELTING!

I don't work there, just a happy customer. Not knocking our own SBO, just saying they have more info.

This is a good point. I have made a number of halyards and control lines with dyneema core and polyester cover. Lock stitching is mandatory and very easy. Every ten or fifteen feet is adequate. I still whip the non spliced end after lock stitching. I haven't tried the "liquid whip" products on the hybrid lines yet...You can't just melt the ends of class 2 rope, covered in particular. Spectra does not melt well at all, and does so at a different temperature than polyester. The two will never adhere to each other.

I use a electric knife I got online from Walmart.com for 15 bucks; works great on Class 1 line. In all cases I put a lock stitch in the end to keep the core and cover together.

Thanks for the tip. I covered a length of Dyneema which we use to pull the outboard up to the pushpit for traveling and the cover seems to stretch a little more with age. The Dyneema was a bit small and slippery so the cover makes it better on the hands and my wife can lead it to a winch so she can grind it up while I steady it from banging the boat.This is a good point. I have made a number of halyards and control lines with dyneema core and polyester cover. Lock stitching is mandatory and very easy. Every ten or fifteen feet is adequate. I still whip the non spliced end after lock stitching. I haven't tried the "liquid whip" products on the hybrid lines yet...