I have a leak in my cabin top which is going to require me to remove and re-bed the entire bridge section above my companionway hatch. As part of that process I will need to remove my Traveler. I have been having issues with the traveler due to its age, and some modifications that were made by one of the previous owners.

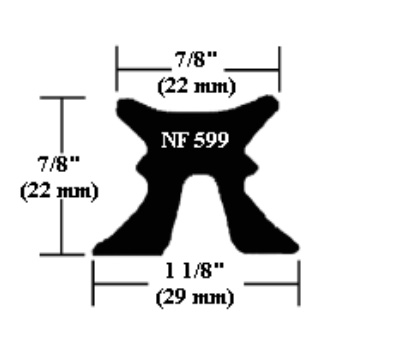

I have the Nicro-Fico NF 599 X Track system

NF 599 Traveller Track is a Black hardcote anodized Aluminum X-Track that measures 7/8" (22mm) across the top, 1 1/8" (29mm) across the base and is 7/8" high. Track is drilled for #10 (3/16") FH screws on 4" (102mm) centers, and has 5/16" diameter stop holes on 1" centers. NF 599 X-Track is available in 3', 4', 5', and 6-foot lengths, and lengths up to 20 feet.

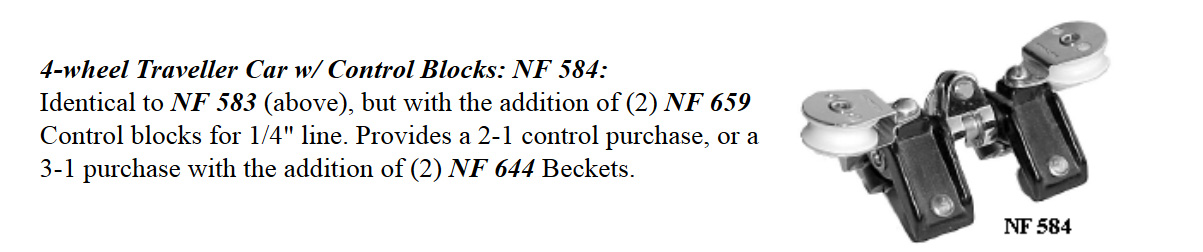

It uses an NF 584 Traveler Car

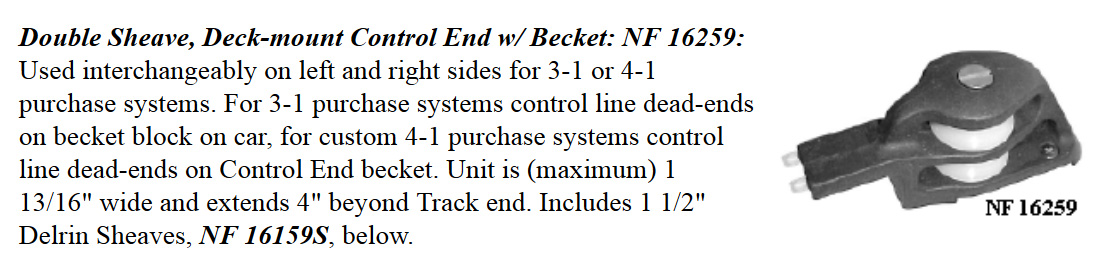

with NF 16259 Traveller controll ends

The two issues I have are

To reduce the effort of trimming the traveler, I am think of replacing the Delrin wheels on the car with sealed stainless roller bearings of the same size.

Sealed Bearing 1/4 x 11/16 x 5/16 inch Miniature Ball

The replacement wheel for NF 599/600 Traveler Cars is the NF 583W. It is a black Delrin wheel <11/16" diameter x <3/8" wide x 1/4"

Do you guys think Stainless bearings running on an anodized aluminum track will cause problems?

I may also try to find roller bearing sheaves for the control ends.

I have the Nicro-Fico NF 599 X Track system

NF 599 Traveller Track is a Black hardcote anodized Aluminum X-Track that measures 7/8" (22mm) across the top, 1 1/8" (29mm) across the base and is 7/8" high. Track is drilled for #10 (3/16") FH screws on 4" (102mm) centers, and has 5/16" diameter stop holes on 1" centers. NF 599 X-Track is available in 3', 4', 5', and 6-foot lengths, and lengths up to 20 feet.

It uses an NF 584 Traveler Car

with NF 16259 Traveller controll ends

The two issues I have are

- The previous owner moved the cam cleats from where they should have been attached to the control ends using the NF 16459A Control Plate Assembly and mounted them on the cabin top so that they would lead under the dodger he had added. This causes them to pop out of the cam on their own way too often. (see top picture)

- The amount of force it takes to trim the traveler under sail. There is way too much friction

To reduce the effort of trimming the traveler, I am think of replacing the Delrin wheels on the car with sealed stainless roller bearings of the same size.

Sealed Bearing 1/4 x 11/16 x 5/16 inch Miniature Ball

The replacement wheel for NF 599/600 Traveler Cars is the NF 583W. It is a black Delrin wheel <11/16" diameter x <3/8" wide x 1/4"

Do you guys think Stainless bearings running on an anodized aluminum track will cause problems?

I may also try to find roller bearing sheaves for the control ends.

Last edited: